Sliding block guiding hydraulic cutting knife

A formal and hydraulic technology, applied in wellbore/well components, earthwork drilling and mining, etc., can solve problems such as poor cutting effect, low success rate and sequence, and high labor intensity of manual operators, achieving high success rate and compact structure , small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

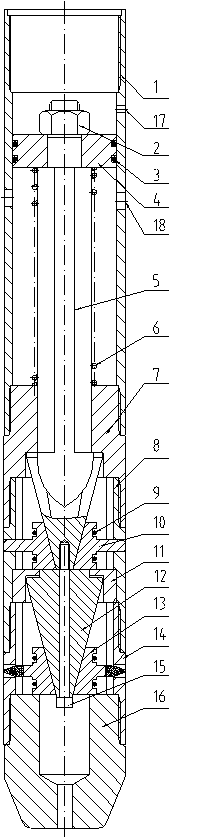

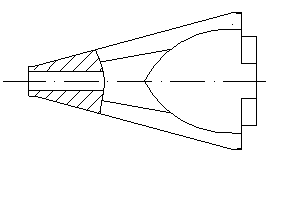

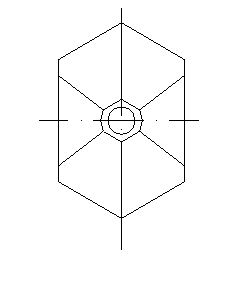

[0015] Example 1, see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , processed into short pipe 1, spring seat 7, guide body 8, knife rest 14, guide head 16, and the five are connected with threads; overflow hole 17 and pressure relief hole 18 are set on the wall of short pipe 1, overflow Orifice 17 is to prevent the mud pump pressure from being too high, and pressure relief hole 18 is to relieve pressure when the pipe is cut; a piston 4, a spring 6 and a piston rod 5 are installed in the short pipe 1, and the top of the piston 4 and the piston rod 5 passes through The bolt 2 is connected, the spring 6 is set outside the piston rod 5, and is located between the piston 4 and the spring seat 7, the piston 4 can slide up and down in the short tube 1 under the action of hydraulic force and elastic force, and the spring 6 can make the piston 4 return, An O-ring 3 is installed between the piston 4 and the short tube 1; a guide block 10, a vertebral body 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com