Tilting-pad water-lubricated rubber alloy bearing

A rubber alloy, water-lubricated technology, used in the field of bearings, can solve problems such as large friction, wear vibration and noise, force and torque imbalance, etc., to reduce vibration and noise, improve force conditions, and save use costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

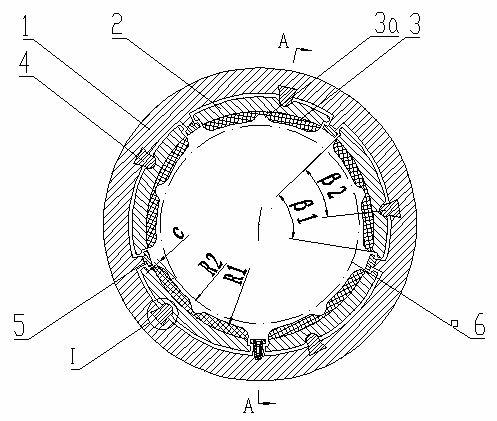

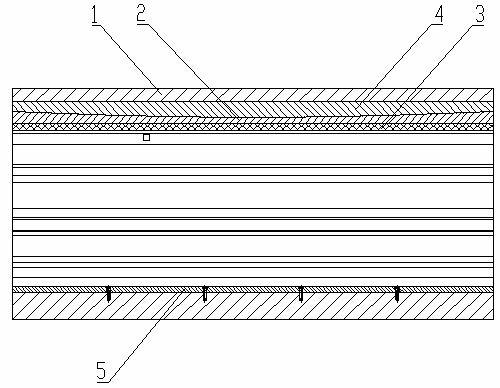

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings, as shown in the figure: the tilting pad type water-lubricated rubber alloy bearing of this embodiment includes a shaft housing 1, bearing pads 2 uniformly distributed in the shaft housing 1 along the circumferential direction and fixed The rubber alloy lining 3 bonded to the inner side of the bearing bush 2 generally has more than 3 bearing bushes. This embodiment adopts 5 bearing bushes, and the inner wall of the axle housing 1 is fixed with supports arranged axially and uniformly distributed along the circumferential direction. Bar 4, the support bar 4 corresponds to the bearing bush 2 one by one, the top cross section of the support bar 4 is circular, the outer side of the bearing bush 2 is provided with an axial groove 2a with a circular cross section, and the top gap of the support bar 4 Cooperate with the embedded groove 2a to form a tiltable structure in which th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com