Rake type dryer

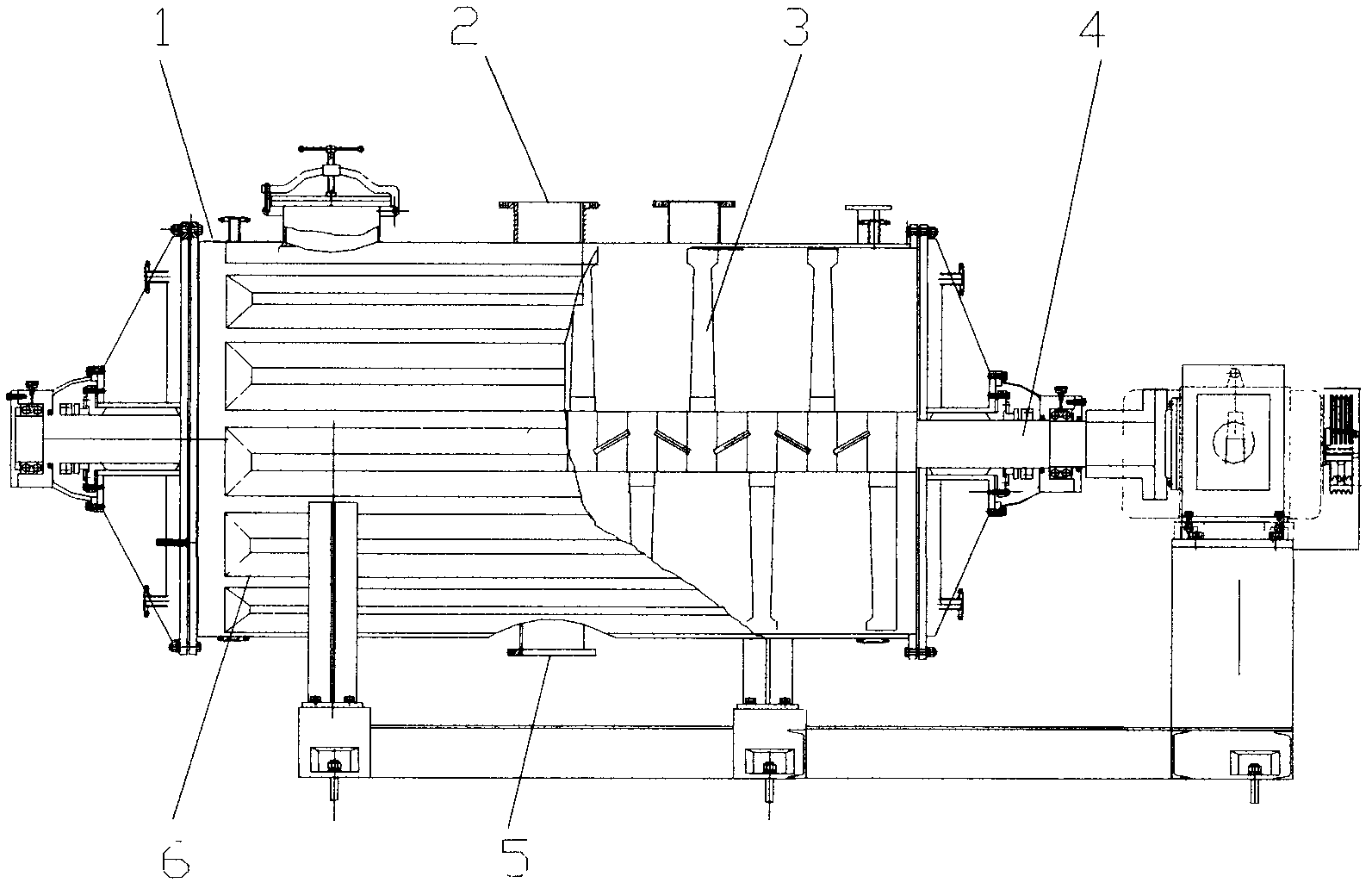

A rake dryer and drying chamber technology, which is applied in the direction of dryers, drying solid materials, drying chambers/containers, etc., and can solve the problems of low drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

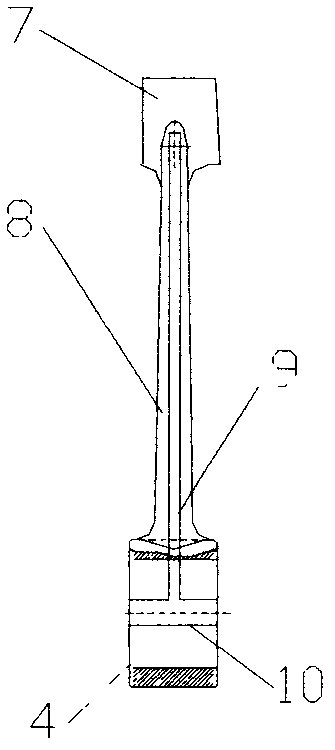

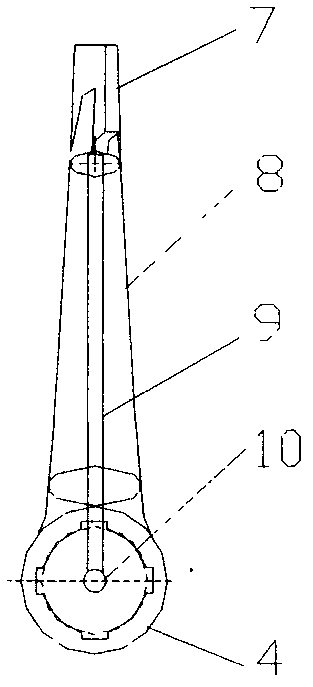

[0020] The rake head 7 is T-shaped.

[0021] The projection of the rake head 7 in a plane parallel to the rotating shaft 4 is equal in width to the projection of the tail of the rake root 8 in this plane.

[0022] The inside of the rake bar 3 has a rake bar middle water pipe 9, and the inside of the rotating shaft 4 has a rotating shaft middle water pipe 10; the rake bar middle water pipe and the rotating shaft middle water pipe are connected to each other, and the rotating shaft middle water pipe 10 is connected to an external pipeline for heating by inputting hot water materials.

[0023] The body casing 1 contains a semi-pipe heating pipeline 6, and steam is passed into the pipeline to provide a heat source for the material.

[0024] The material of the wall surface of the drying chamber inside the body shell 1 in contact with the material is stainless steel, which has good corrosion resistance and heat resistance.

Embodiment 2

[0026] The rake head 7 is an inverted L shape.

[0027] The projection of the rake head 7 in a plane parallel to the rotating shaft 4 is larger than the projection of the tail of the rake root 8 in this plane.

[0028] The inside of the rake bar 3 and the inside of the rotating shaft 4 have connected water pipes, which are connected with the external pipeline for inputting cold water to cool the material.

[0029] The body shell 1 contains a semi-pipe heating pipeline 6, and hot oil is passed into the pipeline to provide a heat source for the material.

[0030] The rake rod 3 is movably connected to the rotating shaft 4, and the rake rod 3 can swing 0-15° left and right along the axial direction of the rotating shaft 4, which further facilitates stirring and turning over materials.

[0031] The wall surface material of the drying chamber inside the body shell 1 that is in contact with the material is carbon steel, which has good corrosion resistance and heat resistance.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com