Micromachine thermopile infrared sensor with high duty cycle and manufacture method thereof

A technology of infrared detector and thermopile, which is applied in the direction of electric radiation detector, piezoelectric device/electrostrictive device, piezoelectric/electrostrictive/magnetostrictive device, etc. Effective improvement, small area and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

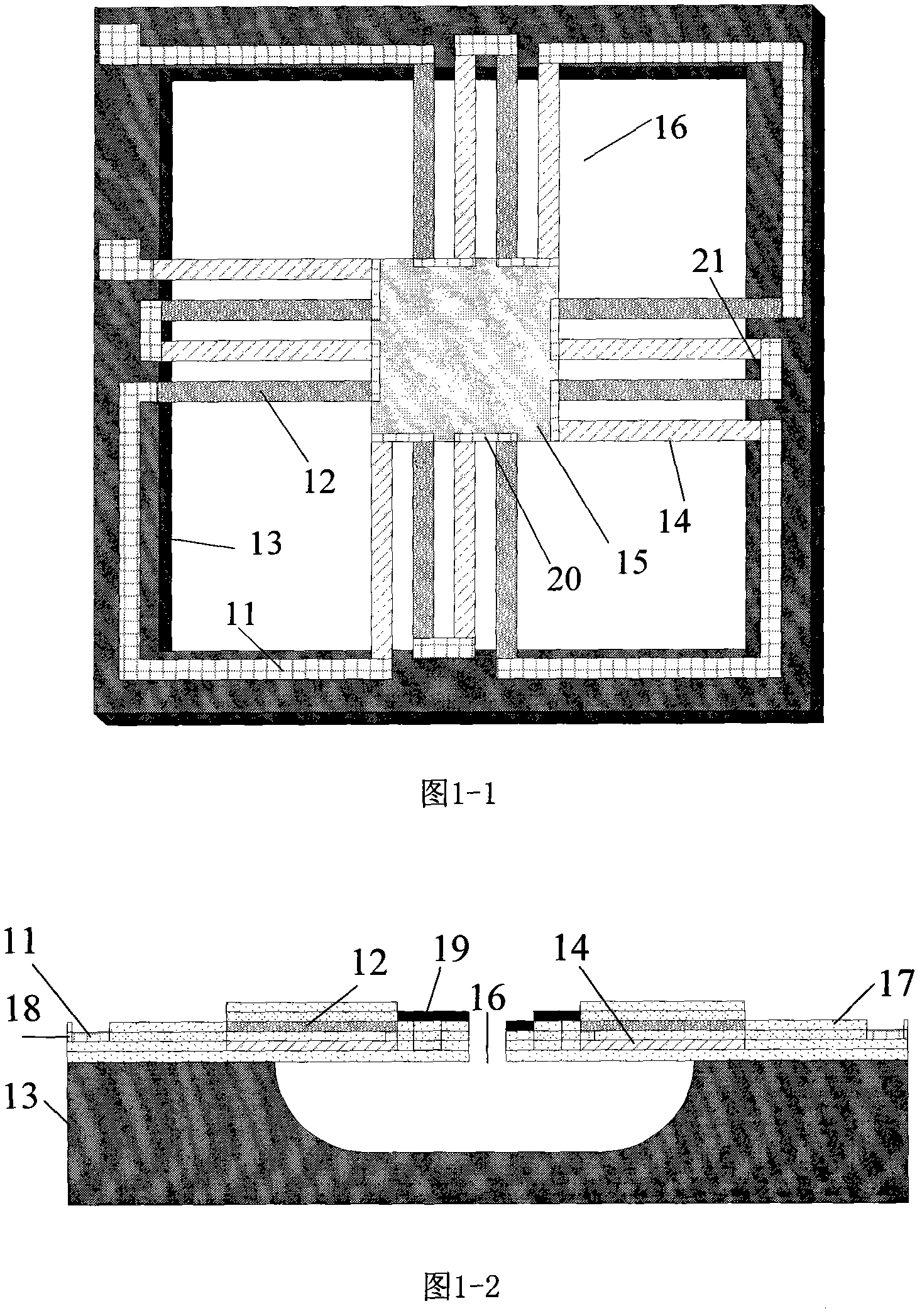

Embodiment 1

[0038] The thermocouple material is polysilicon and aluminum, and the heater material is polysilicon.

[0039] (1) Silicon oxide is thermally grown on the front surface of the polished silicon wafer (13), and then a layer of polysilicon (15) is deposited on the silicon oxide film by LPCVD.

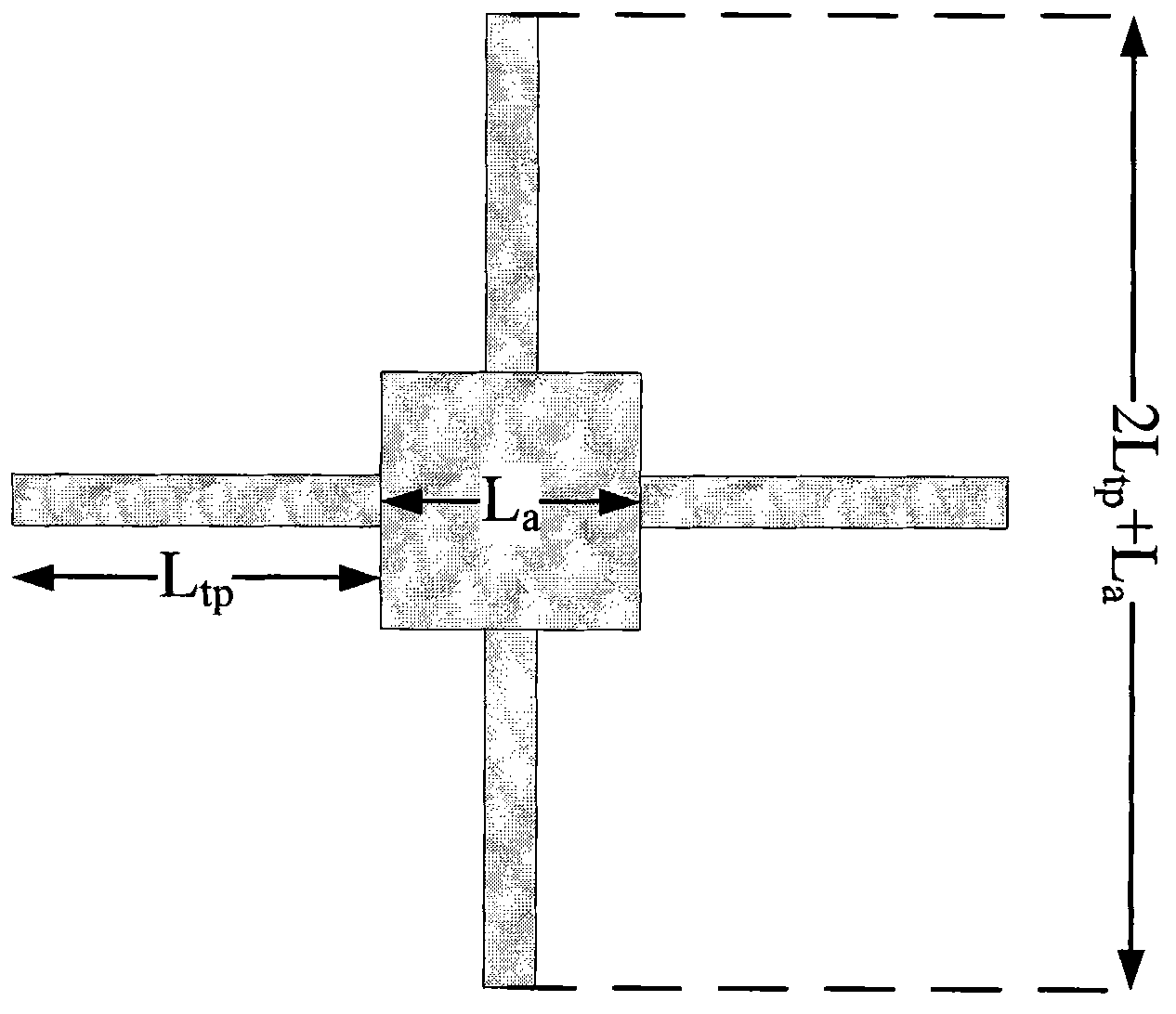

[0040] (2) Doping the polysilicon film to make it conductive. Photoetching patterns and etching to form polysilicon strips. The polysilicon (15) in the thermocouple area is used as a component of the thermocouple. The structure of the polysilicon thermocouple arm is as Image 6 As shown, the thermocouple arm is folded.

[0041] (3) Use LPCVD or PECVD to deposit a layer of silicon oxide (18) as an insulating layer. Photoetch the lead hole pattern to remove the silicon oxide in the lead hole area. see Figure 7-1 .

[0042] (4) Deposit a layer of metal thin film aluminum by evaporator or sputtering apparatus. The metal lines are lithographically etched and the metal is corroded. Part of the metal...

Embodiment 2

[0047] The specific implementation steps are partly the same as those in Embodiment 1, and the main difference is: First, the channel process released by the thermopile structure in step (6) of Embodiment 1 is removed. Second, the silicon substrate is completely radiated from the back side to release the thermopile structure. Third, a layer of black body material for enhancing infrared absorption is deposited in the thermopile absorption area. The device geometry is such as Figure 8 Shown.

Embodiment 3

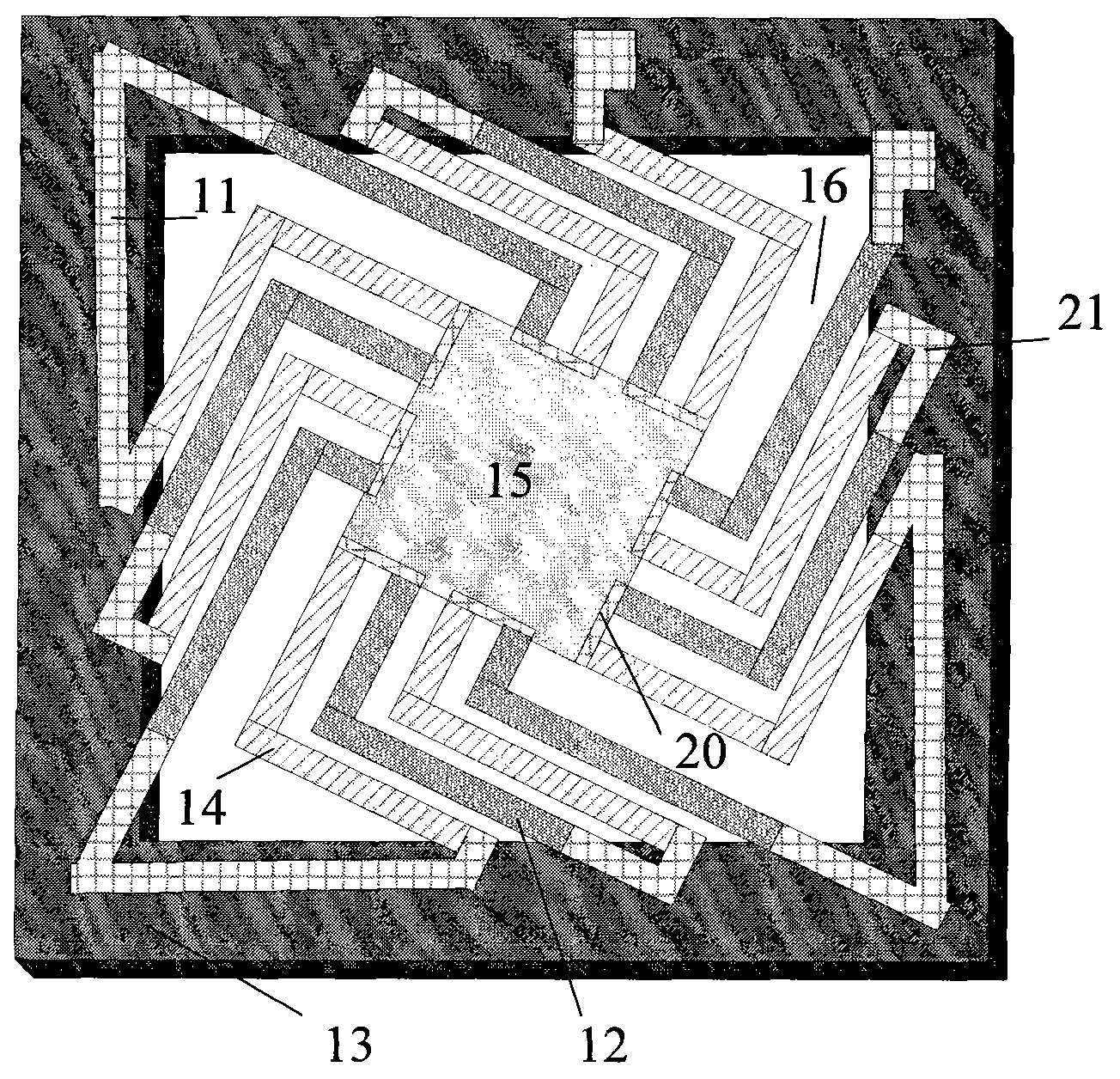

[0049] The specific implementation steps are partly the same as those in Embodiment 1, the main difference is that the folding of the thermocouple structure is changed from two folding to three equal-length folding, thereby further improving the duty cycle. The layout structure of the thermopile device is as follows Picture 9 Shown.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap