Non-refrigerant thermopile infrared detector and manufacturing method thereof

A technology for infrared detectors and manufacturing methods, applied in electric radiation detectors, piezoelectric/electrostrictive/magnetostrictive devices, piezoelectric effect/electrostrictive or magnetostrictive motors, etc., can solve problems that cannot be monitored , low device test efficiency, and the inability to reduce device costs, etc., to achieve the effects of reducing test costs, simplifying test steps, and improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

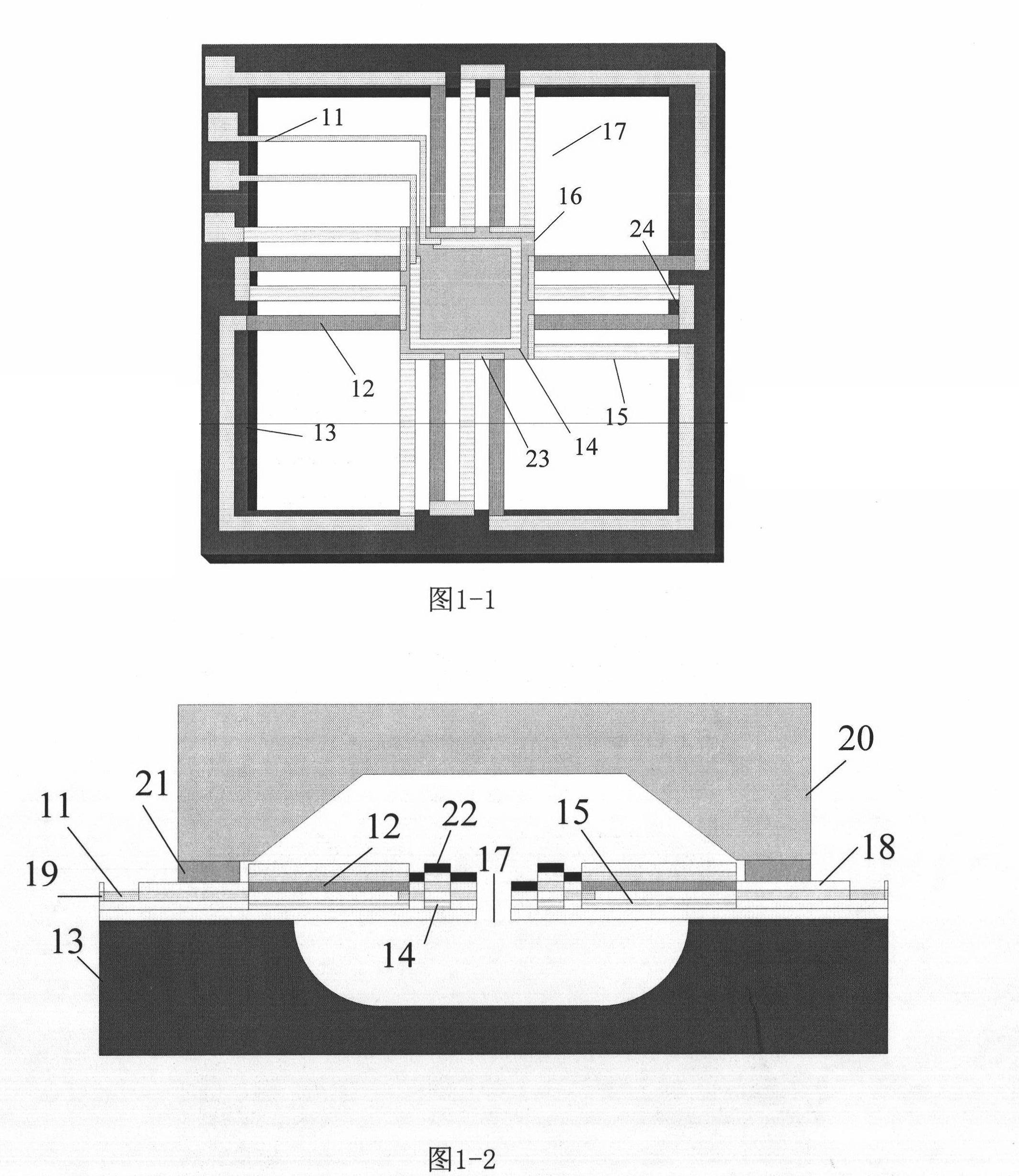

Embodiment 1

[0055] The material of the thermocouple is polysilicon and aluminum, and the material of the micro heater is polysilicon.

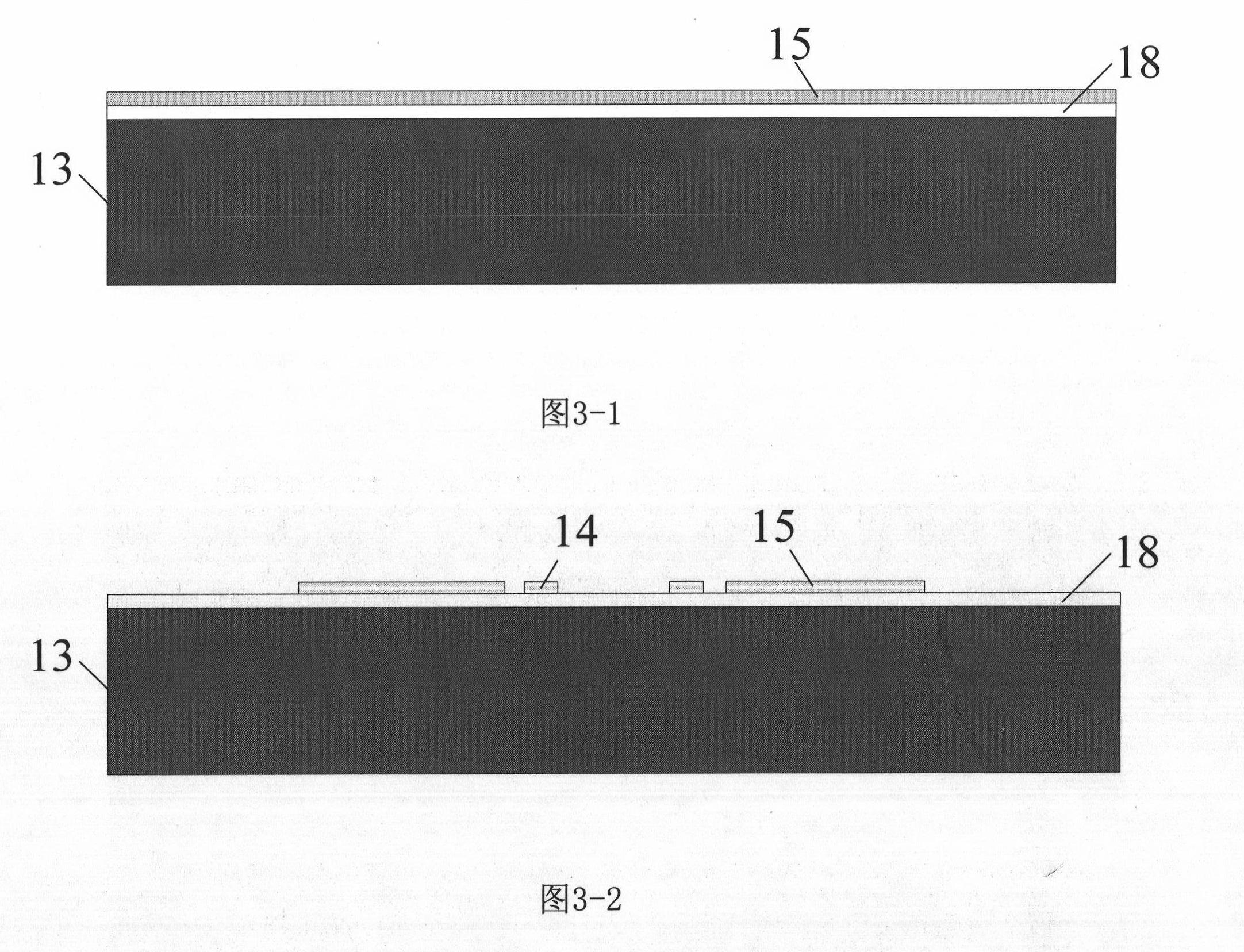

[0056] (1) Thermally grow silicon oxide 18 on the front side of the polished silicon wafer 13, and then deposit a layer of polysilicon 15 on the silicon oxide film by LPCVD. See Figure 3-1 .

[0057] (2) Doping the polysilicon film to make it conductive. Photolithographic patterning, etching to form polysilicon strips, the polysilicon 15 in the thermocouple area is used as a component of the thermocouple, and the polysilicon in the absorption area is used as a component 14 of the micro heater. See Figure 3-2 .

[0058] (3) A layer of silicon oxide 18 is deposited as an insulating layer by LPCVD or PECVD. Photoetching the lead hole pattern to remove the silicon oxide in the lead hole area. See Figure 3-3 .

[0059] (4) Deposit a layer of metal thin film aluminum by evaporation or sputtering. Photoetching metal lines, corroding metal, part of th...

Embodiment 2

[0067] The material of the thermocouple is polysilicon and aluminum, and the material of the heater is metal film.

[0068] (1) Thermally grow silicon oxide 18 on the front side of the polished silicon wafer 13, and then deposit a layer of polysilicon 15 on the silicon oxide film by LPCVD.

[0069] (2) Doping the polysilicon film to make it conductive. Photolithographic patterning, etching to form polysilicon strips, and polysilicon 15 in the thermocouple area as a component of the thermocouple.

[0070] (3) A layer of silicon oxide 18 is deposited as an insulating layer by LPCVD or PECVD. Photoetching the lead hole pattern to remove the silicon oxide in the lead hole area.

[0071] (4) Deposit a layer of metal thin film by evaporator or sputtering device. Photoetching metal lines, corroding metal, part of the metal lines 12 and the polysilicon lines in step 2 form a thermocouple pair structure, part of the metal lines 11 are used as metal wiring to realize the electrical c...

Embodiment 3

[0079] The specific implementation steps are the same as in Example 1, the main difference is: first, the polysilicon strips at the thermocouples in Step 2 of Example 1 are changed from being parallel to each side of the absorption region to being arranged at equal intervals along the radial direction of the absorption region. Second, the polysilicon heaters at the absorption region in Step 2 of Example 1 are changed to a circular arrangement, and the rest remain unchanged. The device geometry is as Figure 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com