Gas leakage detection apparatus

A gas leak detection and gas technology, which is used in liquid/vacuum measurement for liquid tightness, and by measuring the acceleration and deceleration rate of fluid, etc., to achieve the effect of protecting personal safety, wide application range and high sampling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

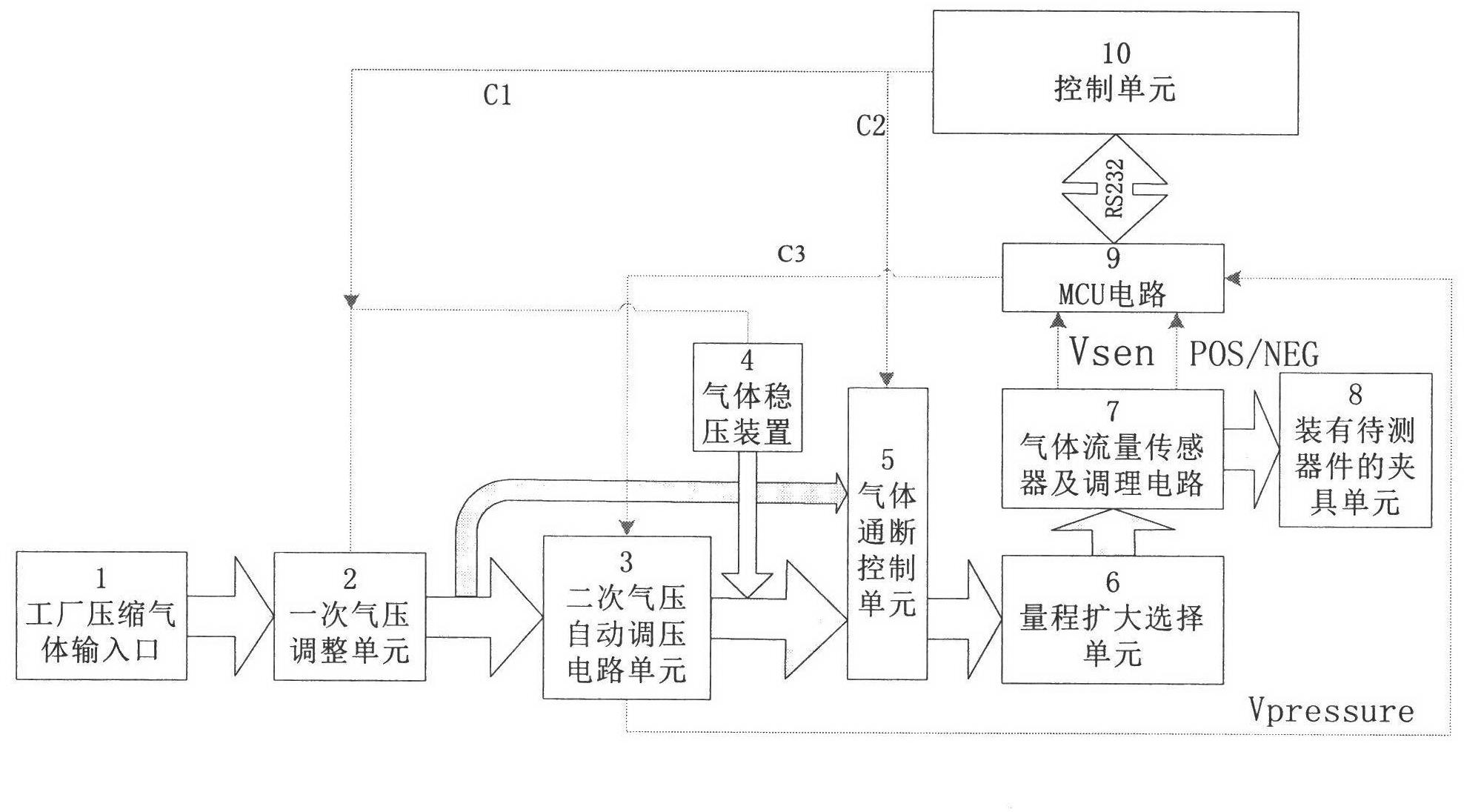

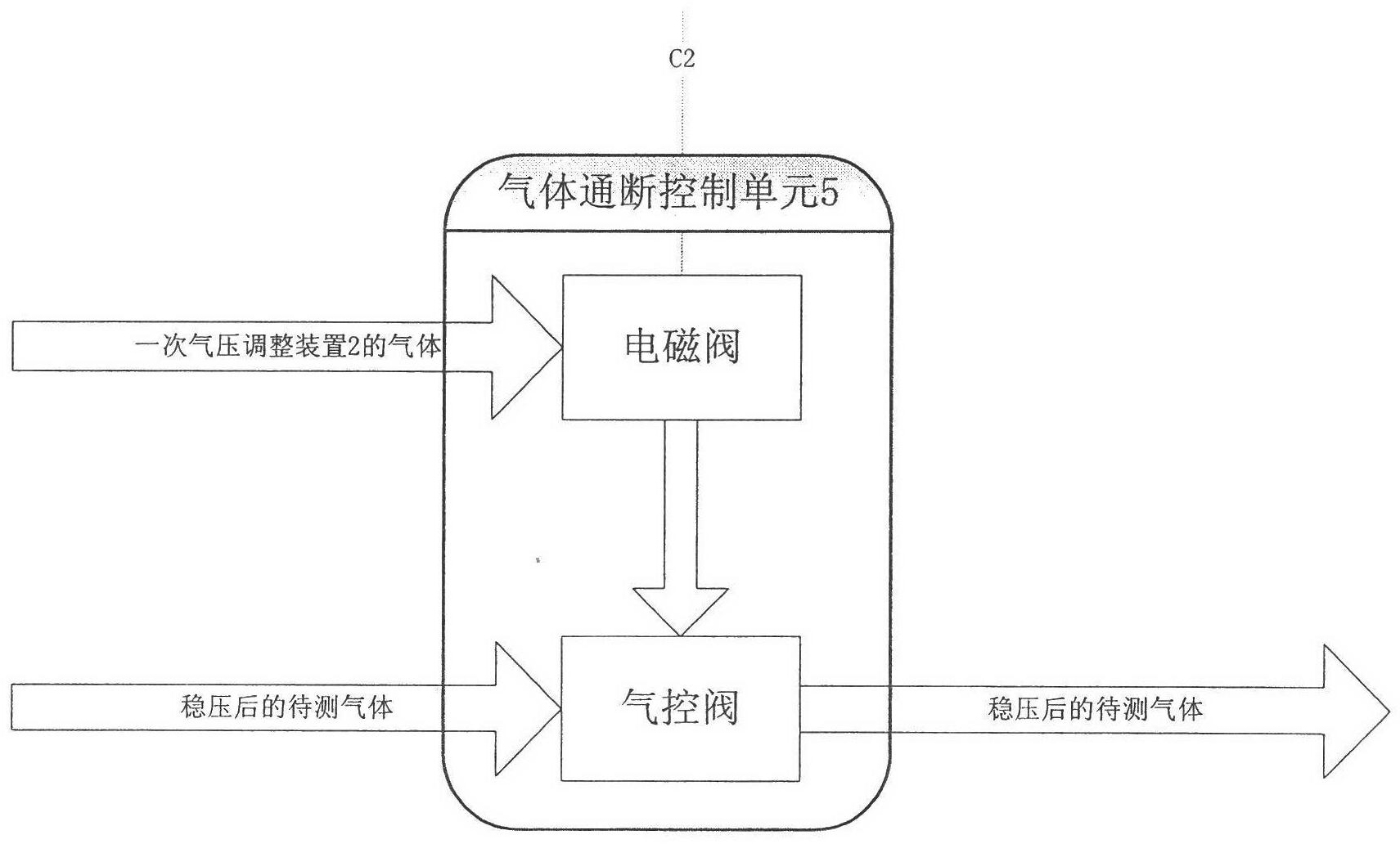

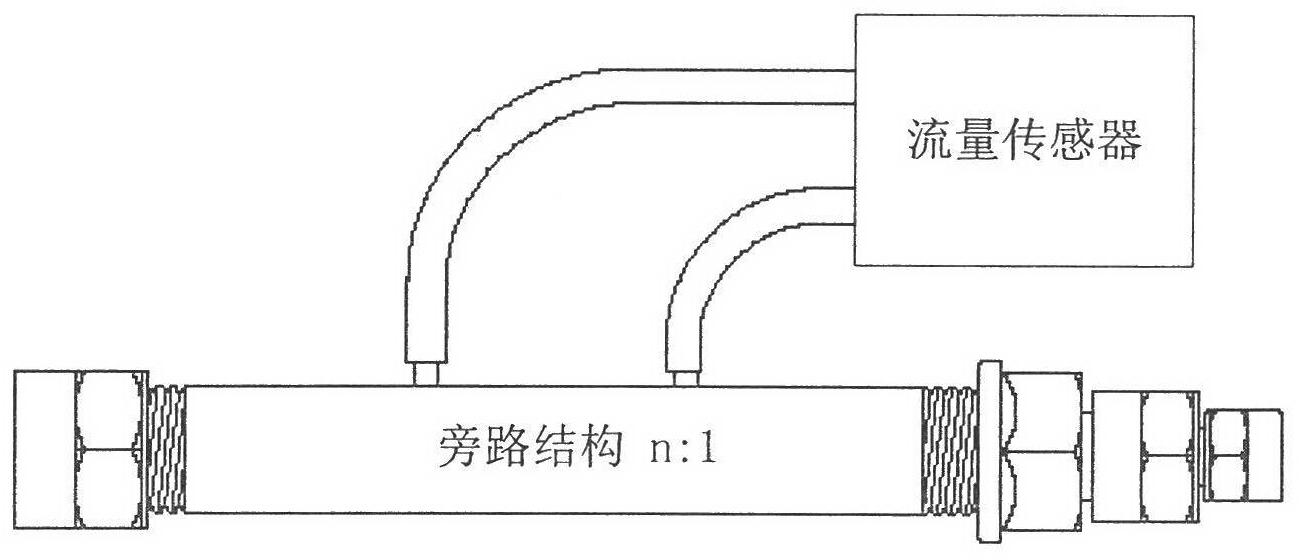

[0032] Hereinafter, specific embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0033] figure 1 It is a schematic diagram of the overall structure of the gas leakage device according to the present invention. Such as figure 1 As shown, the gas leakage device according to the present invention includes a factory compressed gas input port 1, a primary air pressure adjustment unit 2, a secondary air pressure adjustment unit 3, a gas stabilizing device 4, a gas on-off control unit 5, a range expansion selection unit 6, Gas flow sensor and conditioning circuit 7 , clamp unit 8 , MCU (micro control module) circuit 9 , and control unit 10 .

[0034] The object to be tested in this embodiment is a circular film-shaped object to be tested. It is necessary to test the airtightness of this product, that is, to detect gas leakage, and to judge whether it is qualified or not through the detection of gas flow. The object to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com