Geotechnical thermal response testing method

A technology of thermal response testing and rock soil, applied in the field of thermal response testing, can solve problems such as inaccuracy, large error, and inability to obtain thermal and physical parameters, and achieve the effect of reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

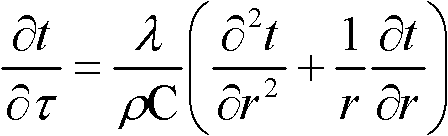

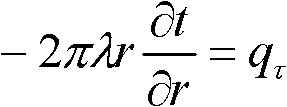

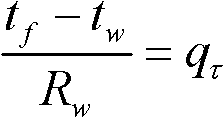

Method used

Image

Examples

Embodiment Construction

[0021] The following are specific examples of the present invention, but the present invention is not limited to these examples.

[0022] The thermal response testing device used in this geotechnical thermal response test method includes a liquid circulation loop connected in turn by a water pump, a heater, and an underground pipe. There is also a flow sensor on the circuit, and the heater is a heater with adjustable heating power, and a power sensor is arranged in the heater. The thermal response test device also includes an acquisition control system, a heater, a power sensor, a temperature sensor and a flow rate sensor. The sensors are all connected with the acquisition control system, and the acquisition control system can collect the data of each sensor and control the heater for heating.

[0023] The thermal response test method of the rock and soil is as follows: the actual temperature value of the buried pipe is tested by the temperature sensor, and there are two tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com