Energy factor based ultrasonic guided wave detection method of debonding defect of bonding structure

A technology of ultrasonic guided wave and energy factor, which is applied in the direction of analyzing solids using sound wave/ultrasonic wave/infrasonic wave, which can solve the problems of low detection efficiency and inability to detect, and achieve fast detection speed, sensitive change of target characteristic value, and high detection efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

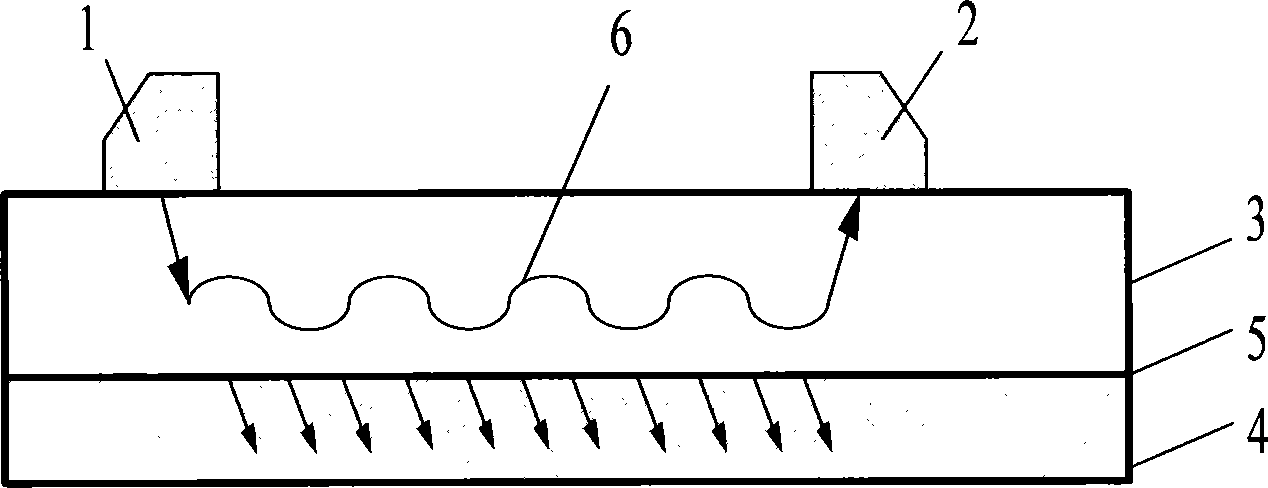

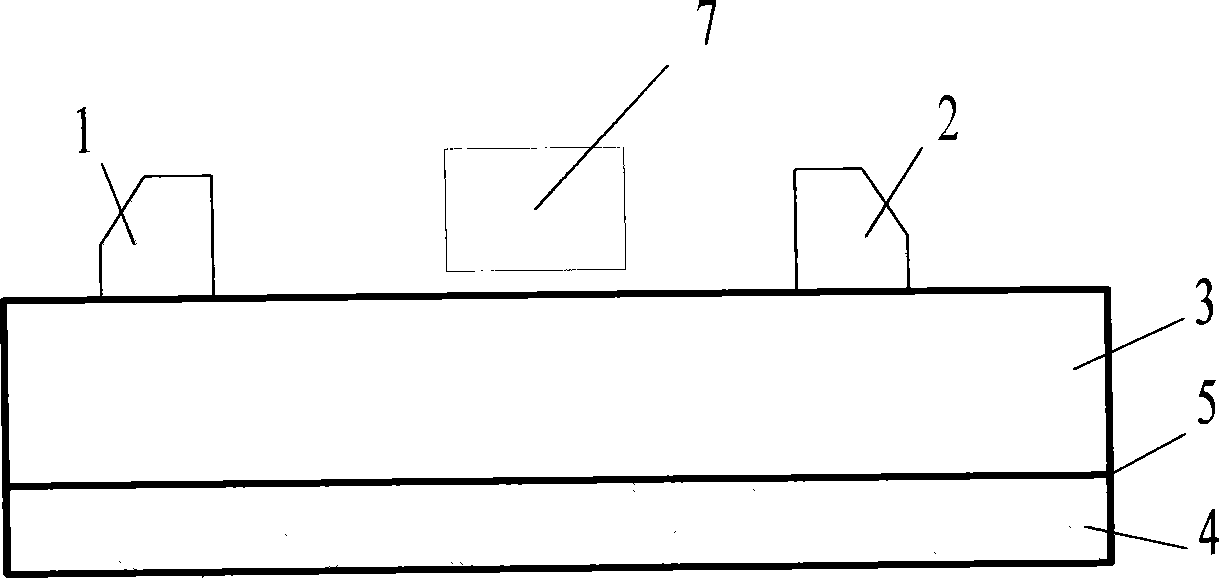

[0032] Such as figure 1 As shown, the sample to be tested in this embodiment is a bonded structure of glass fiber composite material plate and rubber, the size is 200mm×200mm, the upper medium is a composite material plate with a thickness of 5mm, and the lower medium is rubber with a thickness of 3mm. A circular debonding defect with a diameter of 30 mm was artificially prefabricated between the composite material and the rubber in the middle area of the structure.

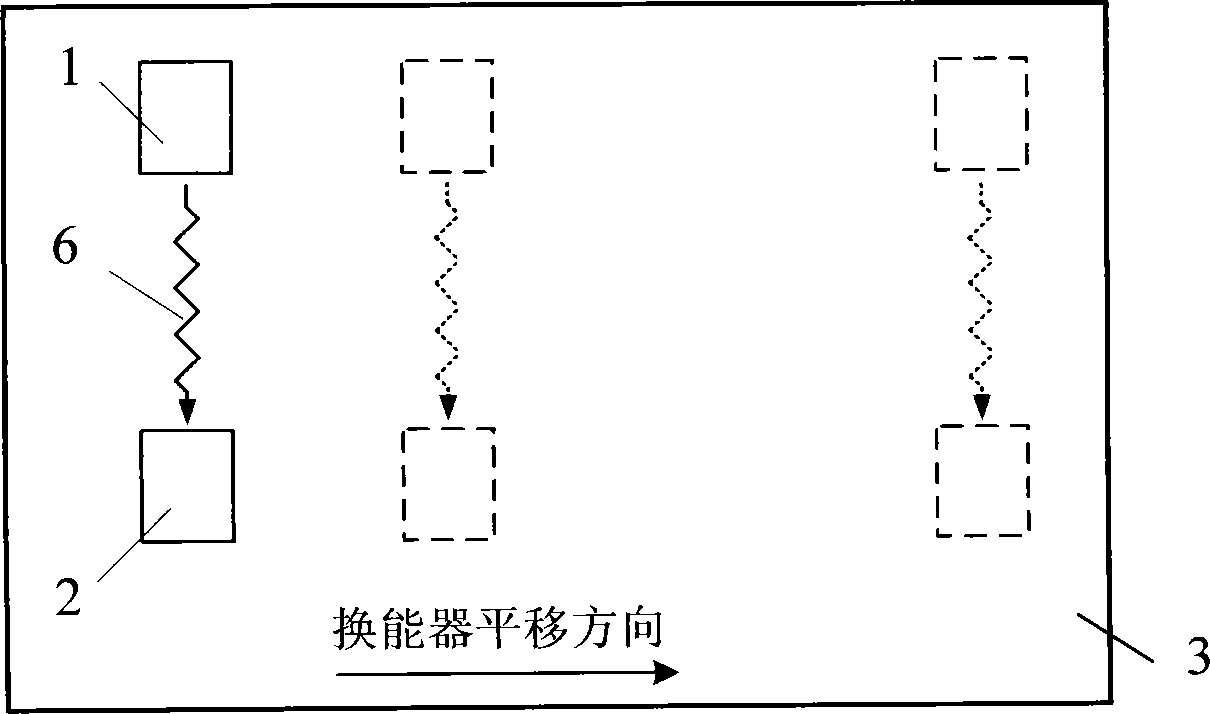

[0033] Step 1: Place two ultrasonic transducers with variable angles for transmitting and receiving on the composite material board, and the center frequency of the transducer is 0.5MHz; select the ultrasonic guided wave in the composite material board as S0 mode, and refer to the composite material board According to the dispersion curve, the velocity of the ultrasonic guided wave in this mode is about 4800m / s; the velocity of the longitudinal wave of the ultrasonic wave in the transducer is about 2700m / s; acc...

Embodiment 2

[0037] The above samples were compared for detection:

[0038] The sample was detected by the pulse echo detection method, the interface echo amplitude of the well-bonded area was 0.79, the interface echo amplitude of the debonding area was 1.1, and the target characteristic value of the debonding area (ie, the echo amplitude ) is 39.2% relative to the well-bonded area. However, with the method of the present invention, the change of the energy factor of the ultrasonic guided wave in the debonded area relative to the well-adhesive area is 49.3%. It can be seen that the method of the present invention is more sensitive to the change of the target eigenvalue than the pulse echo method, and it is easier to find the debonding defect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com