Automatic detection device for motor

An automatic detection device and self-inspection technology, applied in the field of mechatronics, can solve problems such as lack of scientificity, and achieve the effect of simple and reliable installation, simple design and manufacturing, and reliable adhesive position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

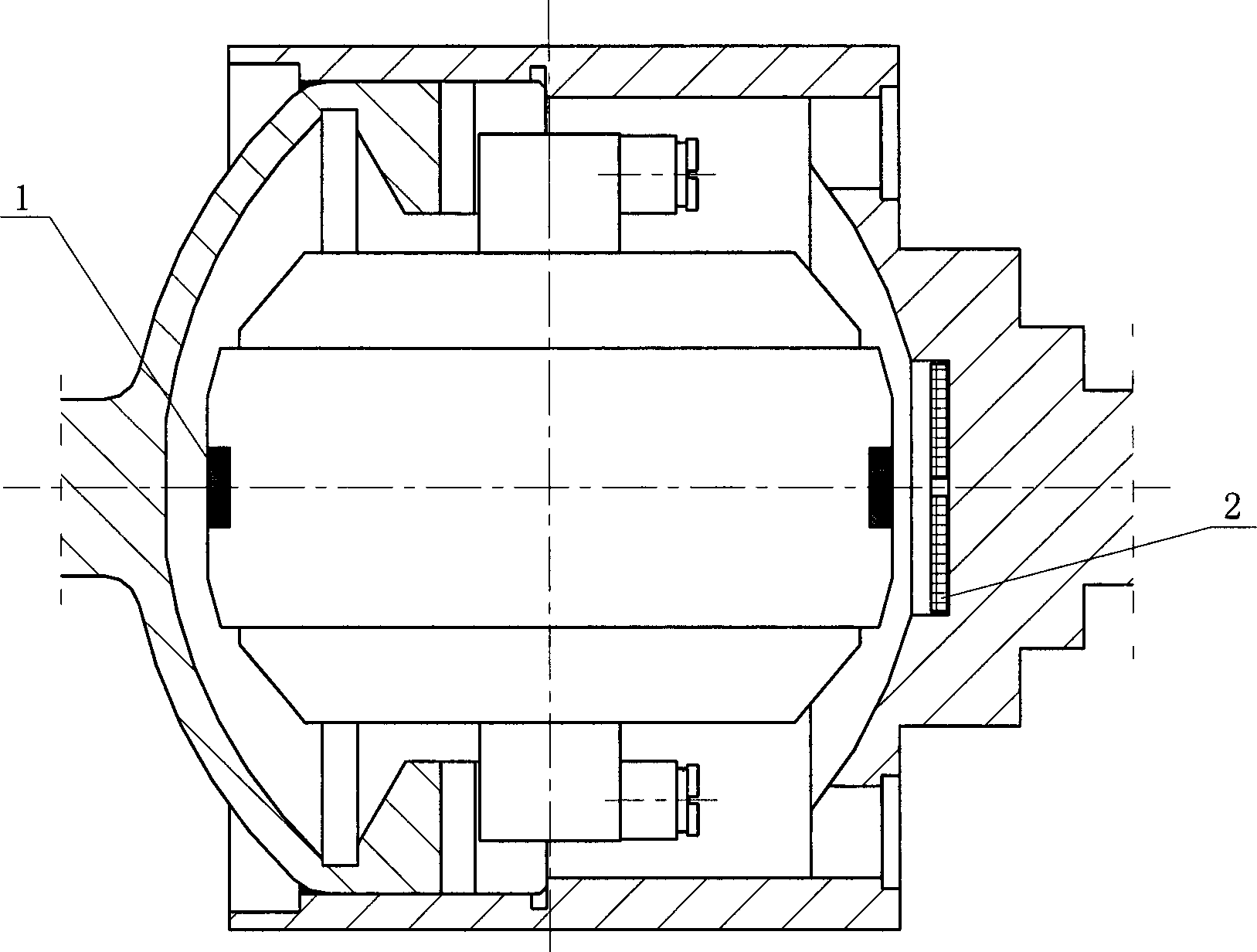

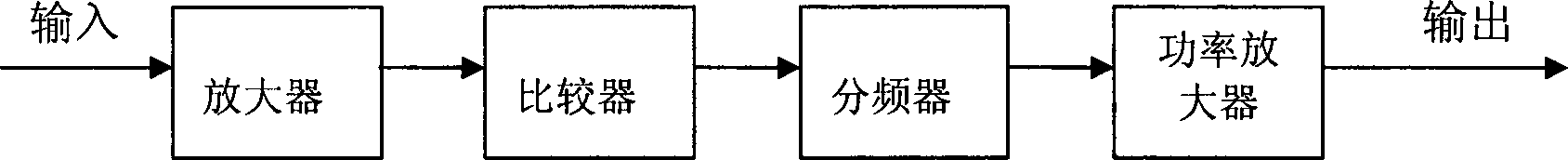

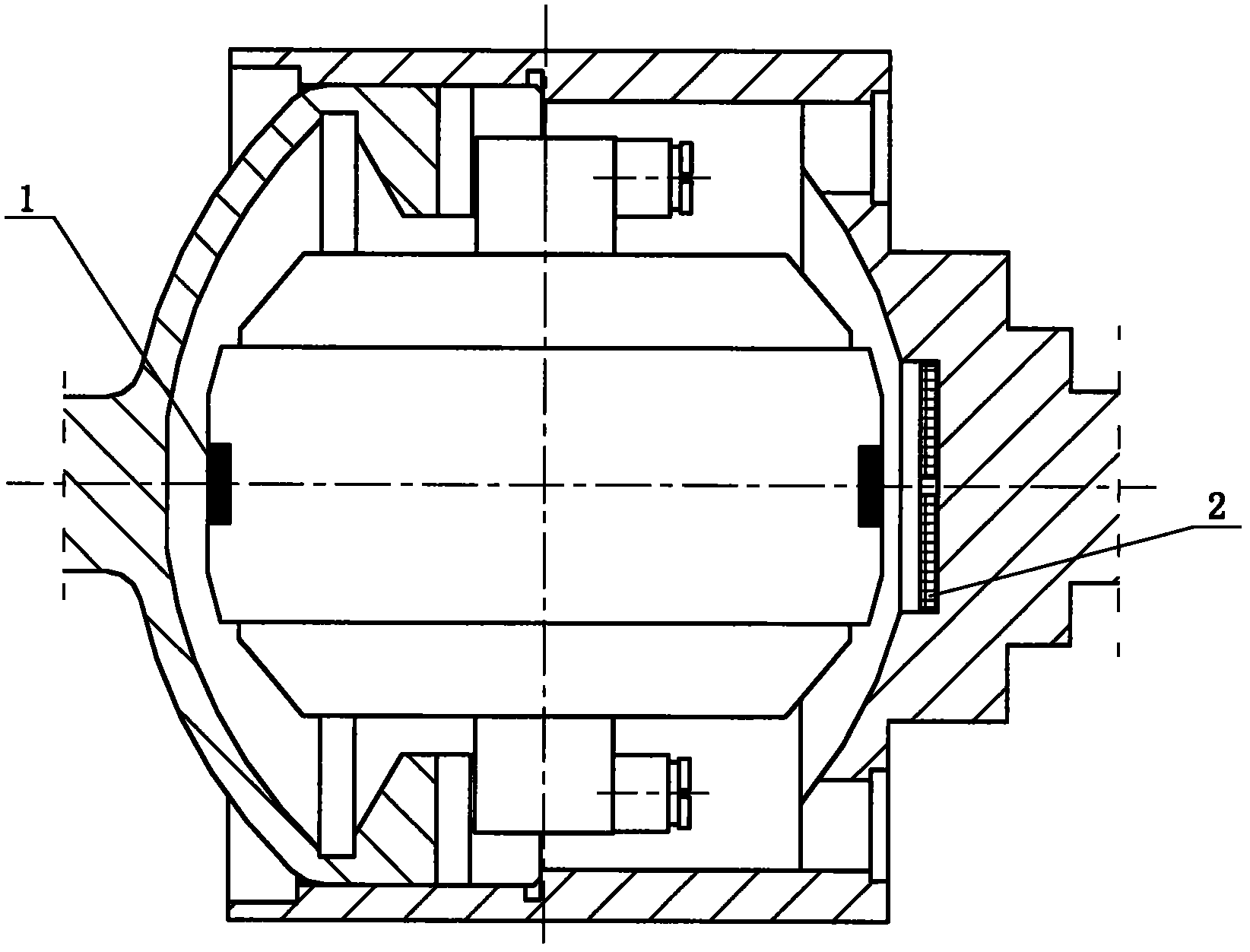

[0015] like figure 1 As shown, the motor self-inspection device is composed of a motor self-inspection magnet 1, a self-inspection coil 2 and a self-inspection shaping circuit. The motor is located in the inner cavity of the float assembly composed of the instrument float housing and the float cover. The self-inspection magnet 1 is embedded in the outer circumference of the rotor body of the motor, and the self-inspection coil 2 is installed on the axial end surface of the inner cavity of the float assembly. Above, the self-test shaping circuit is included in the supporting electronic box. When the motor rotates at high speed, the self-inspection magnet 1 rotates together with the motor rotor, and an induced potential is generated on the corresponding self-inspection coil 2, forming a periodic AC signal similar to a sine wave, which is sent to the self-inspection shaping circuit , and then output a square wave signal with a certain frequency and amplitude after amplification,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com