High-strength elongation steel sheet, method for manufacturing hot-rolled steel sheet, cold-rolled steel sheet, zinc-coated steel sheet, and alloyed zinc-coated steel sheet

A technology for cold-rolled steel sheets and hot-rolled steel sheets is applied in the fields of high-strength elongation steel sheets and the preparation of hot-rolled steel sheets, cold-rolled steel sheets, zinc-coated steel sheets and alloy zinc-coated steel sheets, and can solve the problems of long phase transformation time and manufacturing costs. High, unavailability of hot rolling or annealing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] According to the production method of a hot-rolled steel sheet according to the present invention, a steel ingot is reheated by a conventional method to perform hot rolling.

[0053] In the case of hot-rolled steel sheets, hot rolling is performed at a temperature above Ar3, and coiling is performed in the range from Ms (temperature at which martensitic transformation starts) to 450°C.

[0054] The hot rolling completion temperature is limited above the Ar3 transformation point to prevent the steel sheet from being rolled in the two-phase region. When hot rolling is performed below the Ar3 transformation point, the steel sheet is rolled in two phase regions, and thus may cause an uneven grain structure. Therefore, it is preferable that the completion temperature of hot rolling be limited to the Ar3 transformation point or higher.

[0055] In addition, when the coiling temperature is lower than Ms, it is difficult to obtain the structure of bainite and retained austenit...

Embodiment

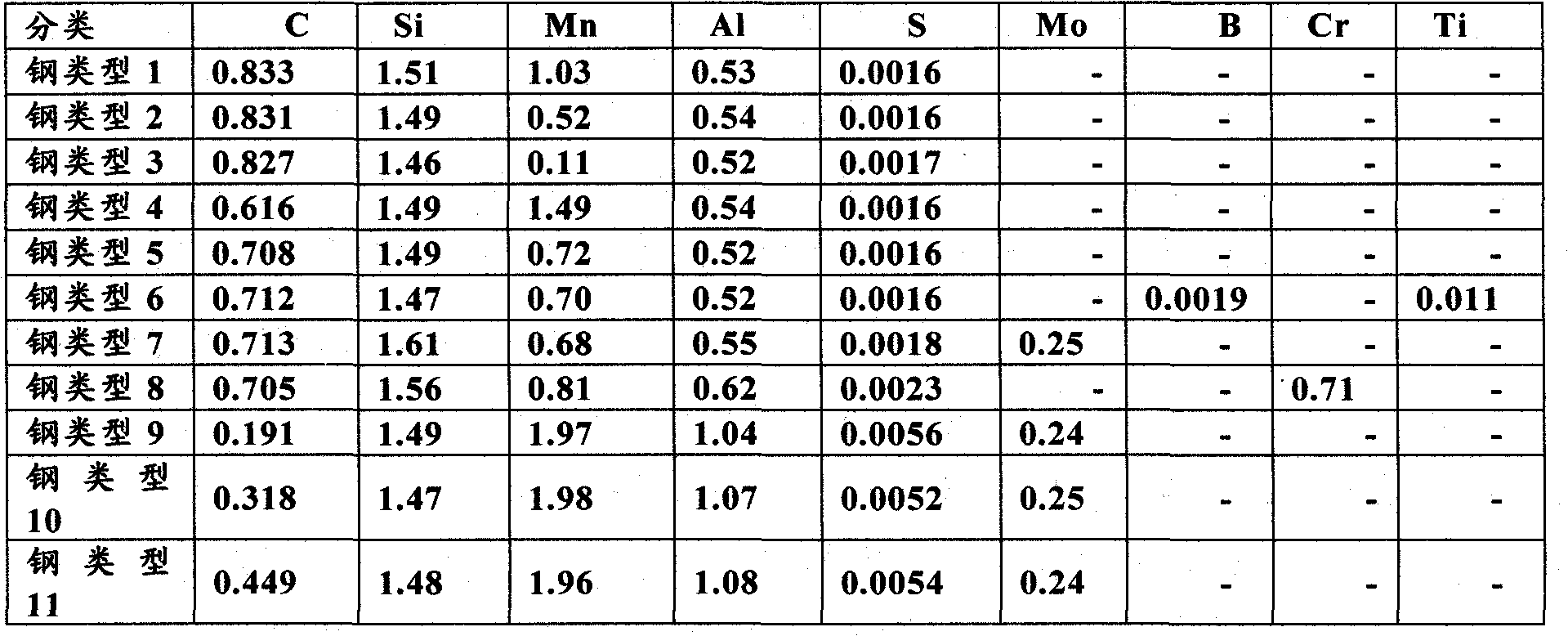

[0063] A steel slab having a thickness of 90 mm and a width of 175 mm having a component system shown in Table 1 below was prepared, reheated at 1200° C. for 1 hour, and then hot-rolled to have a hot-rolled thickness of 3 mm. Some billets were used as samples of hot-rolled steel sheets, and other billets—as samples of cold-rolled steel sheets—were cold-rolled followed by annealing heat treatment.

[0064] The hot-rolling completion temperature of the samples used for hot-rolling steel sheets was set above the Ar3 transformation point, and the samples were placed in a furnace preheated to 400°C after cooling, maintained for 1 hour, and hot-rolled after furnace cooling coiled.

[0065] In contrast, samples for cold-rolled steel sheets—shown in Table 3 below—were placed in a furnace preheated to 600°C for 1 hour, and were subjected to hot coiling with furnace cooling, and the hot-rolled sheets were again subjected to 60 % cold rolled to achieve a thickness of 1.2mm, annealed at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com