Anti-overflow cooking boiler

A cooking pot and anti-overflow technology, applied in the fields of application, food preparation, food science, etc., can solve problems that affect the service life of coal stoves, affect the air, pollute food, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing, the present invention will be further described:

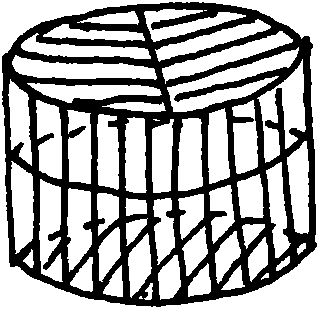

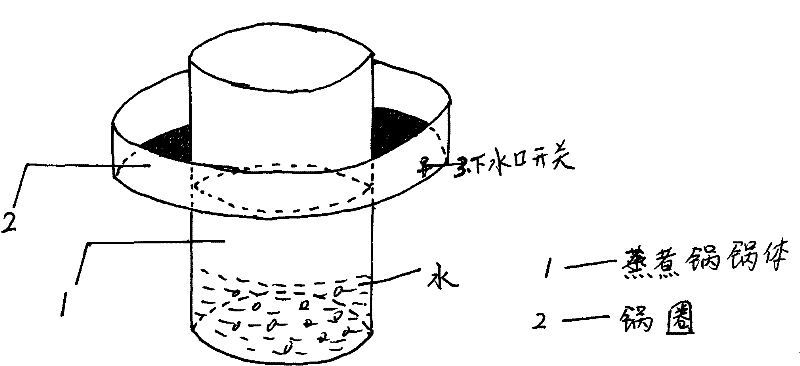

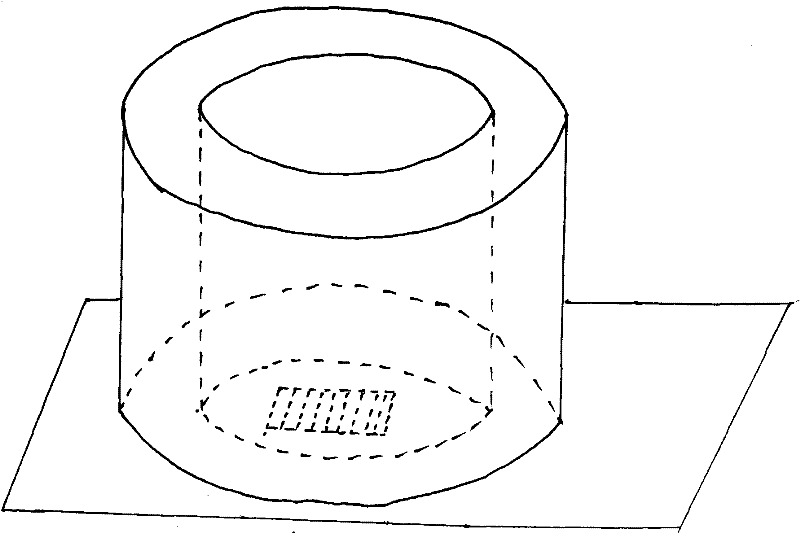

[0010] The present invention is achieved in that the independent cooking fence cage (3) is a hollow hollow cylinder, which can smoothly enter and exit the pot body (1), and the materials that need to be cooked are contained in the cooking fence cage (3). Coal furnace (4) hearth is a hollow cylinder, and the hearth diameter is slightly larger than the pot body diameter. When in use, the bottom of the coal stove is burning coal, and the entire cooking pot is placed above the burning coal. Put an appropriate amount of water in the cooking pot, and cook the cooking grid cage with the materials in the cooking pot. After boiling, the overflowing liquid flows along the mouth of the pot. It flows into the ring, and after saving, it plays a role of water bath heat preservation and heating for the entire cooking system, saving energy. After the production is stopped, the overflowin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com