Traction orientating mechanism of wire drawing machine

A technology of orientation mechanism and wire drawing machine, which is applied in the field of metal product production, can solve the problems of broken wire piles, low production efficiency, unguaranteed product quality, etc., and achieves the effect of balanced tension and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific drawings and embodiments.

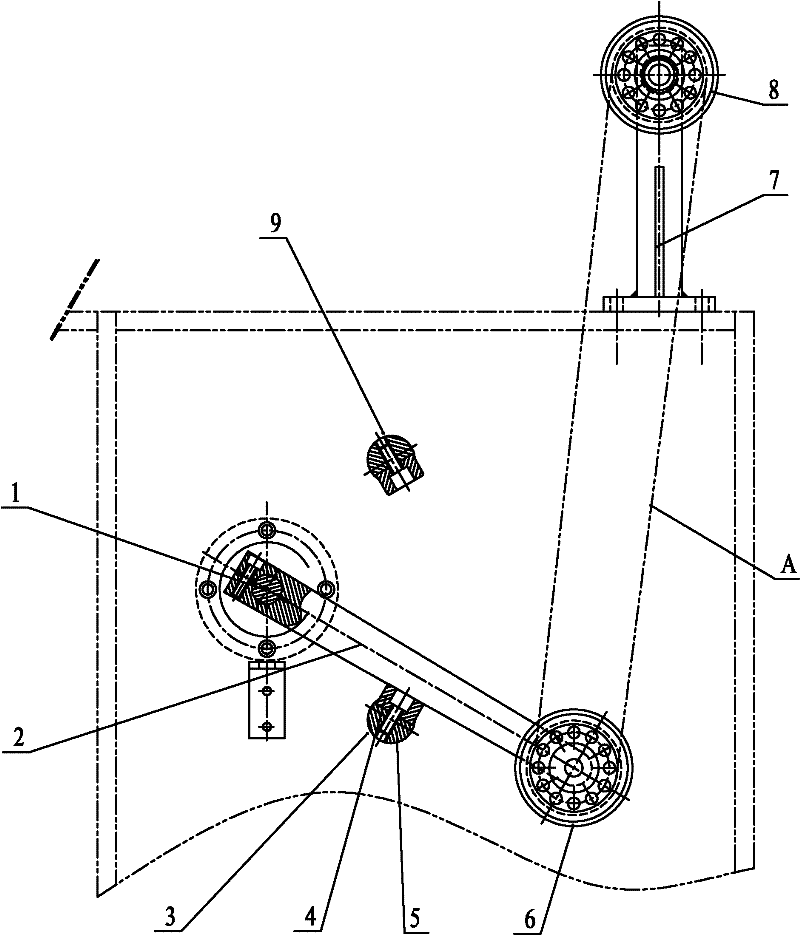

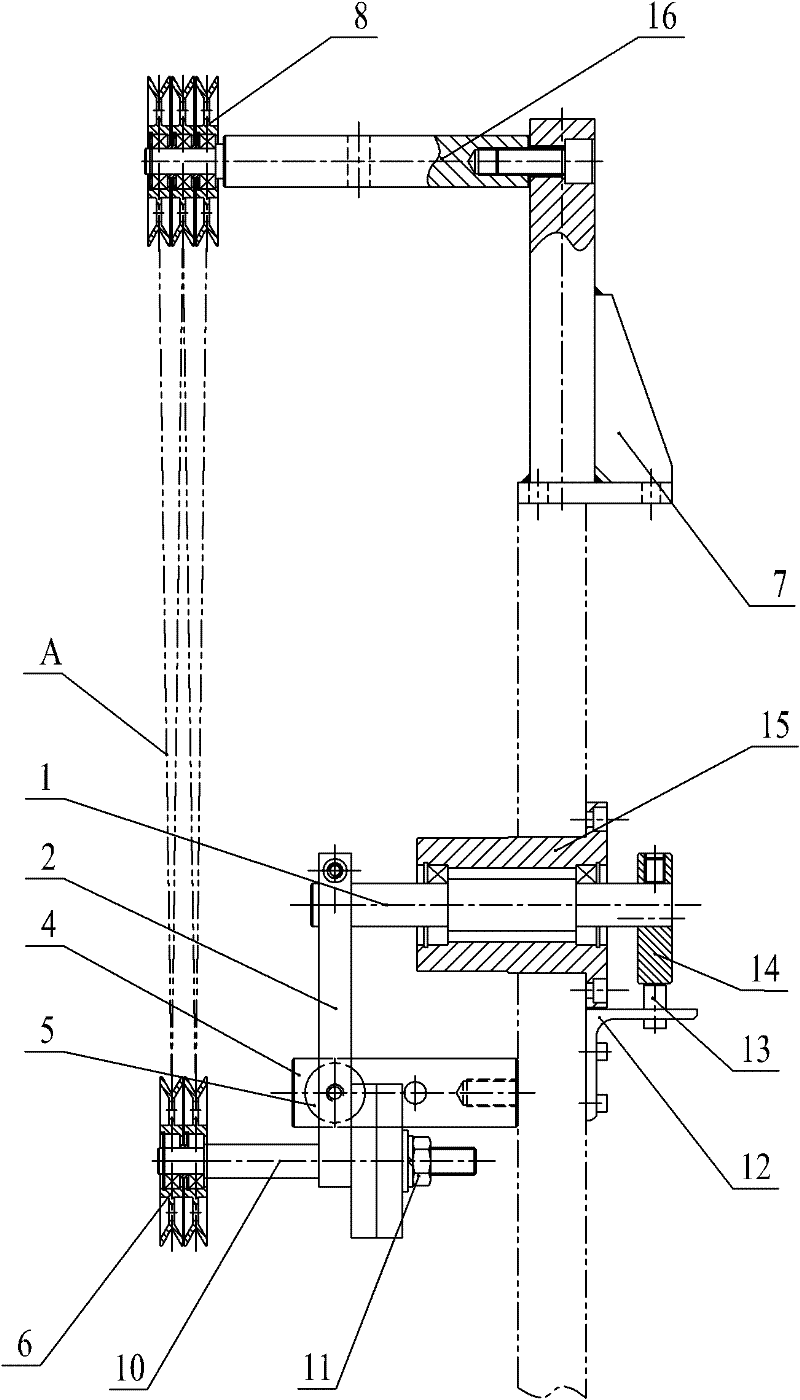

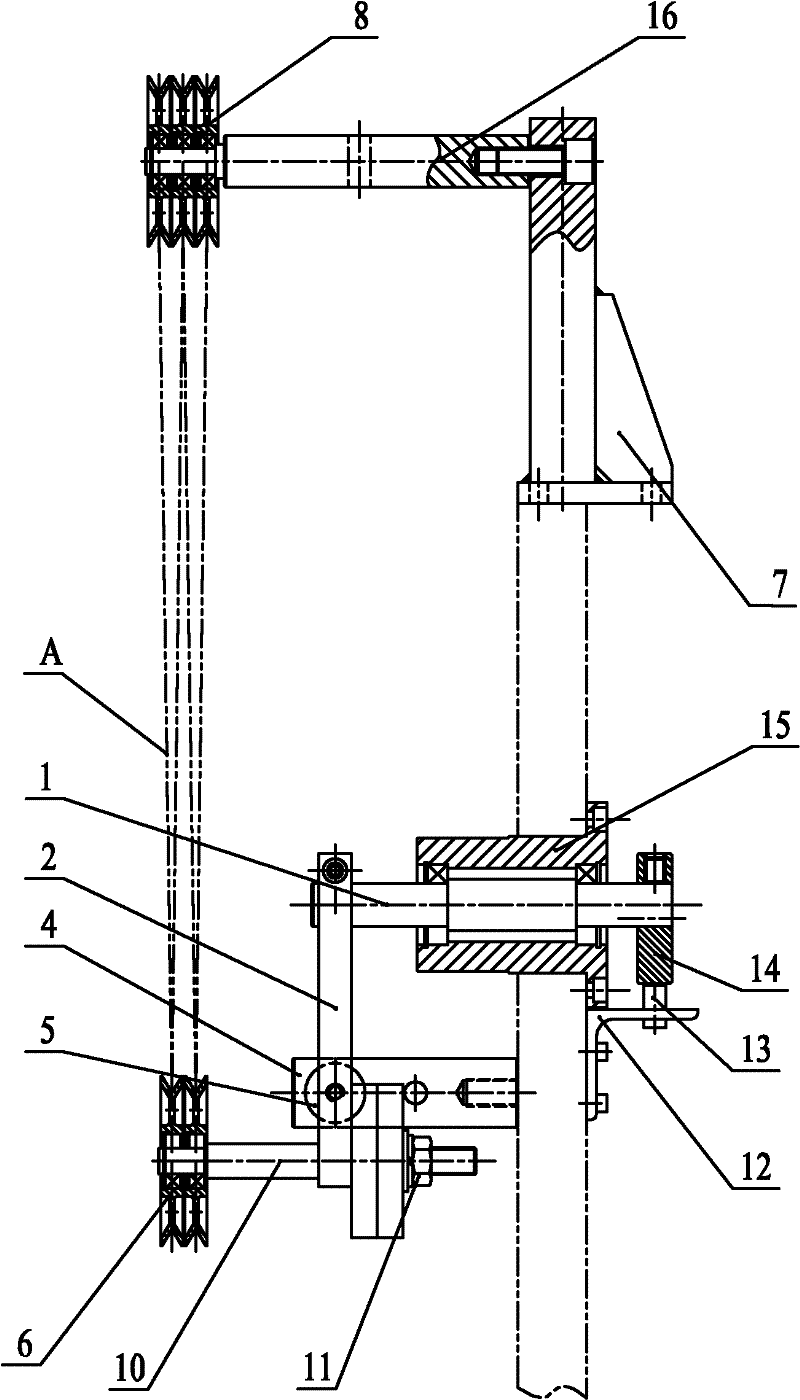

[0015] The traction and orientation mechanism is used to ensure the tension balance of the steel wire A during the drawing and winding process, so as to achieve the synchronous operation of the host machine and the wire take-up machine; at the same time, it ensures that the steel wire A will not be broken or messed up during the winding process.

[0016] As shown in the figure, the traction orientation mechanism is mainly composed of a rotating arm shaft 1, a connecting rod 2, a buffer rod 4, a buffer pad 5, a moving wheel 6, a bracket 7, a fixed wheel 8, a roller shaft 10, a nut 11, an induction bracket 12, Parts such as sensor 13, induction cam 14, bearing block 15 and fixed shaft 16 are formed.

[0017] Such as figure 1 , figure 2 As shown, the bearing seat 15 is fixed on the box body of the wire drawing machine by screws, and the rotating arm shaft 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com