Rubber coating structure of mechanical components

A technology of mechanical parts and encapsulation structure, applied in the field of mechanical parts, can solve the problems of falling off, insufficient adhesion, user injury, etc., and achieve the effect of stable adhesion, tight bonding, and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment

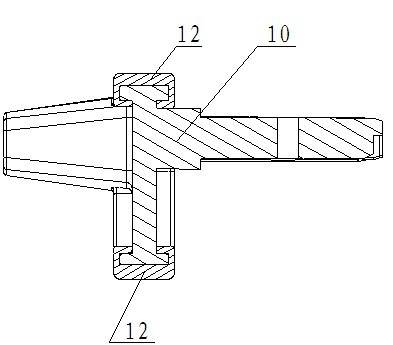

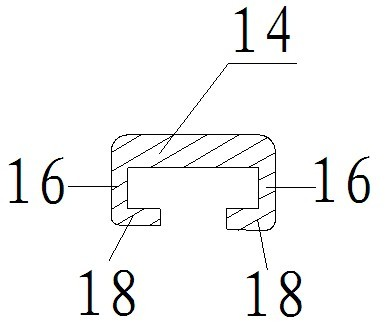

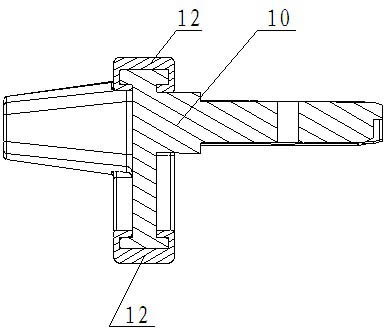

[0014] see figure 1 As shown, a rubber-covered structure of mechanical parts, figure 1 The mechanical part shown in is the side pipe plug used on the automobile shade, and the surface of the side pipe plug is provided with a covering layer 12, and the covering layer 12 extends from the upper surface of the side pipe plug to the upper surface On the opposite lower surface, the area of the rubber coating layer 12 can make it adhere to the surface of the side pipe plug in an encircling manner, preferably the area of the rubber coating layer 12 accounts for at least 1 / 2 of the surface area of the mechanical parts, see figure 2 As shown, the longitudinal section of the rubber coating layer 12 is dovetail-shaped, including a horizontal side 14 and two vertical sides 16 integrally connected with the horizontal side 14, and the free ends of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap