Light-duty routing inspection trolley for high speed railway

A high-speed railway, light-duty technology, applied in the direction of railway inspection vehicles, etc., can solve the problem of long railway time, and achieve the effects of simple structure, saving inspection time, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

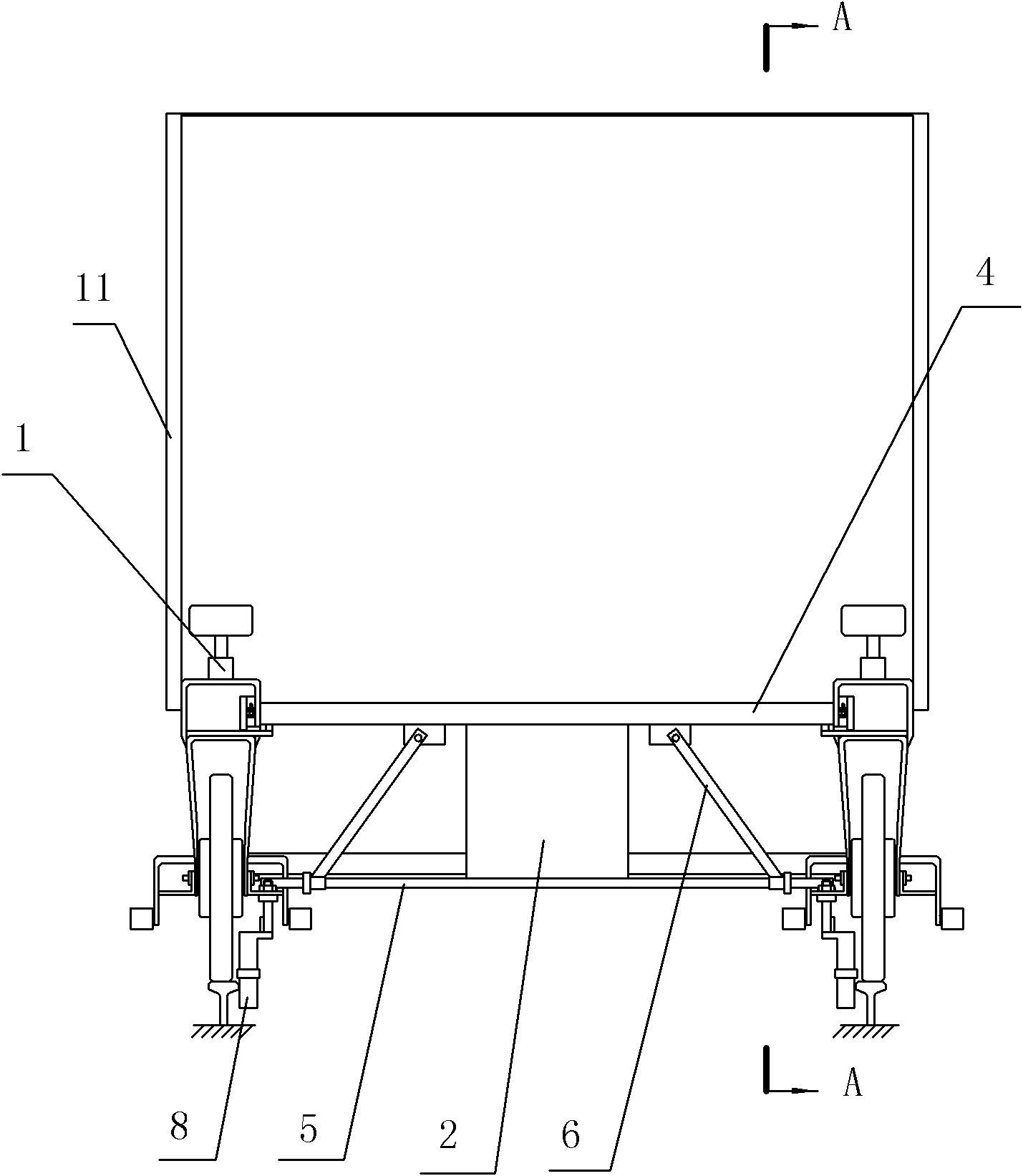

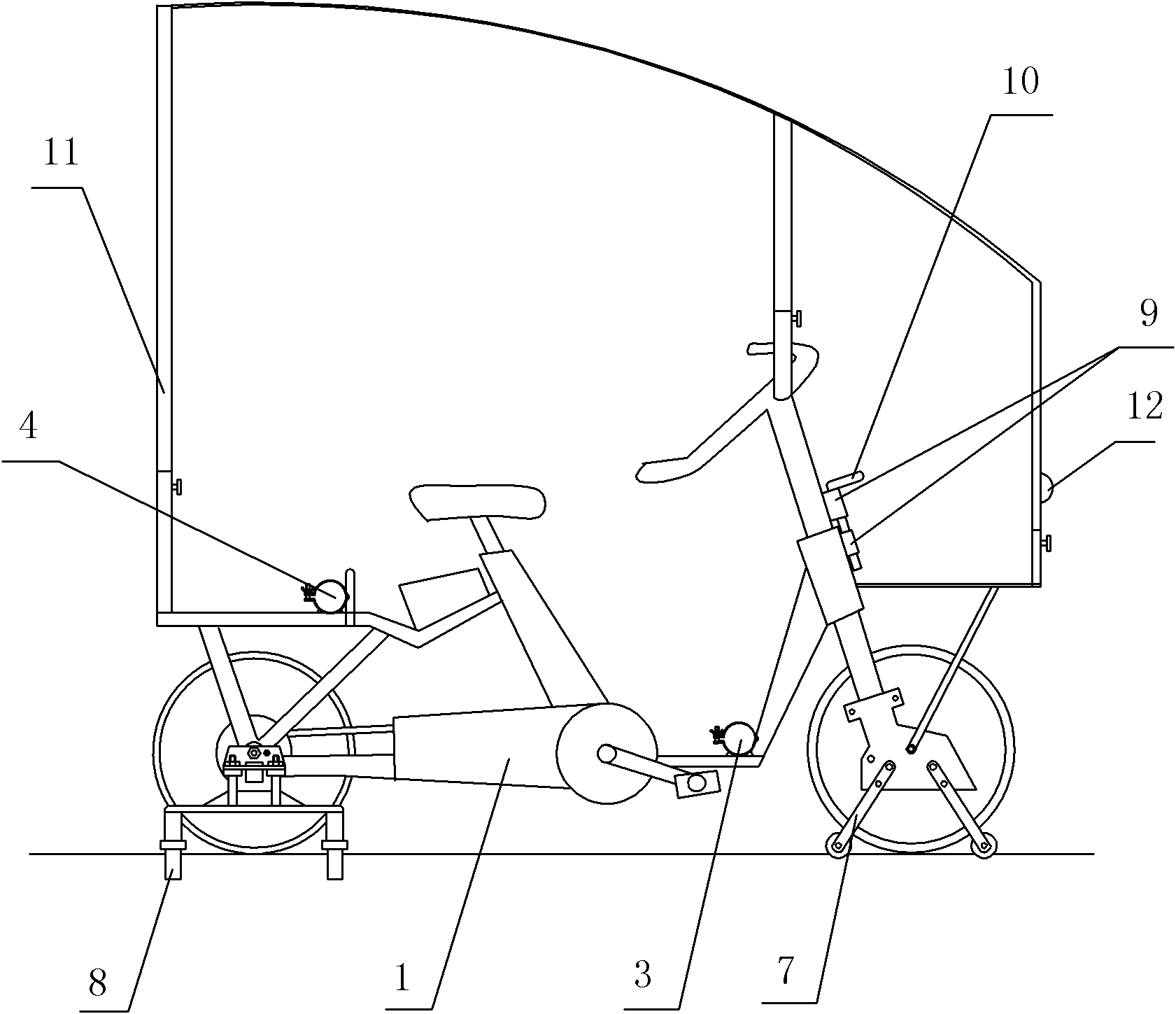

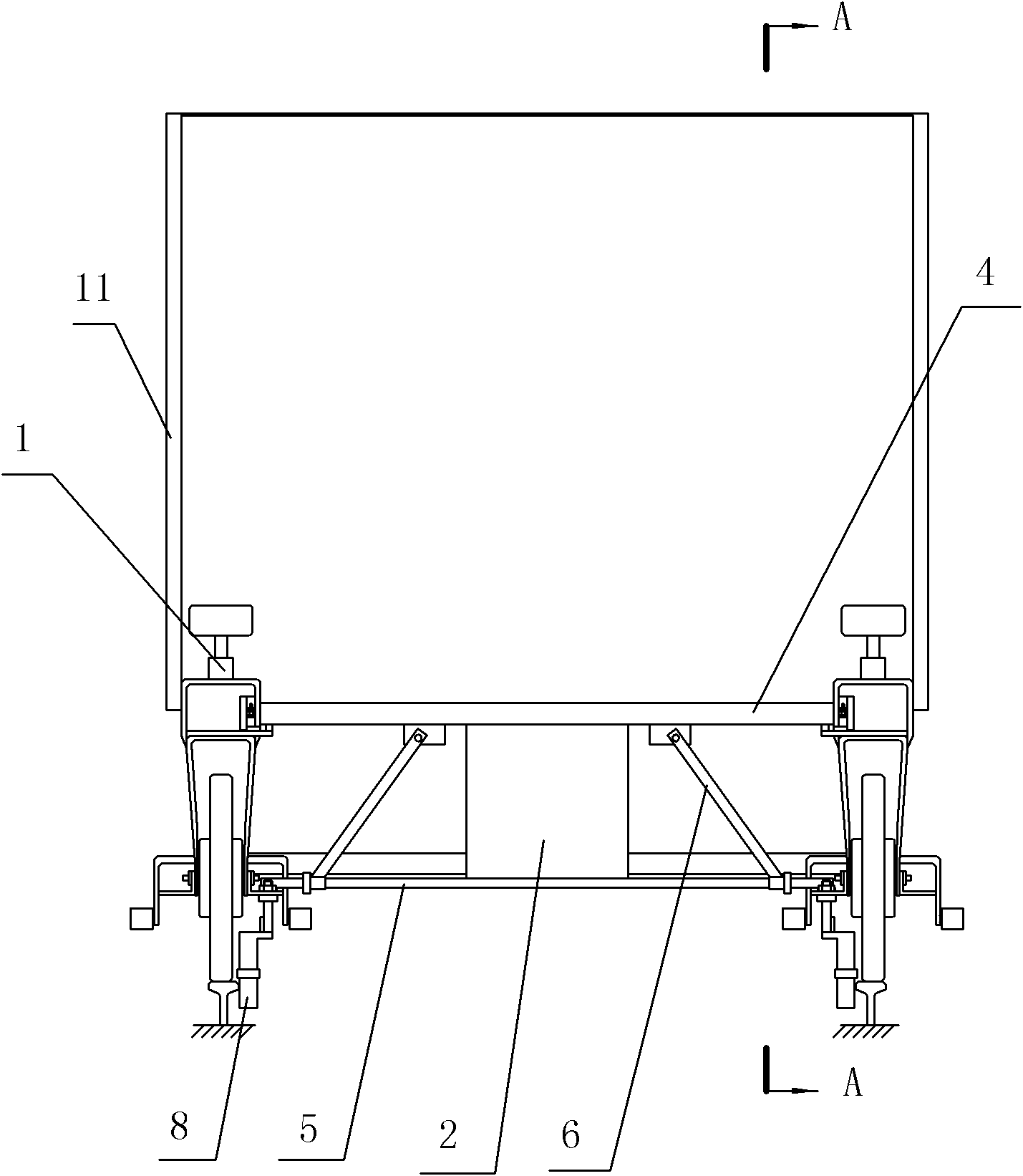

[0009] Such as figure 1 , figure 2 As shown, the high-speed railway light-duty inspection trolley includes two identical electric car bodies 1, and also includes a connecting device and a control device 2. The two electric car bodies 1 are connected through a connecting device, and the two ends of the connecting device Fast fixation is realized through the buckle fixing on the electric vehicle body 1, and the connecting device includes a front connecting rod 3 fixed on the front of the two electric vehicle bodies 1, a seat connecting rod 4 connected to the rear seat of the electric vehicle body 1 Connect the lower connecting rod 5 of the rear wheel of the electric vehicle body 1, and two reinforcing rods 6 are symmetrically arranged between the seat connecting rod 4 and the lower connecting rod 5; the control device 2 is fixed in the middle of the connecting device, And be electrically connected with electric vehicle body 1, be provided with lithium battery in the control de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com