Single-layer prestressing frame structure

A prestressed frame and prestressed technology, applied to structural elements, building components, building structures, etc., can solve problems such as uneven distribution of internal forces, achieve uniform distribution of internal forces, save structural materials, and achieve large economic spans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

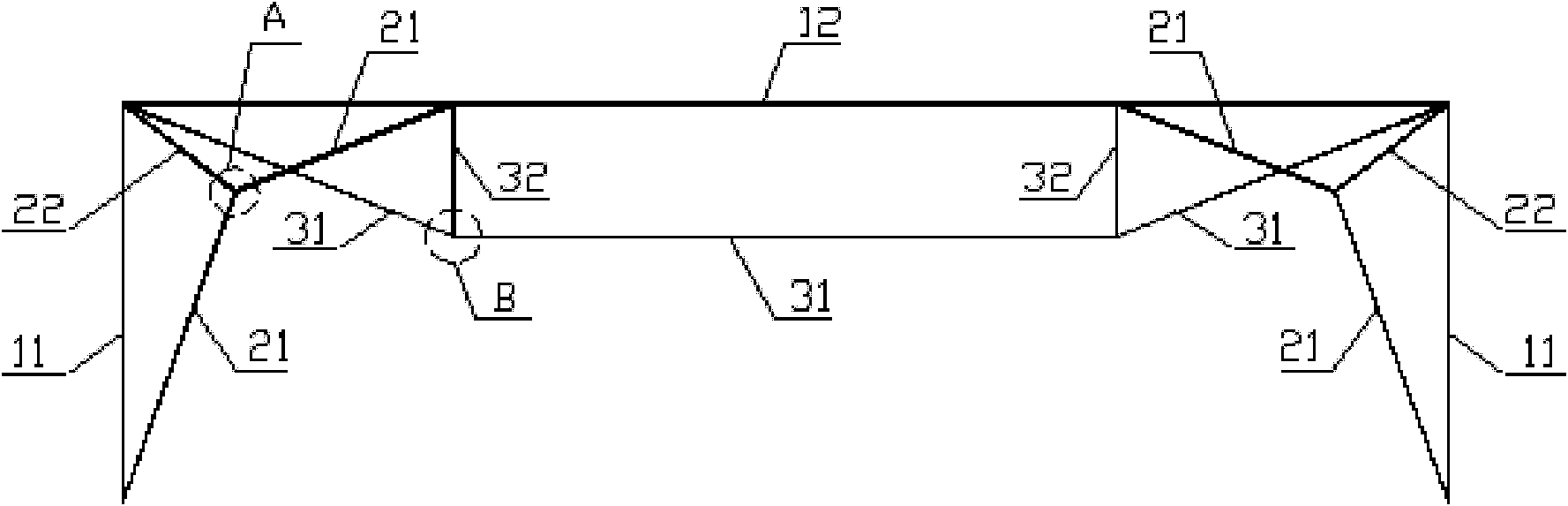

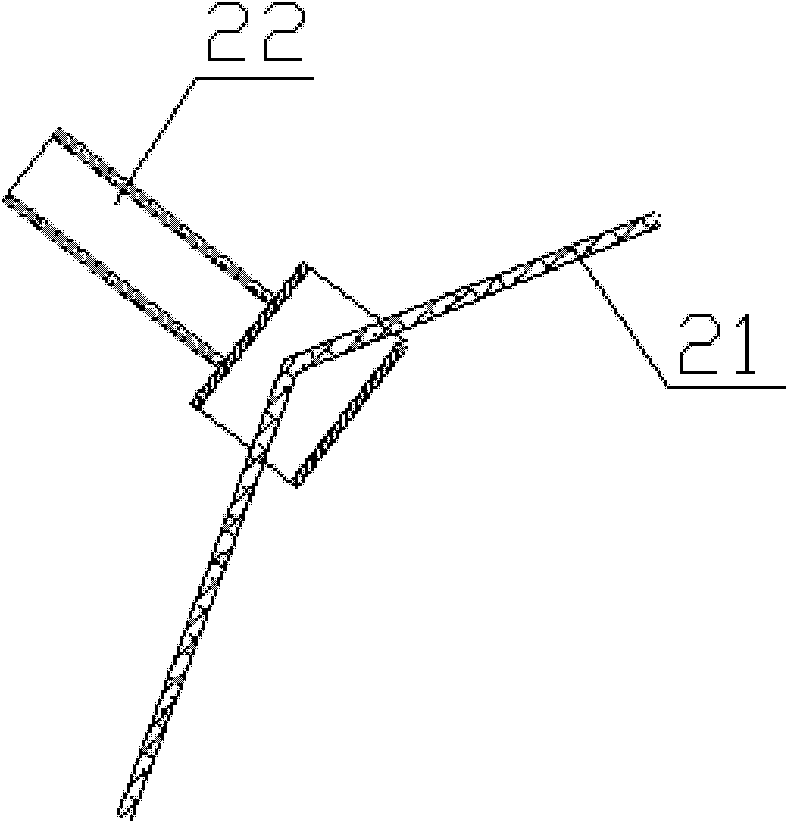

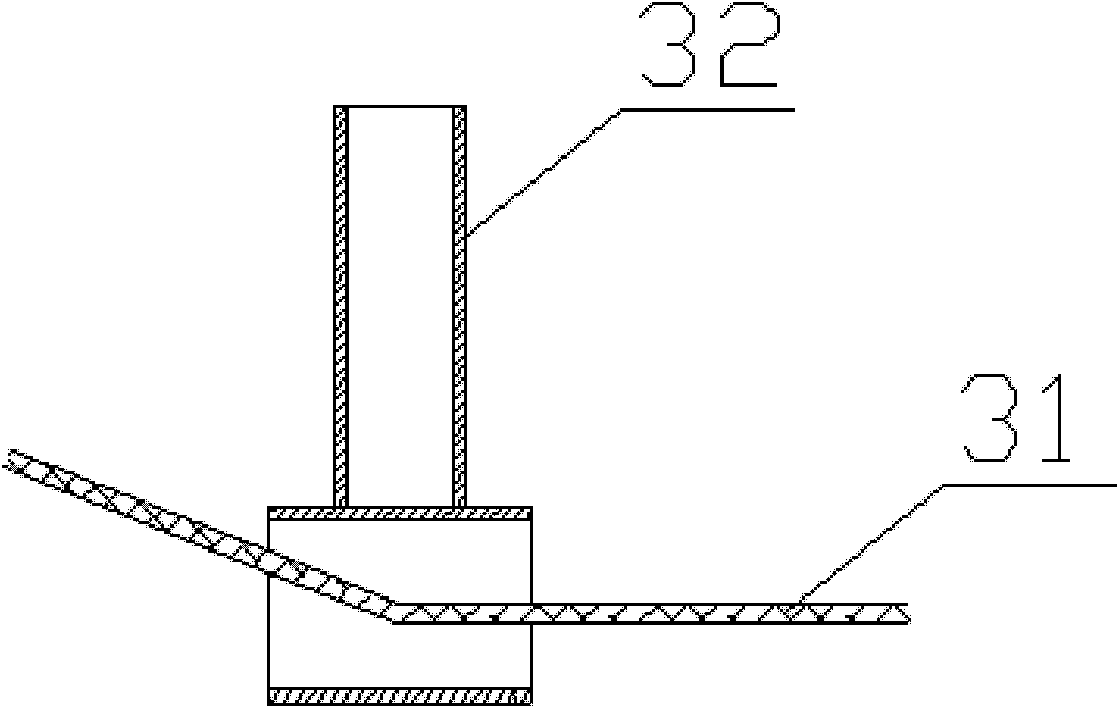

[0023] Such as figure 1 , figure 2 and image 3 As shown, a single-story prestressed frame structure with a structural span of more than 40m is composed of columns 11, beams 12, corner bracing systems and tensioning string systems. The columns 11 and beams 12 are welded and connected by H-shaped steel to form a frame. A corner bracing system is provided at the inner diagonal position of the connection point of the column 11 and the beam 12, and the corner bracing system is composed of a "T"-shaped brace 22 and a prestressed cable 21, and the "T"-shaped brace 22 is composed of Two round steel pipes are intersected and welded, and the prestressed stay cables 21 are steel wire ropes. The lower end of the "T"-shaped strut 22 is fixedly connected to the connection point between the beam 12 and the column 11, and the upper end of the "T"-shaped strut 22 is provided with a center line that is aligned with the axis of the beam 12 and the axis of the column 11. A plane through hol...

Embodiment 2

[0026] The structural span is between 15m and 40m, and the string tension system under the beam in Embodiment 1 can be omitted, which can be specifically implemented according to the following scheme:

[0027] Such as Figure 4 As shown, a single-layer prestressed frame structure is composed of columns 11, beams 12 and corner bracing systems. The columns 11 and beams 12 are welded and connected by H-shaped steel to form a frame. A corner bracing system is provided at the diagonal line inside the connection point of the beam 12 and the column 11, and the corner bracing system is composed of a "T" type brace 22 and a prestressed cable 21. The "T" type brace 22 is formed by intersecting welding of two circular steel pipes, and the prestressed stay cable 21 is a steel wire rope. The lower end of the "T"-shaped strut 22 is fixedly connected to the connection point between the beam 12 and the column 11, and the upper end of the "T"-shaped strut 22 is provided with a center line th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com