Group anchor structure for improving ductility of large foundation interface and concrete parameter correction method

A parameter correction, concrete technology, applied in basic structure engineering, construction, sheet pile wall and other directions, can solve the problem of not considering the influence of fiber-induced fatigue load and long-term effect, etc., to improve the cracking mode, improve the internal force distribution, improve the resistance The effect of crack strength and deformability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

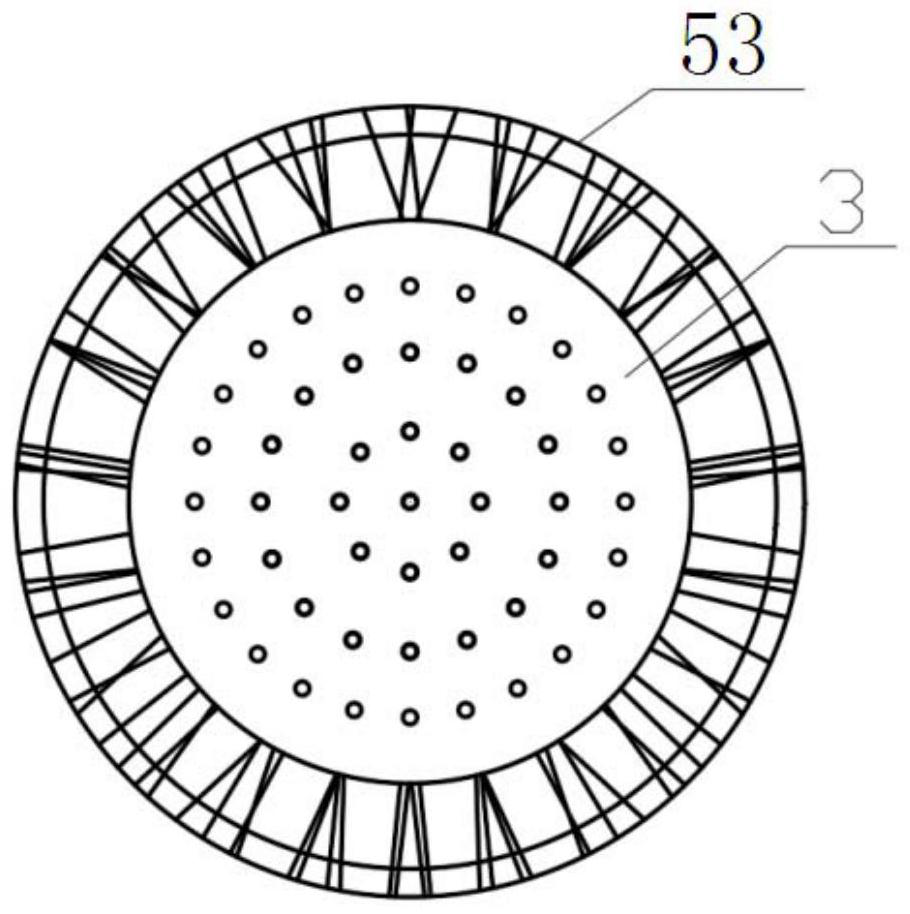

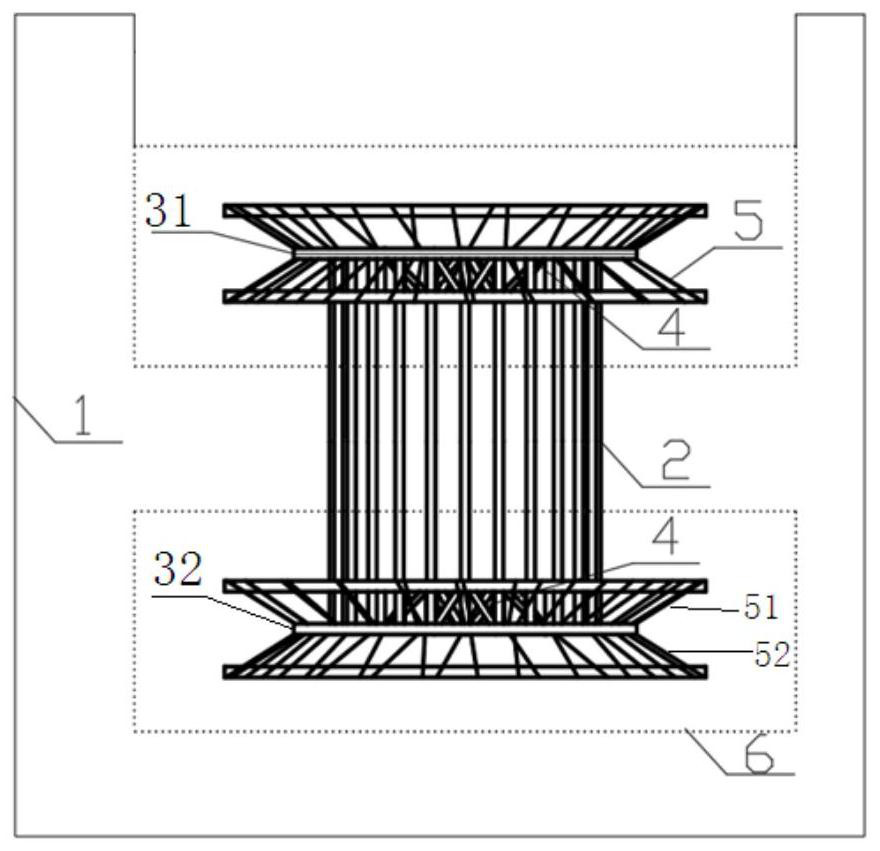

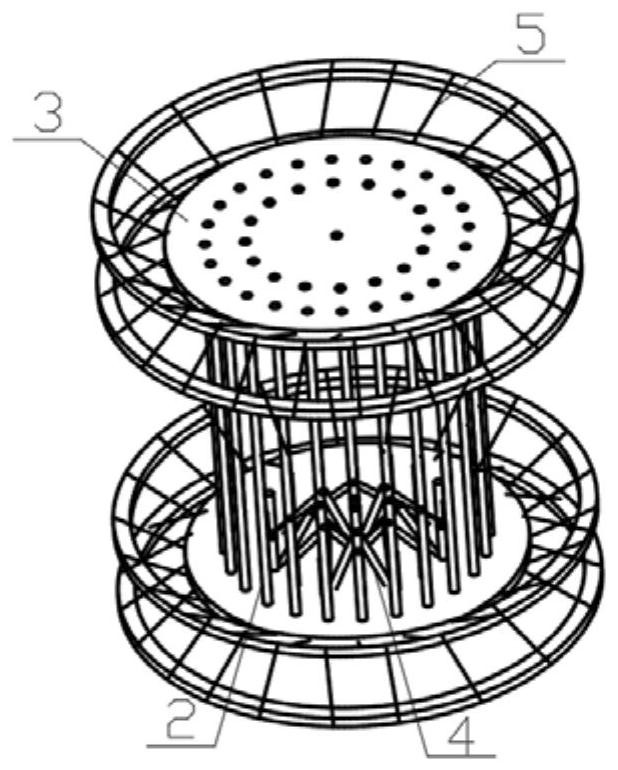

[0041] Example: as figure 1 As shown in the figure, a group anchor structure for improving the ductility of large-scale foundation interface, the group anchor structure is placed vertically inside the foundation, including: anchor bolt 2, anchor plate 3 (including upper anchor plate 31 and lower anchor plate 32), cage type Truss 4, X-shaped foundation shear arm 5 and fiber concrete 6.

[0042] The upper anchor plate 31 and the lower anchor plate 32 are located at the top and bottom of the foundation 1, and are connected by high-strength anchor bolts 2 through nuts. The cage truss 4 is connected with the anchor plate 3 by welding; the anchor plate 3 is located in the middle of the X-shaped foundation shear arm 5 . The anchor bolt 2 , the upper anchor plate 31 and the lower anchor plate 32 , the cage truss 4 and the X-shaped foundation shear arm 5 are integrated by pouring fiber concrete 6 .

[0043] In a specific embodiment, the design of the group anchor structure specifical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com