An installation structure and installation method of a wall casing

A technology of wall bushing and installation method, which is applied in the direction of lead-in/through-type insulator, spring/shock absorber, vibration suppression adjustment, etc., and can solve problems such as cracks, cracked flanges, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

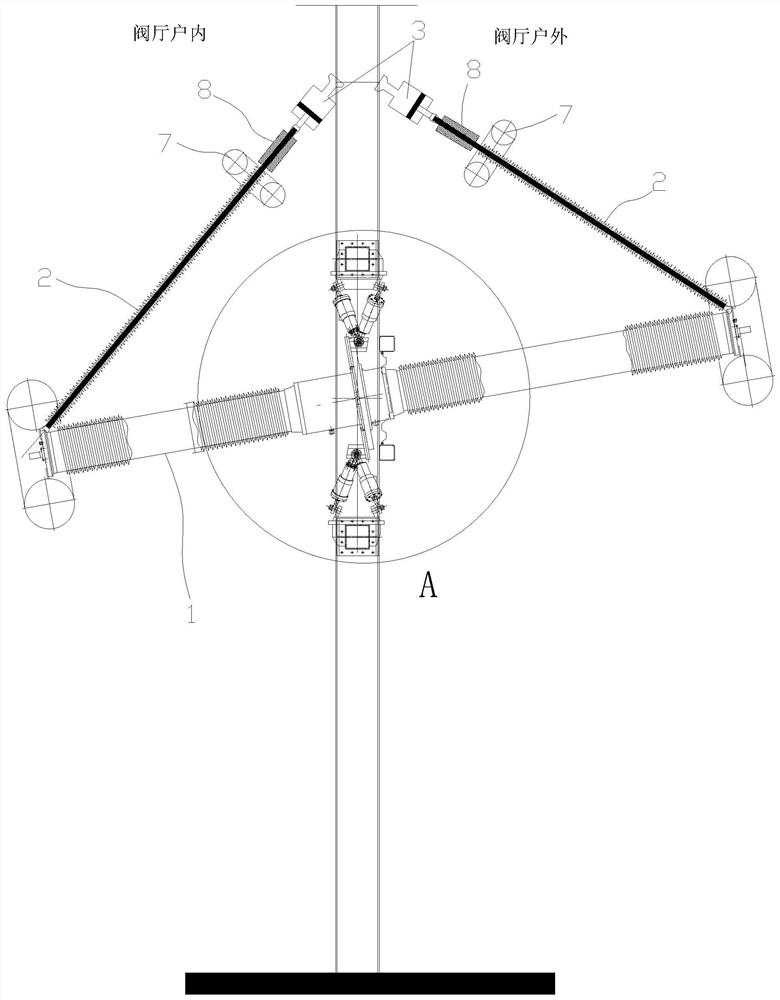

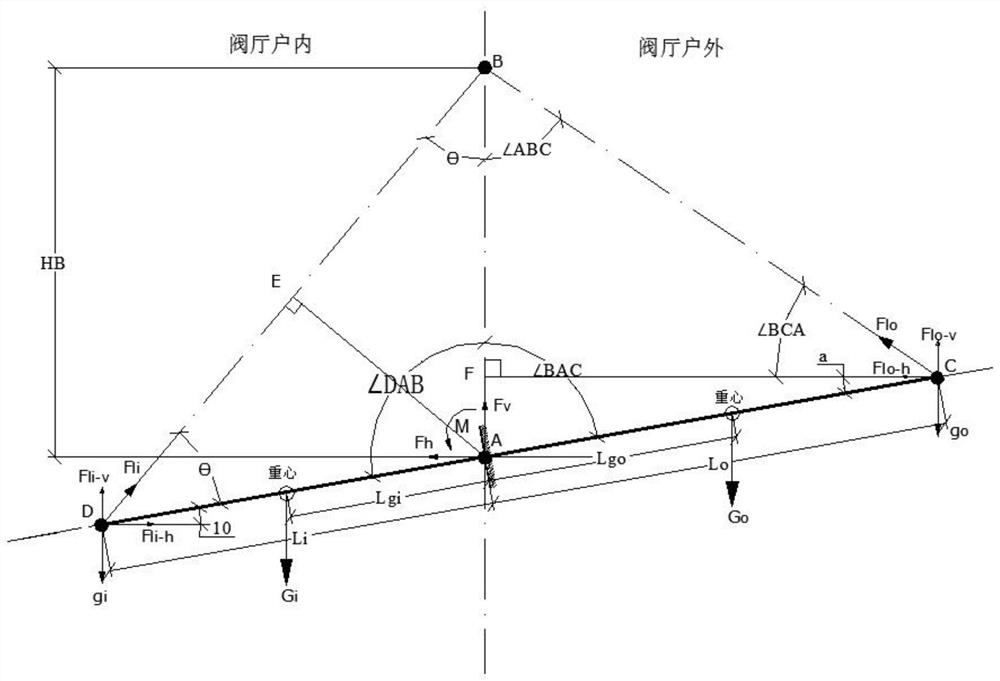

[0037] refer to figure 1 As shown, the wall bushing installation structure provided in this embodiment includes a wall bushing 1 and an insulating pull rod 2; wherein, the wall bushing 1 is installed behind the valve hall wall as a single fulcrum long cantilever structure. The two ends of the wall bushing 1 are respectively connected with insulating pull rods 2, and the other ends of the two insulating pull rods 2 are used to install in the wall of the valve hall, so that the wall bushing 1 and the two insulating pull rods 2 are three The whole forms a triangle shape. Wherein, the two insulating pull rods 2 are respectively an indoor insulating pull rod and an outdoor insulating pull rod.

[0038]In this way, the mechanical performance of the wall-piercing fulcrum of the wall-piercing bushing can be effectively improved by adding insulating rods. The pull rod can significantly reduce the gravity load and the bending moment under the action of vertical load on the cantilever ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com