Steel structure connecting device applying prestress

A connecting device and steel structure technology, which is applied in the direction of building structure, construction, etc., can solve the problems of complicated construction, single connection form, high cost of welding seams or bolts, etc., achieve clear force mechanism, simplify installation procedures, and save materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

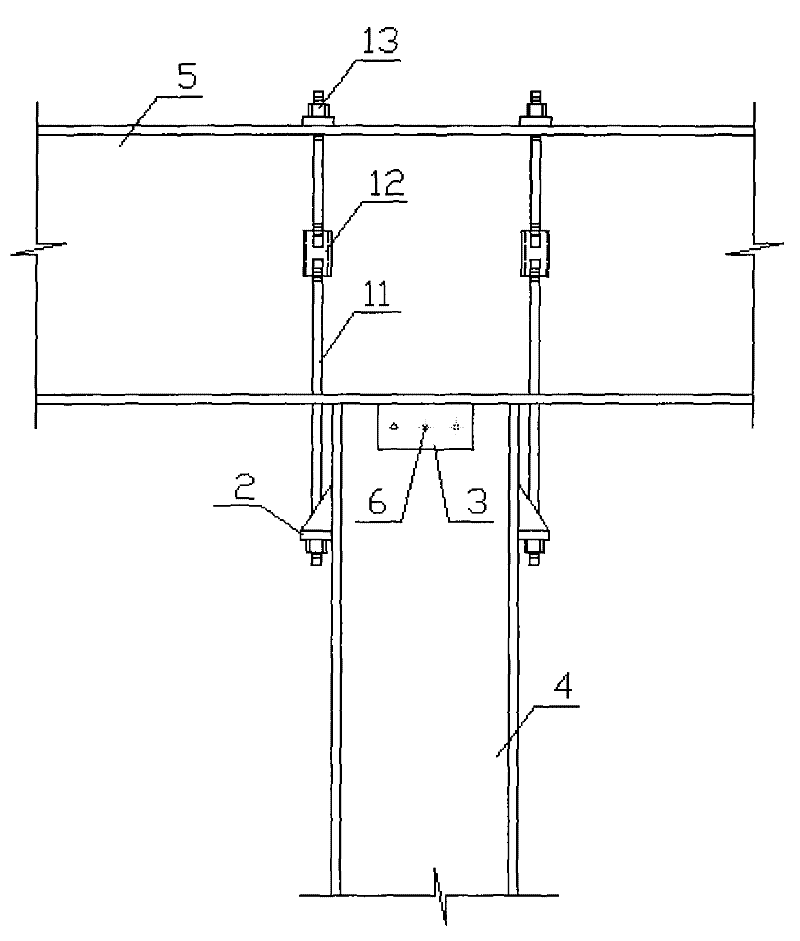

[0023] A prestressed steel structure connecting device of the present invention can be applied to such as Figure 6 The beam-to-column connection at node C is shown, where the beam at node C is a continuous member.

[0024] Figure 6 In the single-layer light steel portal frame shown, the beams and columns are welded H-shaped steel, the beam webs are placed vertically, and the column webs are placed along the beam length direction.

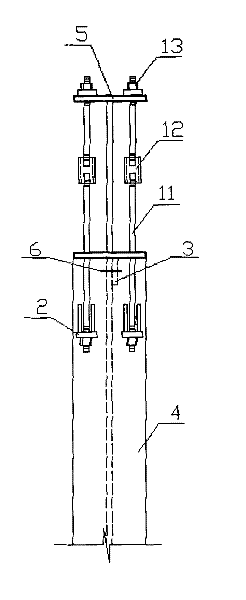

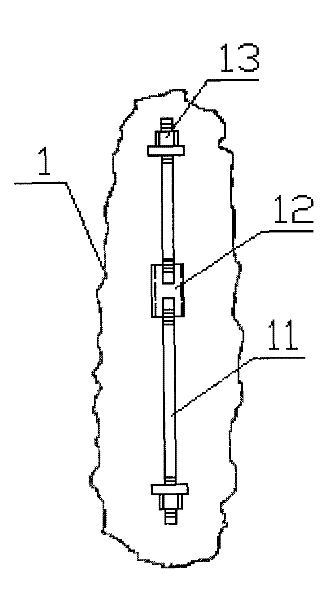

[0025] Such as figure 1 , figure 2 and image 3 As shown, the present invention is composed of a prestressed tie rod pair 1, a composite gusset plate 2, a shear key 3, a steel column 4 and a steel beam 5.

[0026] The prestressed tie rod pair 1 is formed by connecting two sections of steel tie rods 11 with threads at both ends through front and back buckle sleeves 12, and the steel tie rods 11 are high-strength round steel.

[0027] The combined gusset plate 2 is composed of three steel plates, one is a rectangular steel plate, and the other...

Embodiment 2

[0032] Figure 4 , Figure 5 The connection shown is suitable for use with Figure 6 The splicing node of components shown in node B is a special case of the present invention. Figure 6 In the single-layer light steel portal frame shown, the beam is welded H-shaped steel, and the beam web is placed vertically.

[0033] Such as image 3 , Figure 4 and Figure 5 As shown, the present invention is applied to a special case of component splicing, which is composed of a prestressed tie rod pair 1 , a combined gusset plate 2 , a shear key 3 and a steel beam 5 .

[0034] The prestressed tie rod pair 1 is formed by connecting two sections of steel tie rods 11 with threads at both ends through front and back buckle sleeves 12, and the steel tie rods 11 are high-strength round steel.

[0035] The combined gusset plate 2 is composed of three steel plates, one is a rectangular steel plate, and the other two are right-angled triangular steel plates. .

[0036] The prestressed tie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com