Scroll compressor

A technology of scroll compressors and compression chambers, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as refrigerant leakage, complicated manufacturing process of scroll compressors, performance degradation of scroll compressors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

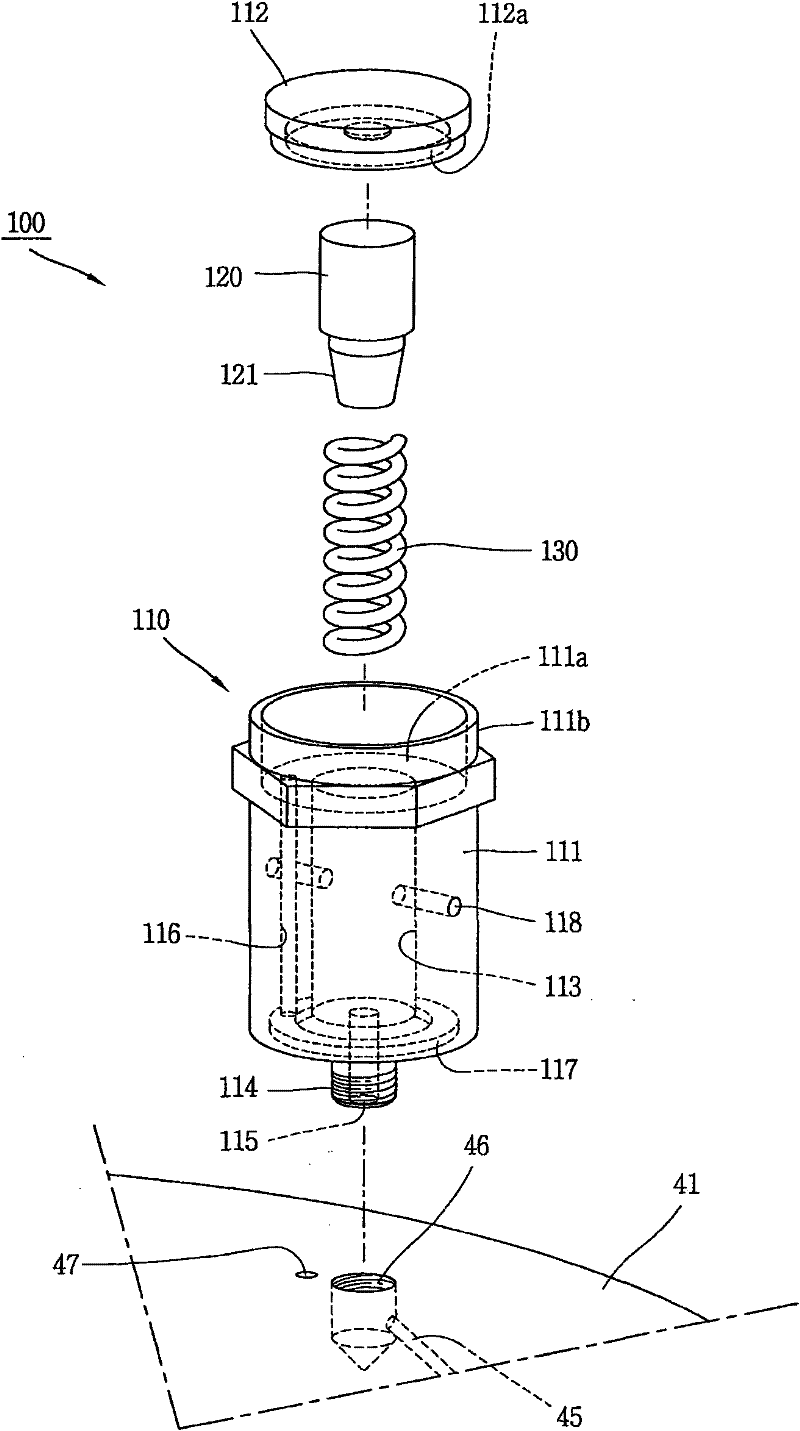

[0029] The present invention will now be described in detail with reference to the accompanying drawings.

[0030] For brief description with reference to the drawings, the same or corresponding components will be given the same reference numerals, and descriptions thereof will not be repeated.

[0031] Hereinafter, a scroll compressor according to the present invention will be explained in more detail with reference to the accompanying drawings.

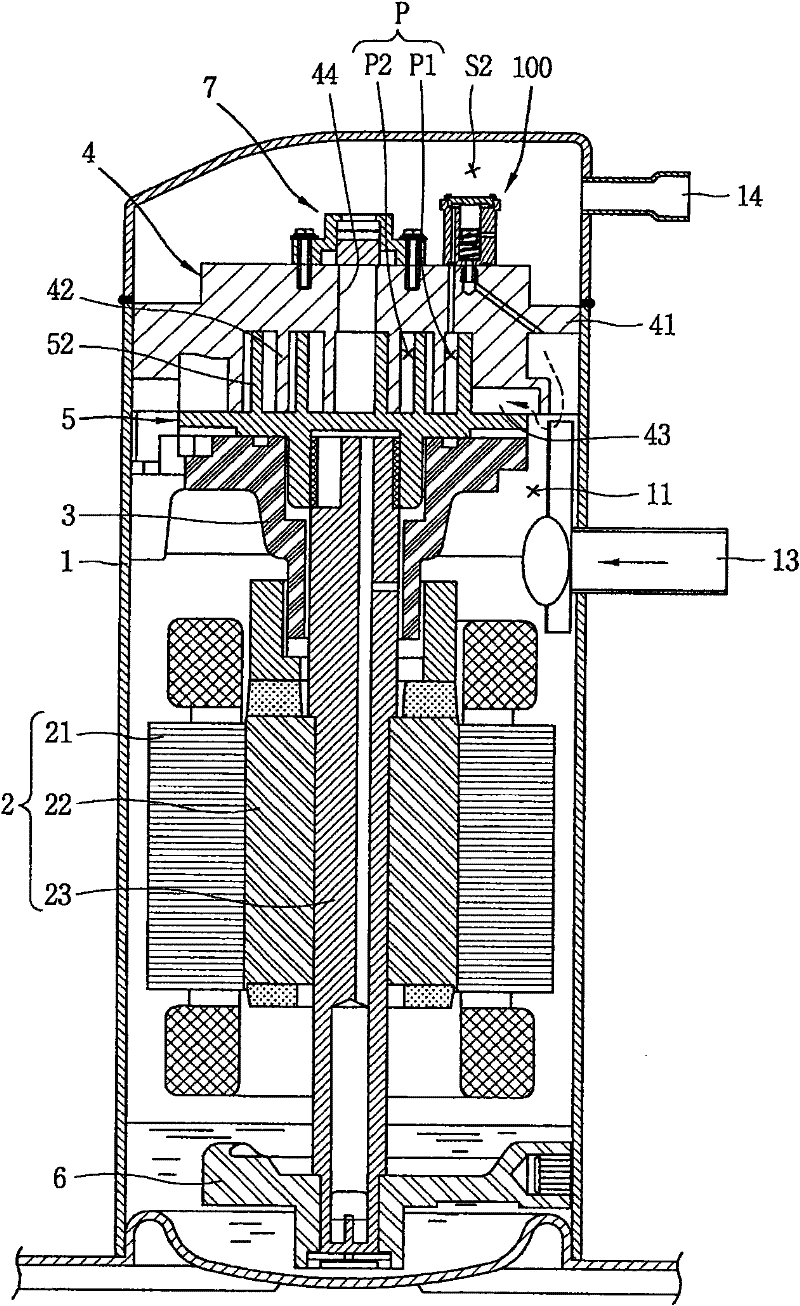

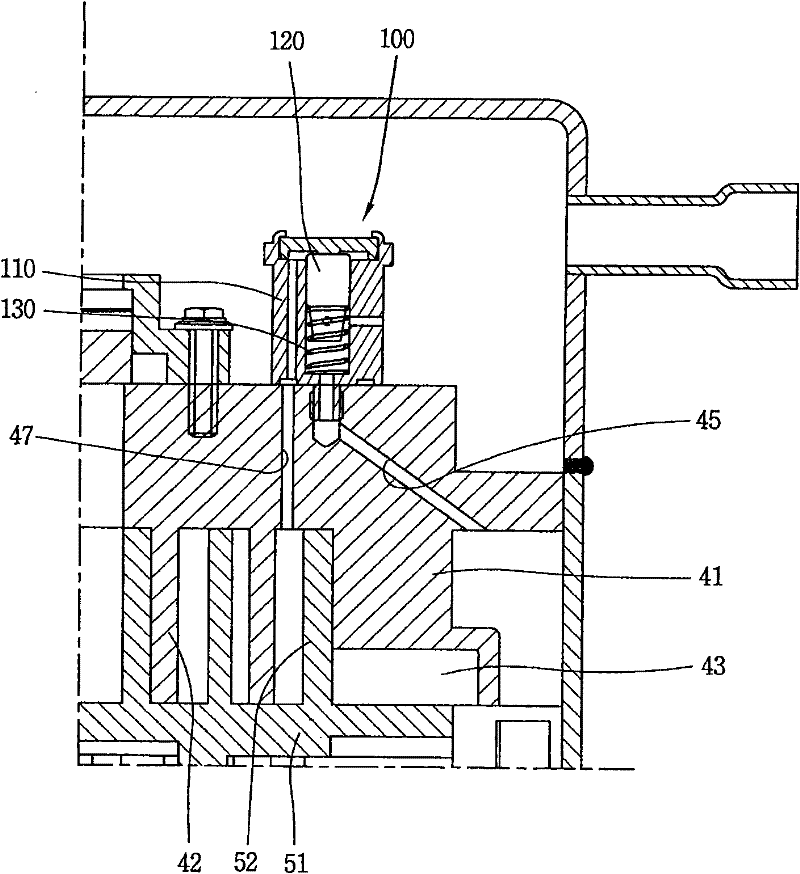

[0032] figure 1 is a longitudinal sectional view of a low-pressure scroll compressor according to the present invention.

[0033] As shown in the figure, a low-pressure type scroll compressor (hereinafter, referred to as a 'scroll compressor') according to the present invention includes: a hermetic container 1 having an inner space divided into suction as a low-pressure space; Space 11 and a discharge space 12 as a high-pressure space; a drive motor 2 installed in the suction space 11 of the airtight container 1 and generating a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com