Claw-type rotor profile

A claw-type and rotor technology, which is applied in the direction of rotary piston pumps, rotary piston machines, rotary piston/swing piston pump components, etc., can solve the problem of reducing the service life of claw rotors, poor sealing effect, and medium leakage Large and other problems, to achieve the effect of improving service life, improving volumetric efficiency, and enhancing sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

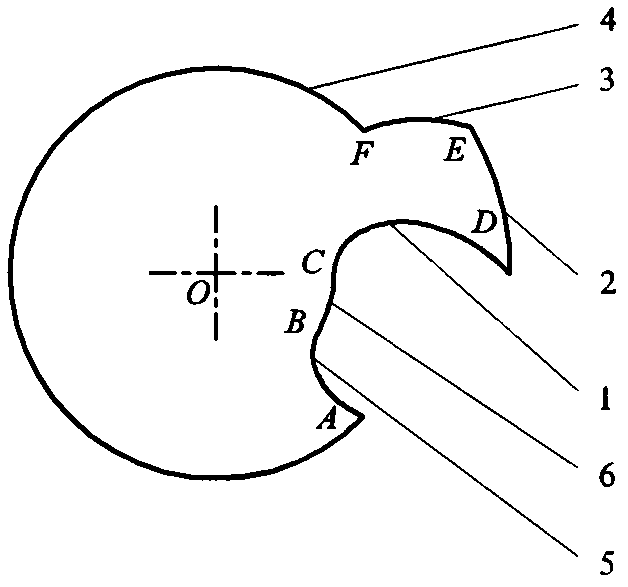

[0019] As shown in Figure 1, the original claw rotor profile is composed of three sections of arcs and three sections of cycloids, starting from the pitch circle in the counterclockwise direction: pitch circle arc FA, cycloid AB, claw bottom circle Arc BC, cycloid CD, claw top arc DE, and cycloid EF; the two connection points D and E of claw top arc DE are rough points, namely sharp points.

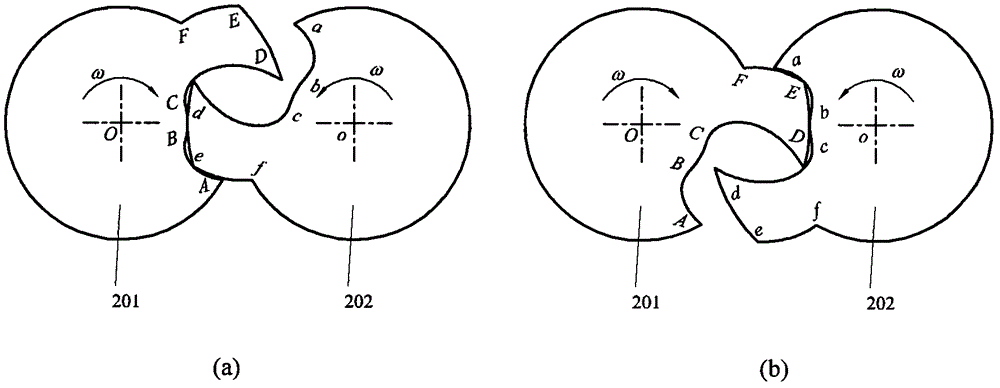

[0020] Such as figure 2 As shown, it is the working engagement diagram of the original two claw rotors; the two claw rotors have the same profile, and the relative rotation is staggered by a fixed angle. . (a) The cycloids AB and CD of the left rotor in the figure mesh with the points e and d of the right rotor respectively; (b) the points E and D of the left rotor in the figure respectively mesh with the points of the right rotor The cycloid ab and the cycloid cd mesh; it can be seen that the original claw rotor profile meshes with the curve during work.

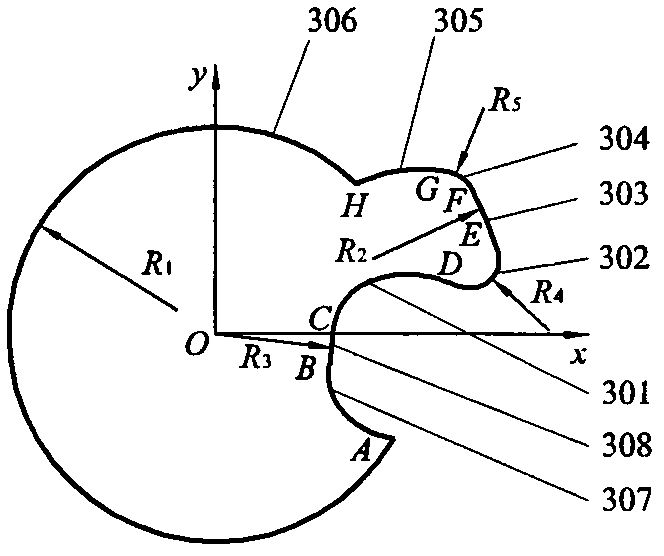

[0021] Such as image 3 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com