Laminated suction cup

A suction cup and lamination technology, applied in the direction of sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve the problems of increased production costs, and achieve weight reduction and good air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

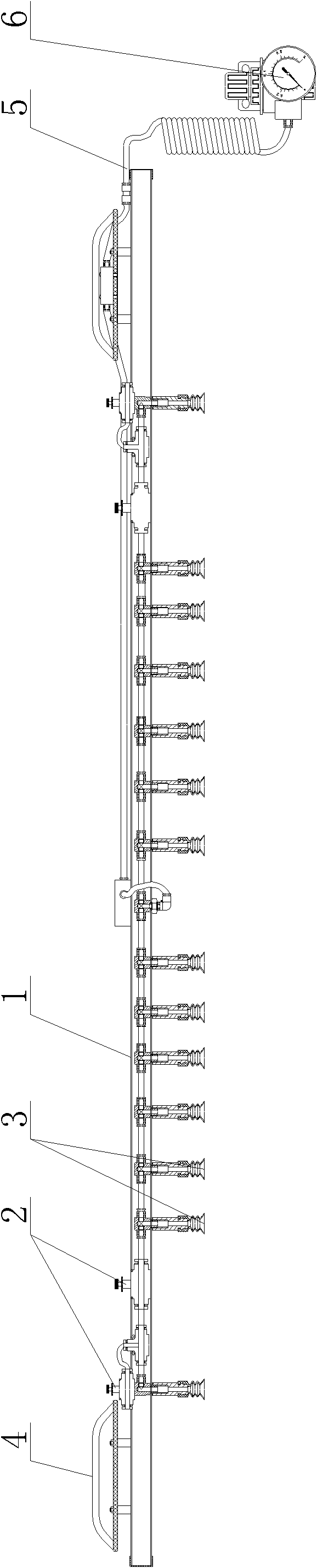

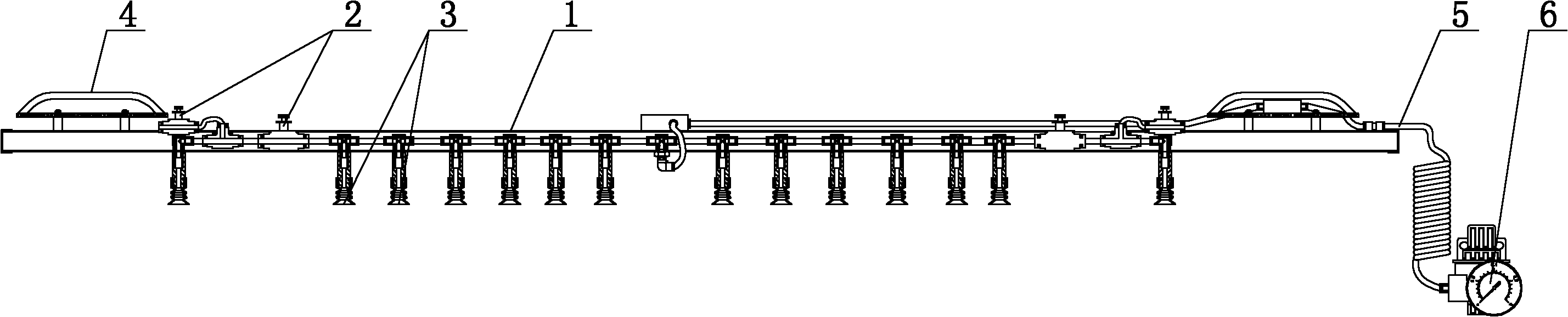

[0013] The present invention will now be described in further detail with reference to the accompanying drawings. These drawings are all simplified schematic diagrams, and only illustrate the basic structure of the present invention in a schematic manner, so they only show the structures related to the present invention.

[0014] like figure 1 The shown laminated suction cup is used for the layout of solar cell silicon wafers. The valve 2 is communicated with the air pressure valve 6 through the air pressure pipe 5. The air pressure of the air pressure valve 6 is 0.2-0.5MPa. The lower surface of the suction cup body 1 is installed with a number of suction heads 3 whose distances are adjusted according to the size of the solar cell silicon wafers. Adjust the opening or closing of the throttle valve 2 and adjust the spacing between the suction heads 3 to meet the layout of solar cell silicon wafers of different specifications. Two handles 4 are symmetrically arranged on the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com