Pipe network type dry powder fire extinguishing system and method

A dry powder fire extinguishing and pipe network technology, applied in fire rescue and other directions, can solve problems such as waste, inability to form a second or multiple fire extinguishing, and affecting the fire extinguishing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The system and method of the present invention are described in detail below in conjunction with the accompanying drawings and specific embodiments:

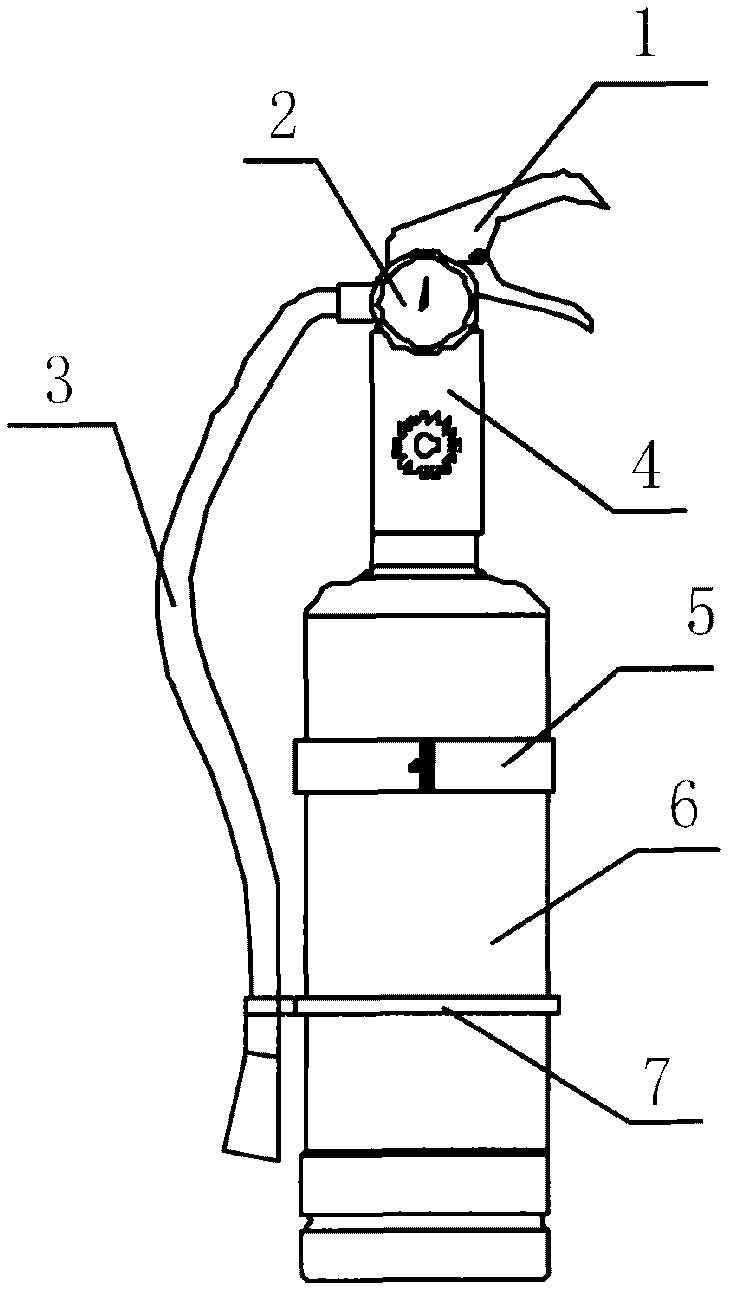

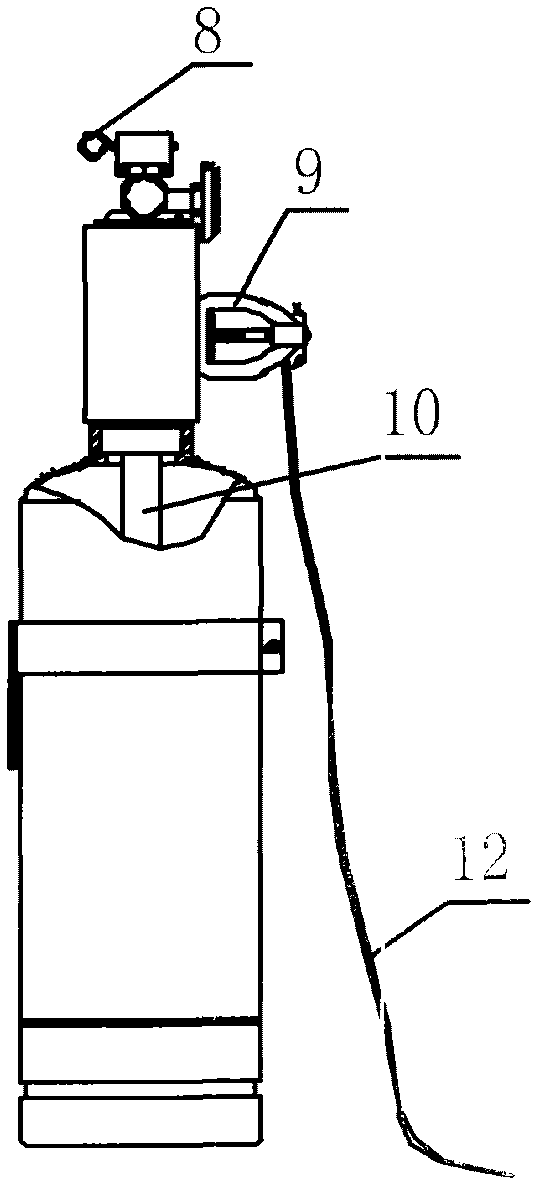

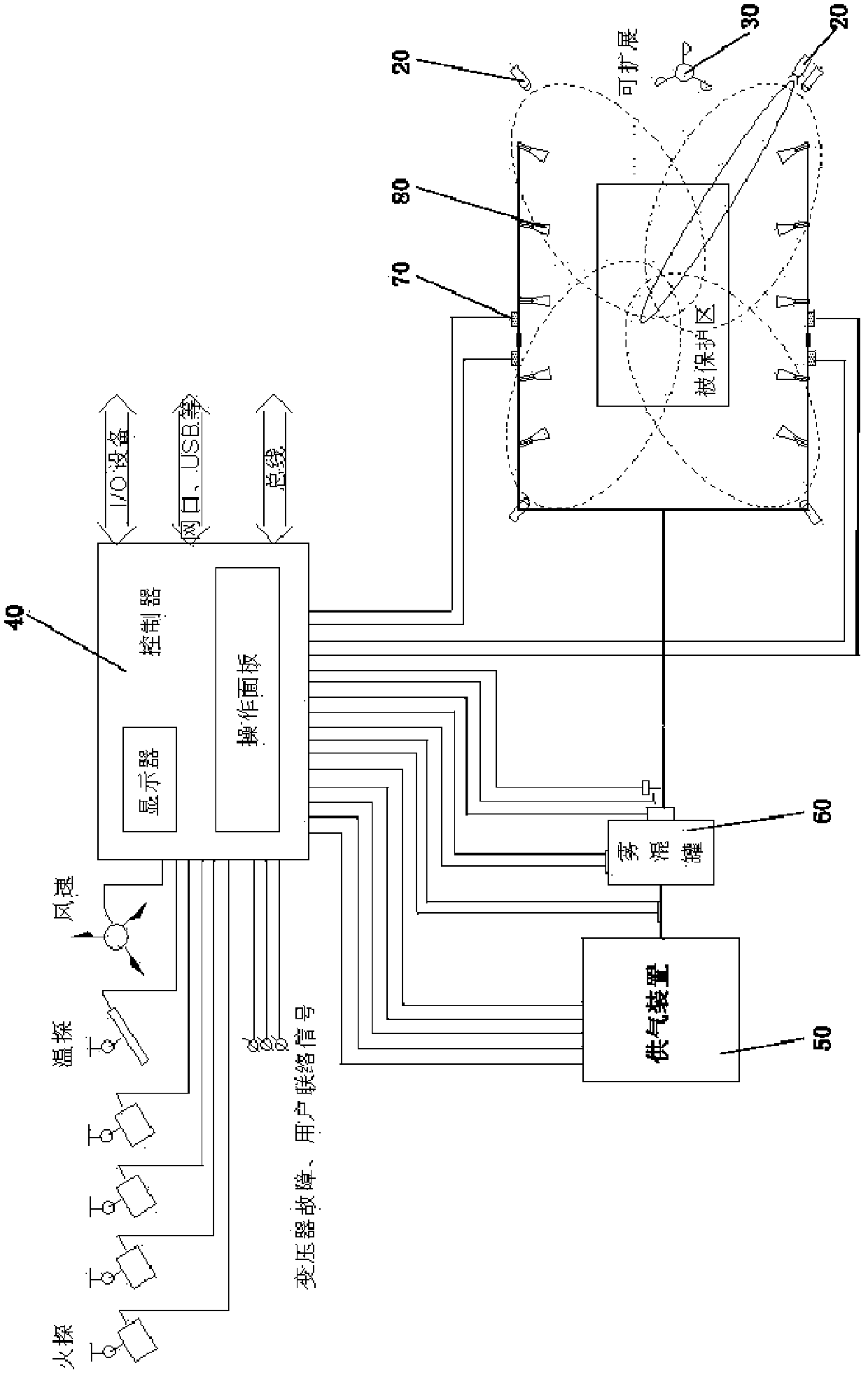

[0051] refer to image 3 , the pipe network type dry powder fire extinguishing system of the present invention mainly consists of fire source detector 10, temperature detector 20, wind speed detector 30, controller 40, air supply device 50, mist mixing tank 60, partition electric valve 70, nozzle 80 compositions. of the present invention figure 1 It only schematically draws a schematic diagram of a protected area. According to needs, the system can also be expanded, that is, according to the number of protected areas, fog mixing tanks and detectors are added to the corresponding protected areas. These increased Both the mixing tank and the detector are connected with the same controller 40, that is, a pipe network type dry powder fire extinguishing system is formed. Each part is described in detail below:

[0052] ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com