Work roll capable of improving edge drop control capability

A technology of control ability and work roll, applied in the direction of manufacturing tools, rolls, metal rolling, etc., can solve the problem that the qualification rate is difficult to meet the needs of users, reduce the competitiveness of cold-rolled products, etc., to improve the edge drop control ability, improve metal Flow volume and flow uniformity, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

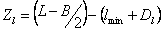

[0029] A work roll with improved edge drop control capability, the end roll shape of the work roll is a function curve, and the function is a polynomial power function, and the feature is that the intersection point of the extension line of the work roll body and the end line extension line is taken as the origin , the axial direction of the work roll is the abscissa, and the radial direction of the work roll is the ordinate; that is, the relative length of the roll-shaped end curve area is the abscissa value, and the relative height of the roll-shaped end curve area is the ordinate value. The function equation of the end curve of shape for

[0030] (1)

[0031] (2)

[0032] In the formula: - The length of the curved roll shape that needs to be processed at the end of the work roll, in mm;

[0033] - the total length of the straight line of the work roll surface, in mm;

[0034] — is the average width of the rolled piece, in mm;

[0035] —The length of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com