Silicon carbide rubber sanding block for polishing and grinding glazed tile

A technology of silicon carbide and glazed tiles, applied in abrasives, metal processing equipment, manufacturing tools, etc., can solve the problems of increasing product cost expenditure, reducing enterprise economic benefits, grinding block loss, etc., to avoid scratching products, and the structure is simple and reasonable , Reasonable effect of grinding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

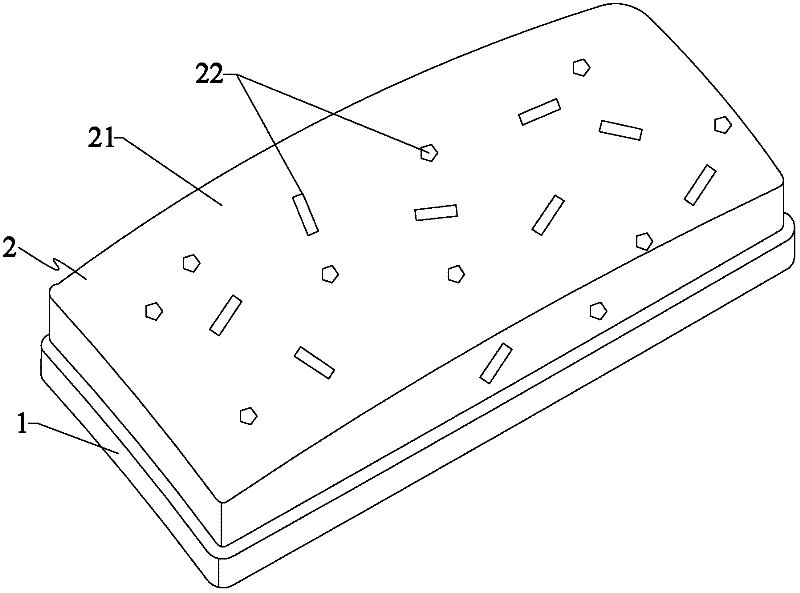

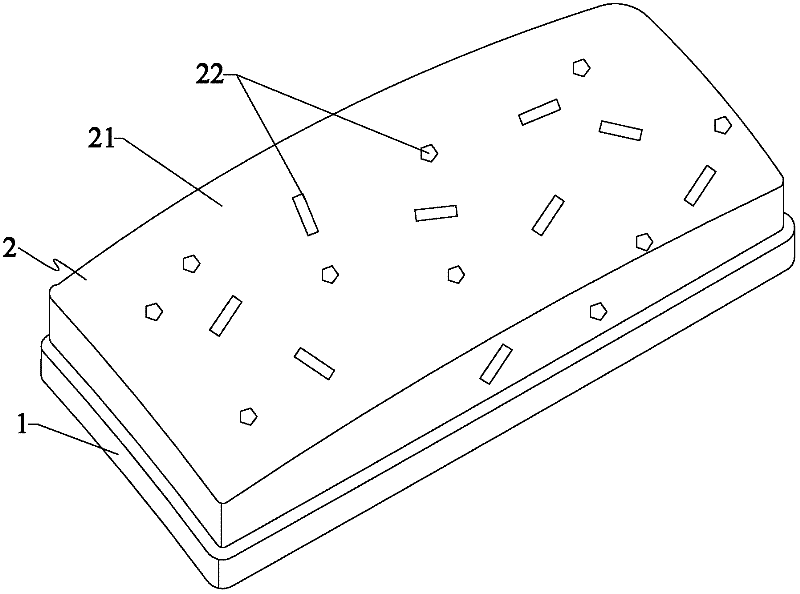

[0018] Such as figure 1 As shown, the silicon carbide rubber grinding block used for polishing glazed tiles according to the present invention includes a rubber-plastic clamping plate 1 and a silicon carbide rubber grinding block 2, and the silicon carbide rubber grinding block 2 passes through an adhesive and a rubber-plastic grinding block. The card board 1 is bonded and fixed.

[0019] The above-mentioned silicon carbide rubber grinding block 2 adopts rubber powder 21 as the basic body, and then mixes silicon carbide 22 in the rubber powder to form an integral molding by sintering and die-casting. is 15mm.

[0020] The present invention can be rotated during the grinding work, and when the workpiece to be ground enters the range of the silicon carbide rubber grinding block, the silicon carbide rubber grinding block will perform powerful grinding on the workpiece, thereby grinding out a clear, transparent and beautiful ideal artifact.

[0021] The present invention is not...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com