SAPO-34 molecular sieve preparation method

A technology of SAPO-34 and molecular sieve, which is applied in the field of preparation of SAPO-34 molecular sieve, can solve the problems of multiple energy sources, multiple processes, and difficulty in increasing environmental protection, and achieves the effect of high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a preparation method of SAPO-34 molecular sieve, especially the preparation method of SAPO-34 in the case of leakage from a crystallization reactor.

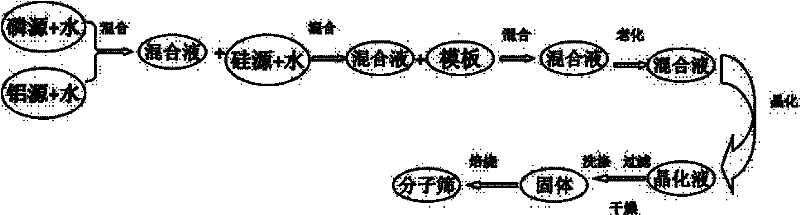

[0035] The present invention relates to the preparation method of SAPO-34 molecular sieve on the one hand, comprises the following steps:

[0036] (a) provide template agent, aluminum source, phosphorus source, silicon source water mixture;

[0037] (b) mixing each water mixture of step (a) in a mixing tank to form a slurry;

[0038] (c) transporting the slurry mixed into the glue tank to the crystallization reactor;

[0039] (d) The slurry is subjected to a crystallization reaction in a crystallization reactor;

[0040] (e) solid-liquid separation is carried out to the crystallized slurry, and the solid product is recovered;

[0041] (f) the solid product obtains molecular sieves through drying and roasting procedures;

[0042] Wherein, before the crystallization reaction, the templating agent is...

Embodiment 1

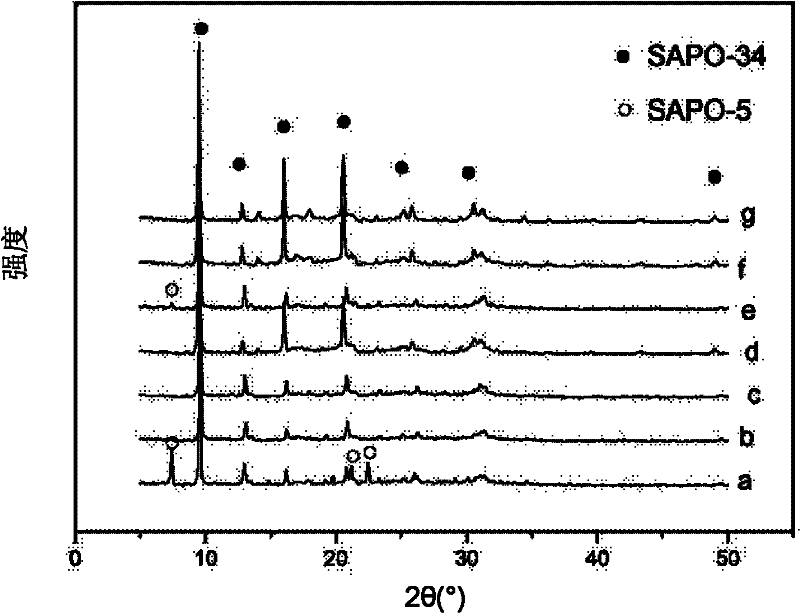

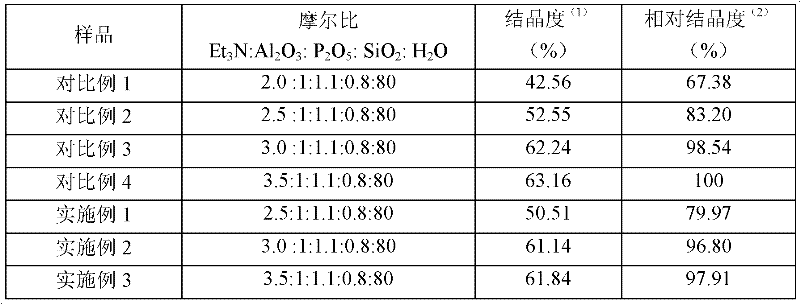

[0079] Phosphoric acid, pseudo-boehmite, 40% silica sol, triethylamine, and deionized water are mixed according to the molar ratio of 2.5Et 3 N:Al 2 o 3 : 1.1P 2 o 5 : 0.8SiO2 2 :80H 2 O and figure 1 The process shown is for preparation, wherein the aging conditions are: temperature: 25°C, time: 2 hours; the crystallization conditions are set as: temperature: 200°C, time: 48 hours, and the setting value of the safety valve of the high-pressure crystallization tank is set to When the crystallization time is 5h, the system pressure reaches 2.78MPa, the safety valve takes off, and after the pressure is relieved instantly, the safety kettle automatically resets, but the reset seal is not tight, and triethylamine still leaks during the entire crystallization process. Roasting conditions: temperature: 550°C, time: 6 hours; finally product e was obtained.

Embodiment 2

[0081] Phosphoric acid, pseudo-boehmite, 40% silica sol, triethylamine, and deionized water are mixed according to the molar ratio of 3.0Et 3 N:Al 2 o 3 : 1.1P 2 o 5 : 0.8SiO2 2 :80H 2 O and figure 1 The process shown is for preparation, wherein the aging conditions are: temperature: 25°C, time: 2 hours; the crystallization conditions are set as: temperature: 200°C, time: 48 hours, and the setting value of the safety valve of the high-pressure crystallization tank is set to When the crystallization time is 5h, the system pressure reaches 2.78MPa, the safety valve takes off, and after the pressure is relieved instantly, the safety kettle automatically resets, but the reset seal is not tight, and triethylamine still leaks during the entire crystallization process. Roasting conditions: temperature: 550°C, time: 6 hours; finally product f was obtained.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap