High-definition back projection film and preparation method thereof

A projection film, high-definition technology, applied in projection devices, instruments, optics, etc., can solve the problems of small gain viewing angle, affecting light transmission and projection effect, and high gain, achieving large gain viewing angle, good clarity and color reproduction, Great diffusive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

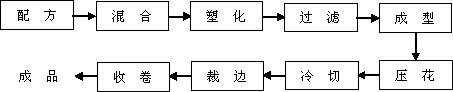

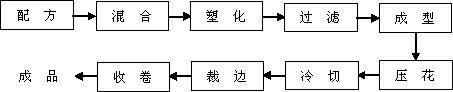

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: a kind of formula of high-definition rear projection film, by weight:

[0032] 100 parts of PVC with a degree of polymerization of 1800,

[0033] Dioctyl phthalate (DOP) 60 parts,

[0034] 6 parts of barium zinc stabilizer,

[0035] 8 parts of powdered nitrile rubber,

[0036] Ultramarine 3 parts,

[0037] Silicone light diffusing agent 10 parts.

Embodiment 2

[0038] Embodiment 2: the prescription of another kind of high-definition rear projection film, by weight:

[0039] 100 parts of PVC with a degree of polymerization of 1800,

[0040] Dioctyl phthalate (DOP) 55 parts,

[0041] 5 parts of barium cadmium zinc stabilizer,

[0042] 8 parts liquid nitrile rubber,

[0043] 2 parts carbon black,

[0044] Silicone light diffusing agent 8 parts.

Embodiment 3

[0045] Embodiment 3: Another kind of formula of high-definition rear projection film, by weight:

[0046] 100 parts of PVC with a degree of polymerization of 1800,

[0047] Diisononyl phthalate (DINP) 65 parts,

[0048] 5 parts of barium cadmium zinc stabilizer,

[0049] Liquid nitrile rubber 15 parts,

[0050] 4 parts phthalocyanine,

[0051] Silicone light diffusing agent 12 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com