Mining system for marginal oil field with marine heavy oil and method

A marginal oil field and development system technology, applied in the field of steam preparation technology and injection technology, can solve problems such as uneconomical, heat loss, high cost, etc., and achieve the effect of saving development costs and flexible layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

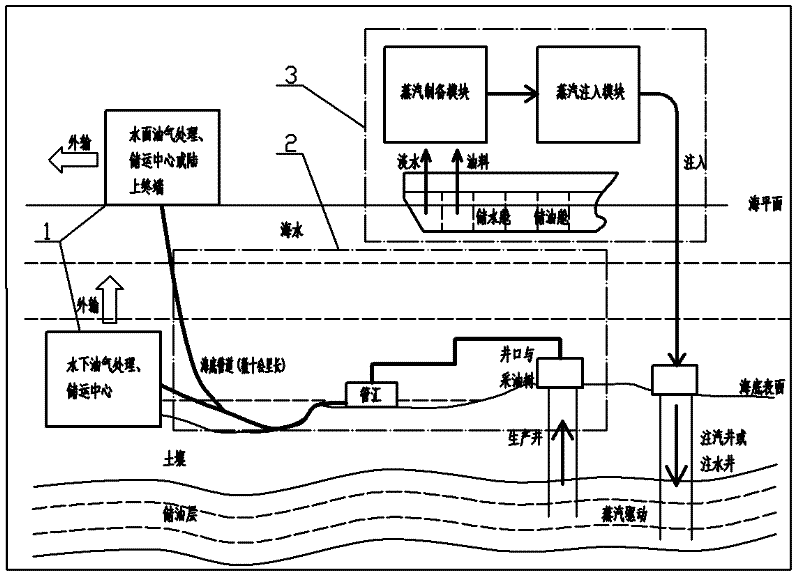

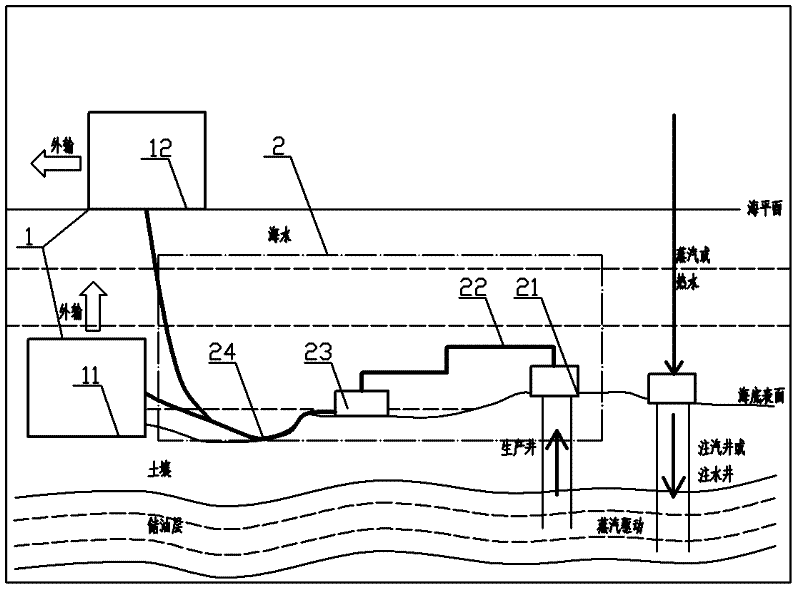

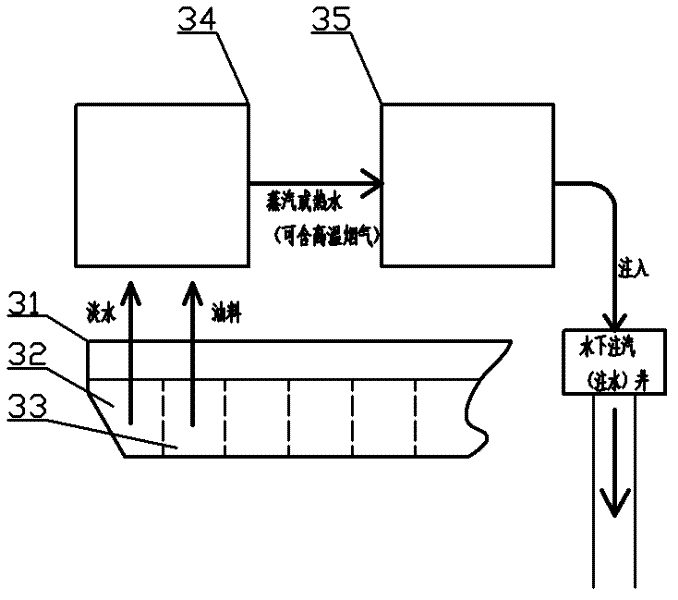

[0035] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1-3 As shown, a development system for offshore heavy oil marginal oil fields includes an oil and gas processing and storage subsystem 1 and an underwater production subsystem 2, and also includes a mobile steam preparation and injection subsystem 3, and the mobile steam preparation and injection subsystem 3 Including a carrying module 31, an oil storage tank 32, a water storage tank 33, a steam preparation module 34 and a steam injection module 35, the carrying module 31 is a self-propelled ship with a main engine or a floating structure without a main engine towing; The oil and gas processing, storage and transportation subsystem 1 is a surface oil and gas processing, storage and transportation center 12 or an underwater oil and gas processing, storage and transportation center 11 .

[0036] The steam injection module 35 of the present invention includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com