Current measuring device and current measuring method thereof

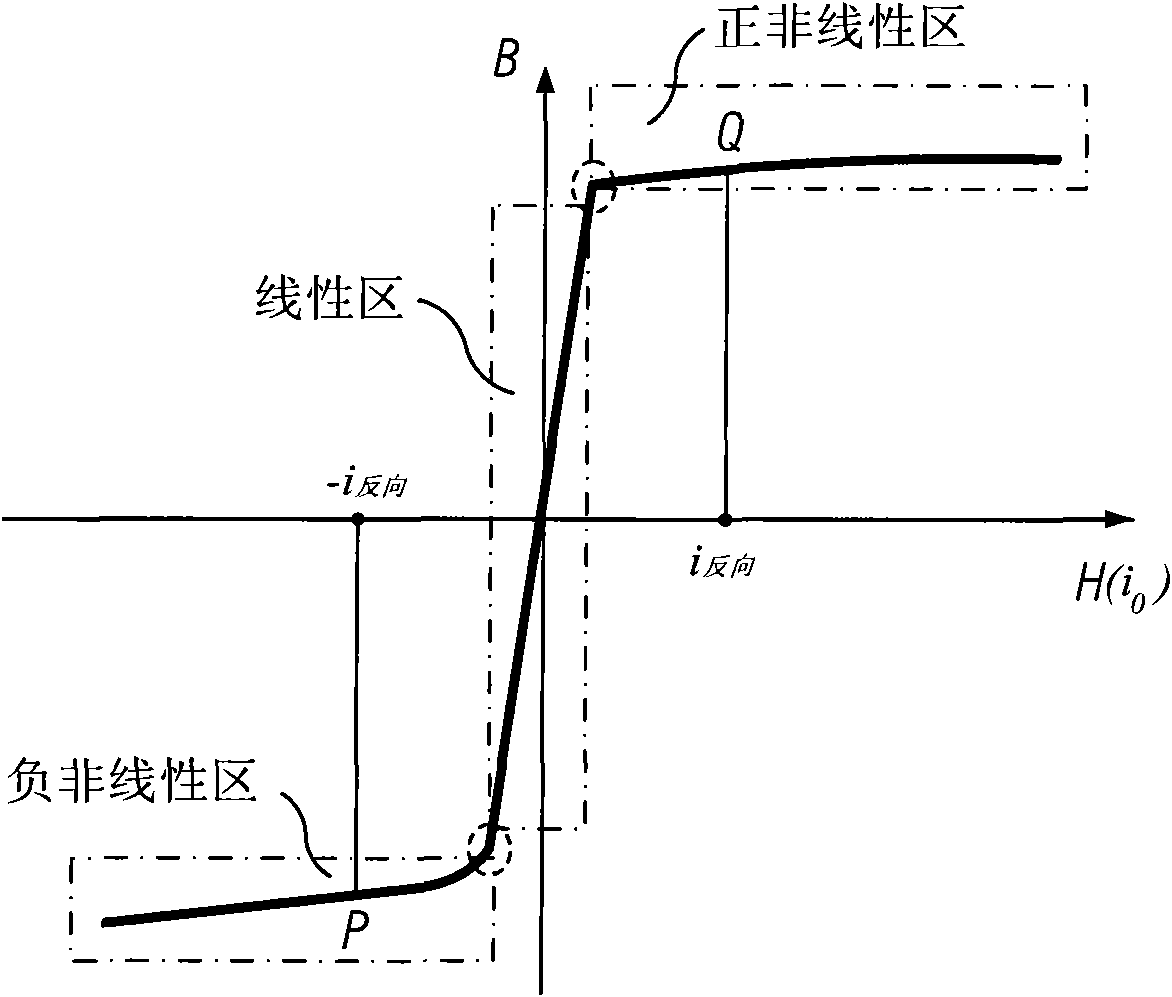

A current measurement device and electrical connection technology, applied in the direction of measurement device, measurement of electrical variables, measurement of magnetic variables, etc., can solve problems such as affecting the accuracy of current measurement, high power loss, increasing circuit complexity, etc., to achieve automatic magnetic reset, The effect of reducing working time and measuring power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to have a clearer understanding of the technical features, purposes and effects of the invention, the specific embodiments of the present invention are now described with reference to the accompanying drawings, in which the same reference numerals represent components with the same or similar structures but the same functions.

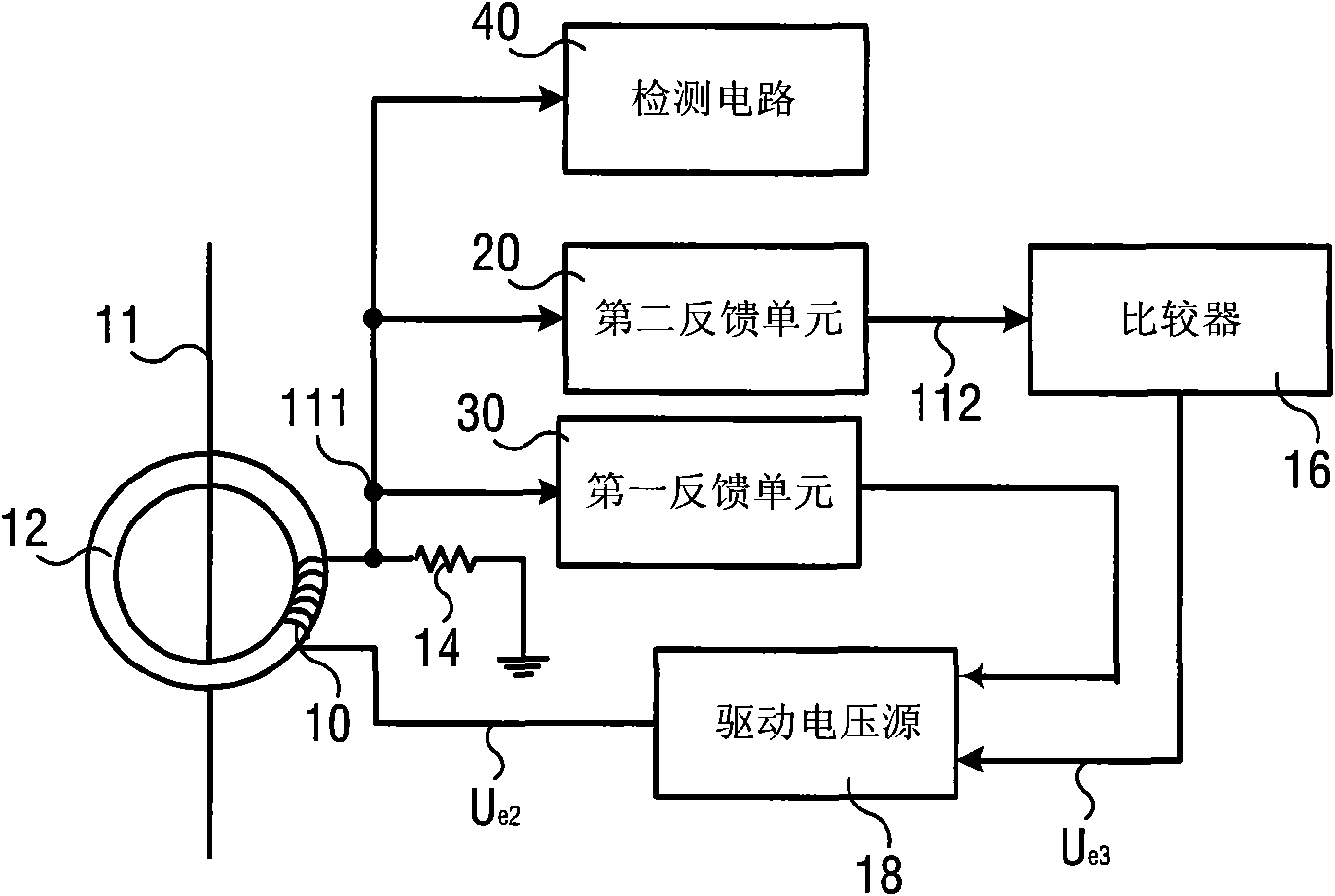

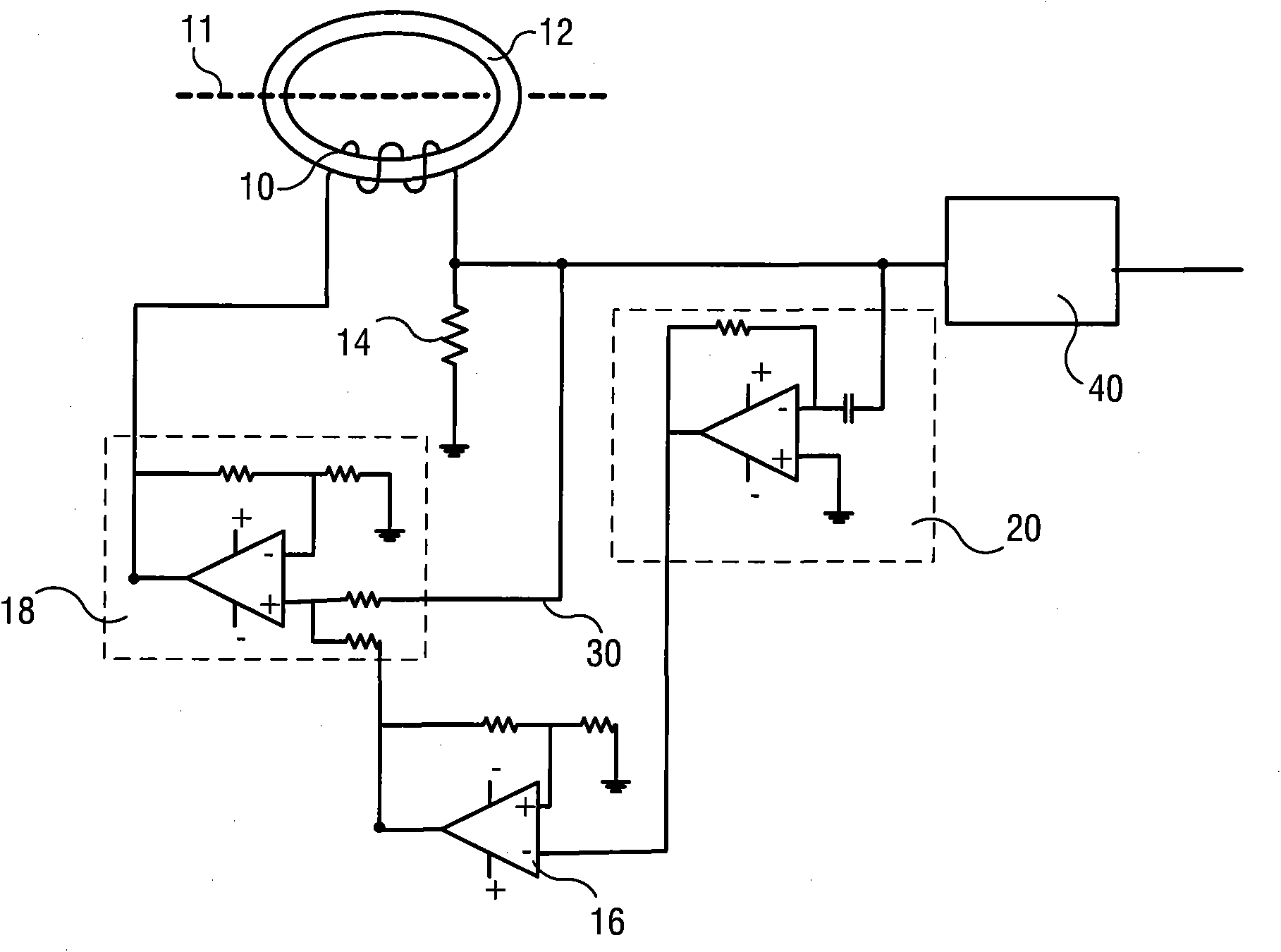

[0029] figure 2 In an exemplary embodiment of the current measuring device of the present invention, it includes a magnetic ring 12 , a coil 10 , a sampling resistor 14 , a driving voltage source 18 , a comparator 16 , a first feedback unit 30 and a second feedback unit 20 .

[0030] The conductor 11 that can pass the current to be measured (direct current or alternating current) passes through the magnetic ring 12, the coil 10 is wound on the magnetic ring 12, the sampling resistor 14 is connected in series with one end of the coil 10, the other end of the coil 10 is connected to the drive voltage source 18 The output terminal can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com