Power semiconductor with polysilicon structure at bottom of trench and method for manufacturing same

A technology for power semiconductors and manufacturing methods, which is applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., and can solve problems such as increasing manufacturing costs and increasing process complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

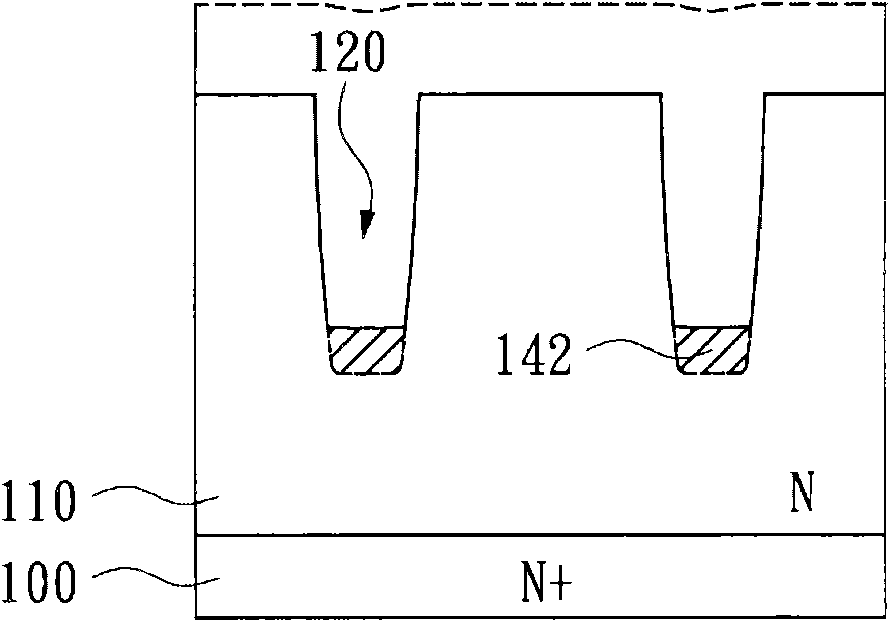

[0057] figure 2 It is the second embodiment of the manufacturing method of the trench power semiconductor of the present invention. Different from the first embodiment of the present invention, this embodiment does not remove the hard mask layer 125 after the step of forming the trench 120 by using the hard mask layer 125, but directly deposits the polysilicon layer and etching step. The hard mask layer 125 covering the upper surface of the epitaxial layer 110 helps to prevent the epitaxial layer 110 from being simultaneously etched away during the step of etching and removing the polysilicon material.

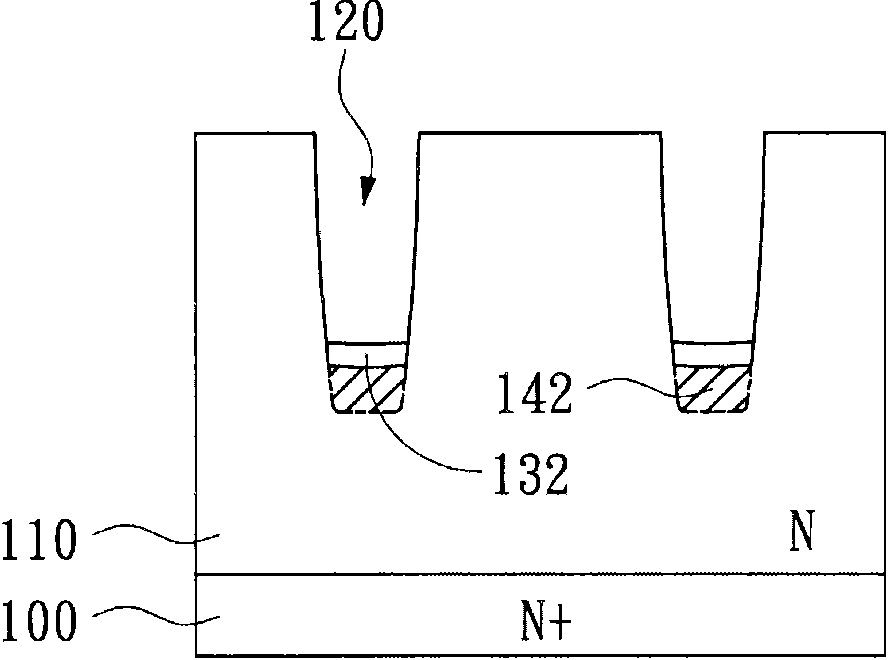

[0058] Figure 3A and Figure 3B It is the third embodiment of the manufacturing method of the trench power semiconductor of the present invention. like Figure 1G As shown, in the first embodiment of the present invention, the lower surface of the heavily doped polysilicon structure 142 is directly in contact with the epitaxial layer 110 . In contrast, if Figure 3A A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com