Sensorless induction motor control device having function of correcting slip frequency of motor

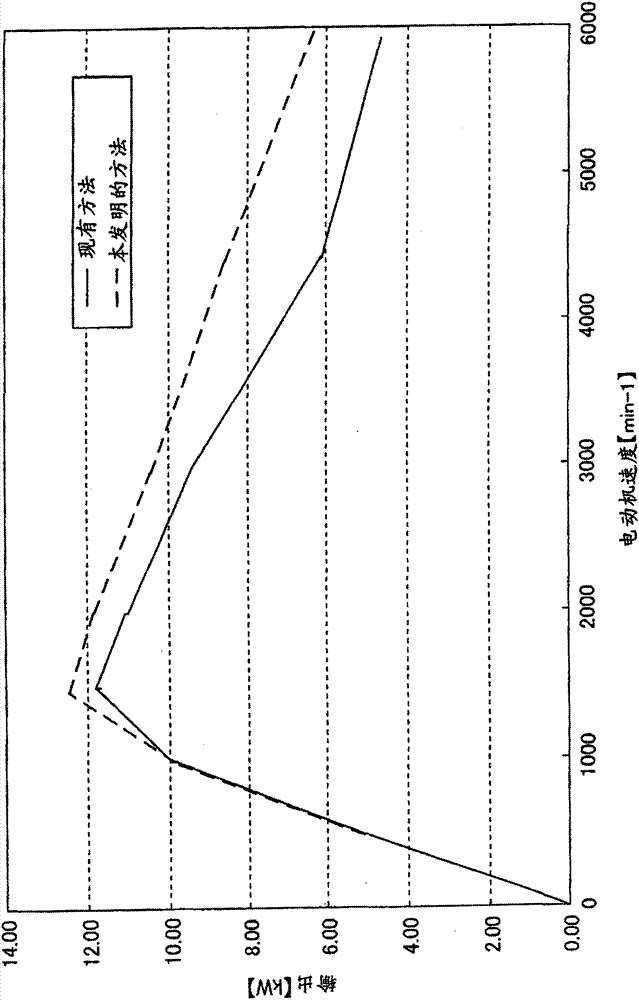

A technology of induction motor and slip frequency, applied in four-quadrant motor control, motor generator control, AC motor control and other directions, can solve the problems of low voltage command, the motor can not output output, no flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

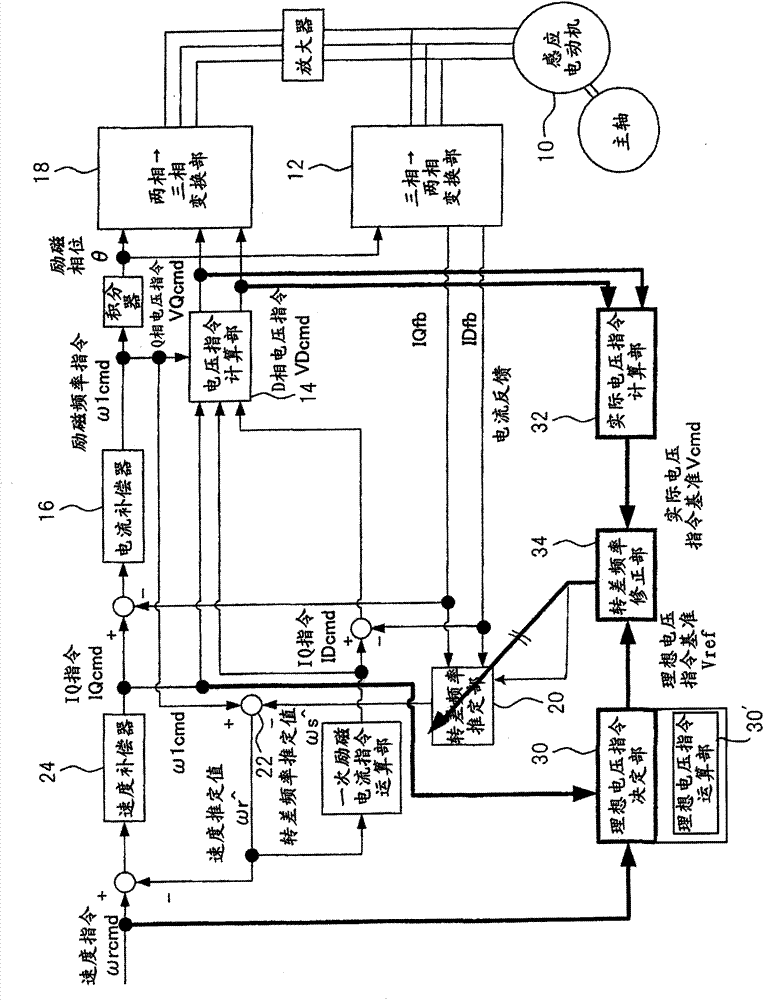

[0017] Embodiments of the present invention will be described in detail below with reference to the drawings. In the drawings, the same reference numerals are given to the same components.

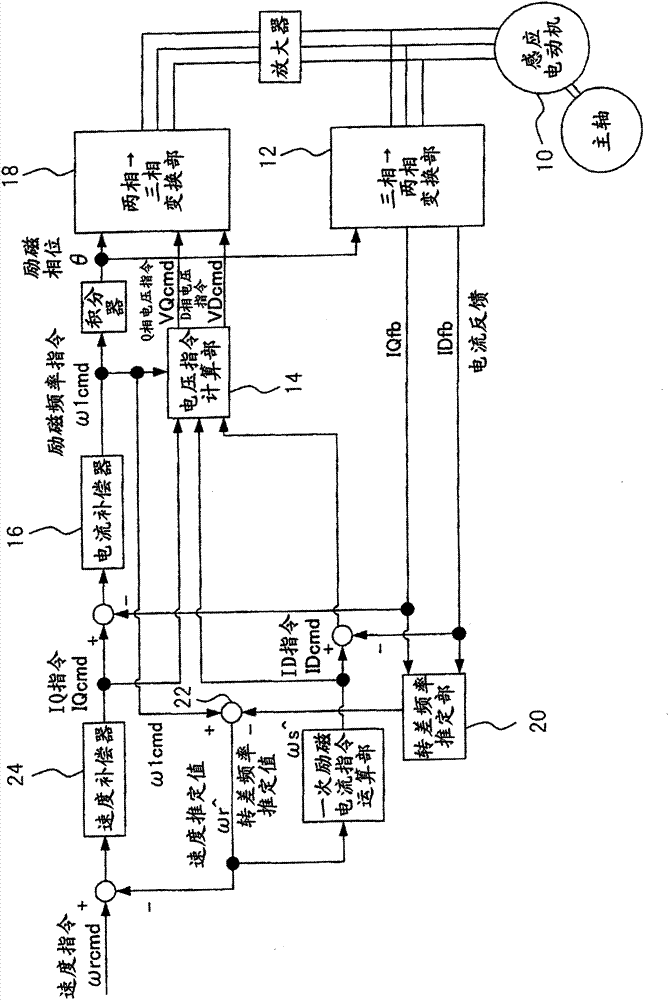

[0018] With reference to the accompanying drawings, figure 2 It is a block diagram showing a sensorless induction motor control device having a slip frequency correction function according to the first embodiment of the present invention.

[0019] In vector control, the slip frequency ω s It has the following relationship with D-phase current ID and Q-phase current IQ.

[0020] ω s = R 2 / L 2 ·IQ / ID (1)

[0021] Among them, R 2 is the secondary resistance, L 2 is the secondary reactance. Also, if the motor speed is set to ω r , then the excitation frequency ω1 is:

[0022] ω1=ω r +ω s (2)

[0023] The relationship between D-phase voltage VD and Q-phase voltage VQ and ID, IQ, ω1 is as follows:

[0024] VD=R 1 ·ID-σ·L 1 ·ω1·IQ (3)

[0025] VQ=R 1 ·IQ+L 1 ·ω1·ID (4) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com