Side airbag device for vehicle

An airbag device and airbag technology are applied in the directions of vehicle safety arrangement, pedestrian/occupant safety arrangement, vehicle components, etc., which can solve the problem of difficulty in ensuring the thickness of the airbag, and achieve the effect of simple structure and easy production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

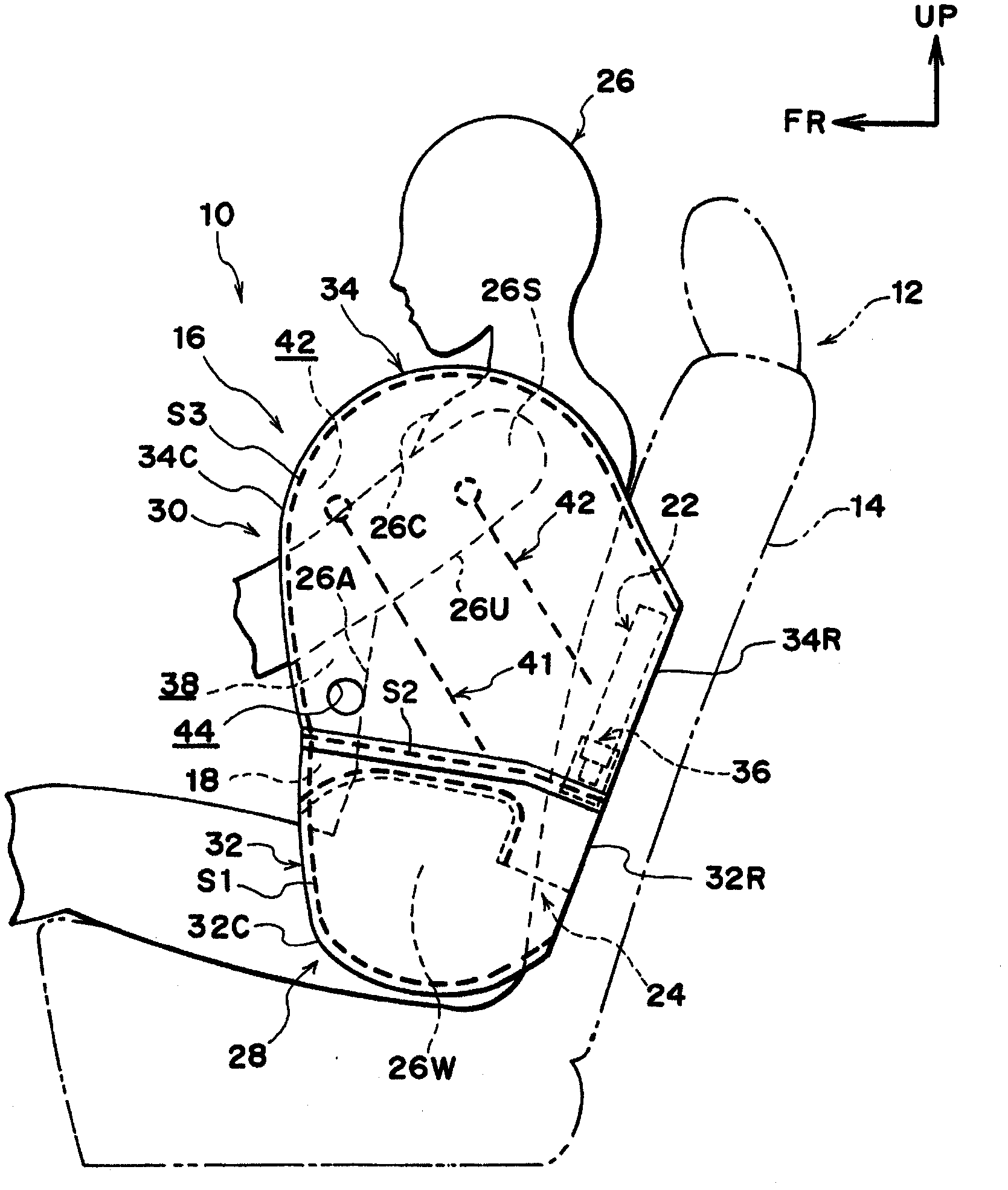

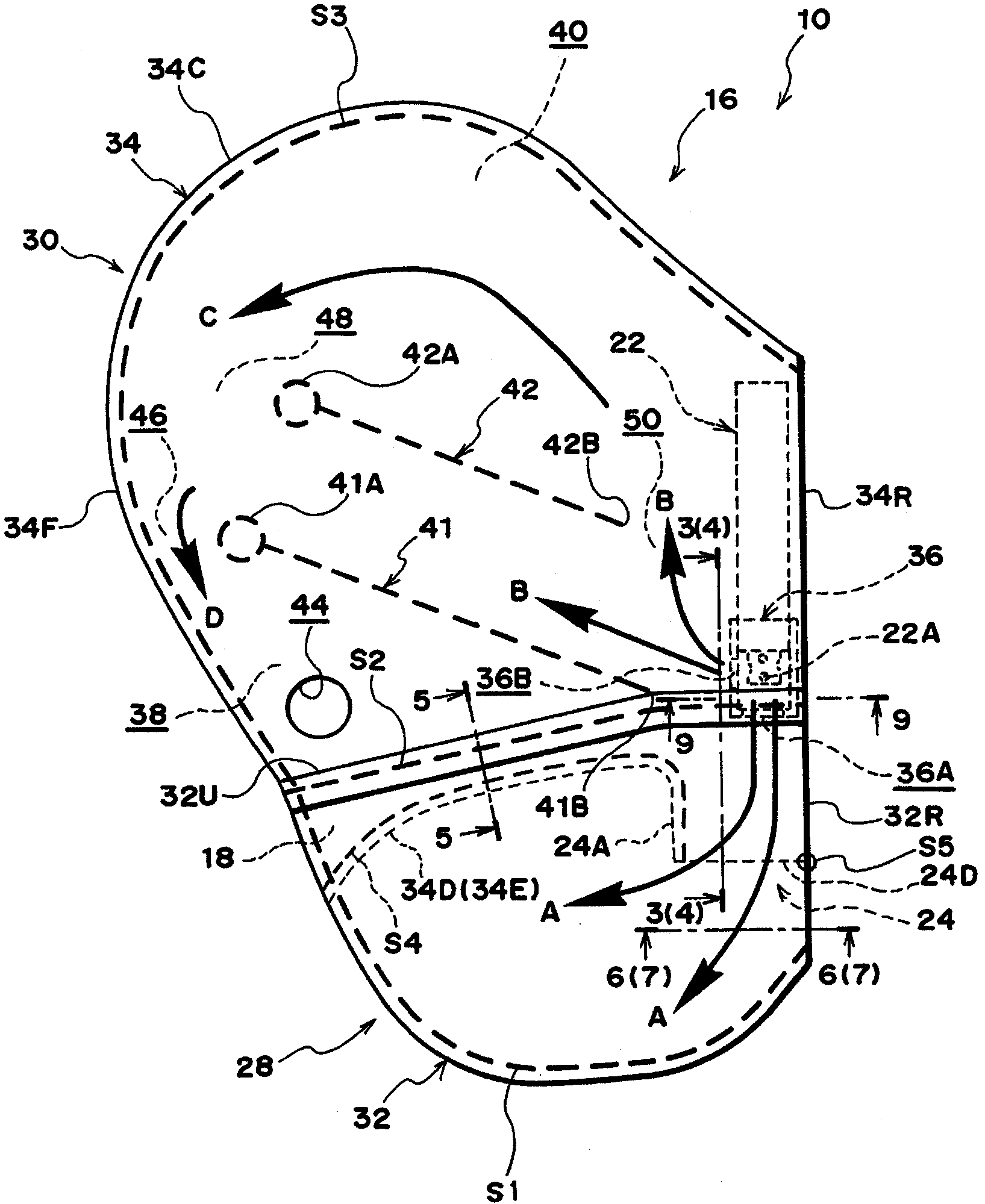

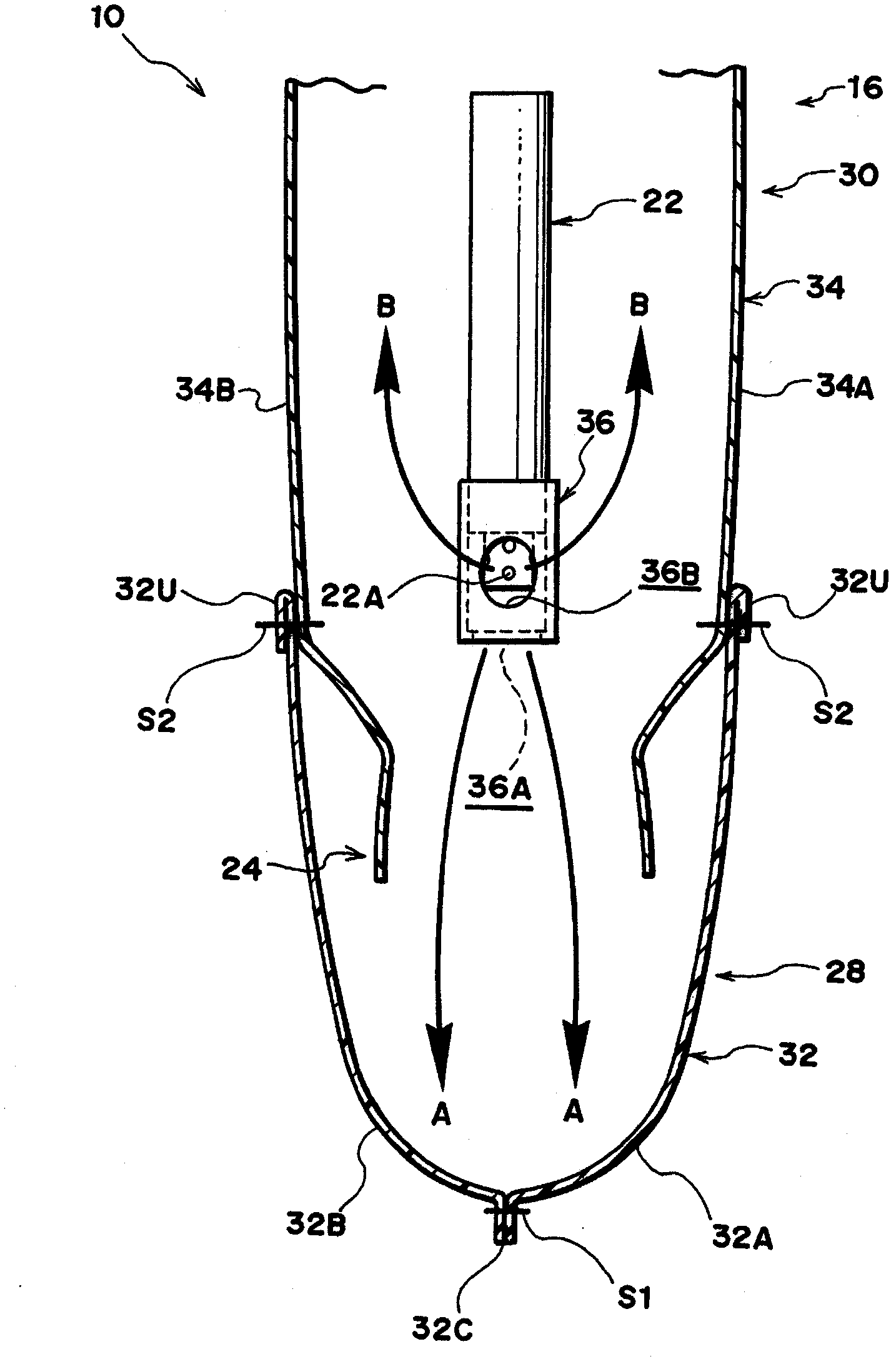

[0113] exist Figure 1 to Figure 3 Among them, the side airbag device 10 for a vehicle in this embodiment relates to a side airbag device mounted, for example, on the side of the seat back 14 of the seat 12 for a vehicle, and the side airbag device 10 for a vehicle has a side airbag. Air bag 16 , partition wall 18 , inflator 22 and check valve 24 .

[0114] The side airbag 16 is configured to receive gas supplied from the inflator 22 in the event of a side collision, and to inflate and expand on the side of the occupant 26 seated on the vehicle seat 12 . The lower chamber 28 , which is an example of a high-pressure chamber, becomes a high-pressure side during expansion and deployment, and the upper chamber 30 , an example of a low-pressure chamber, which is a lower pressure than the high-pressure chamber. The side airbag 16 is configured such that the lower chamber 28 and the upper chamber 30 are each inflated and deployed when a side collision occurs.

[0115] The lower cha...

no. 2 Embodiment approach

[0172] refer to Figure 18 , in the vehicle side airbag device 20 according to the present embodiment, in the side airbag 16 in the inflated and deployed state, the check valve 24 is formed by the rear end portion 18R of the partition wall 18 and the rear side of the side airbag 16 . The surface 16R is formed, and is configured such that the flow path of the gas is opened by separating the rear end portion 18R of the partition wall 18 from the rear inner surface 16R; The flow path of the gas is closed.

[0173] This embodiment is formed, for example, by folding one base fabric 60 in two toward the seat front side with the seat rear end 60R as the center, and Figure 19 As shown, the outer base fabric 60A located outside in the seat width direction and the inner base fabric 60B located inside in the seat width direction are sewn at the peripheral edge portion 60C (sewn portion S6 ). The partition wall 18 is constituted as a separate part from the side airbag 16, and is sewn t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com