Oil-fume separator based on diversion at 360 degrees

An oil fume separator and high-level technology, which is applied in the field of 360-degree diversion oil fume separators, can solve the problems of affecting the suction effect of a range hood, a small collision probability between oil molecules and a separation plate, and irregular airflow passages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

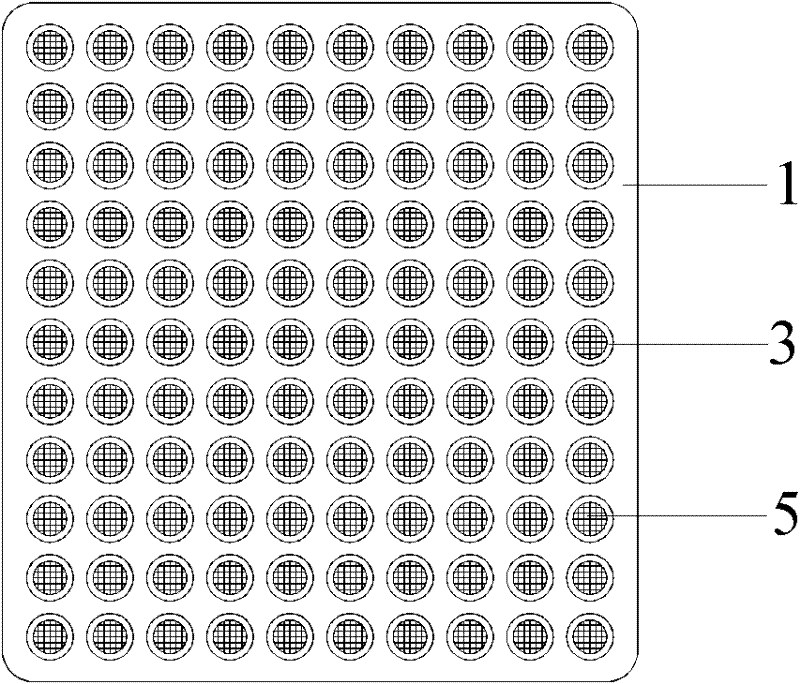

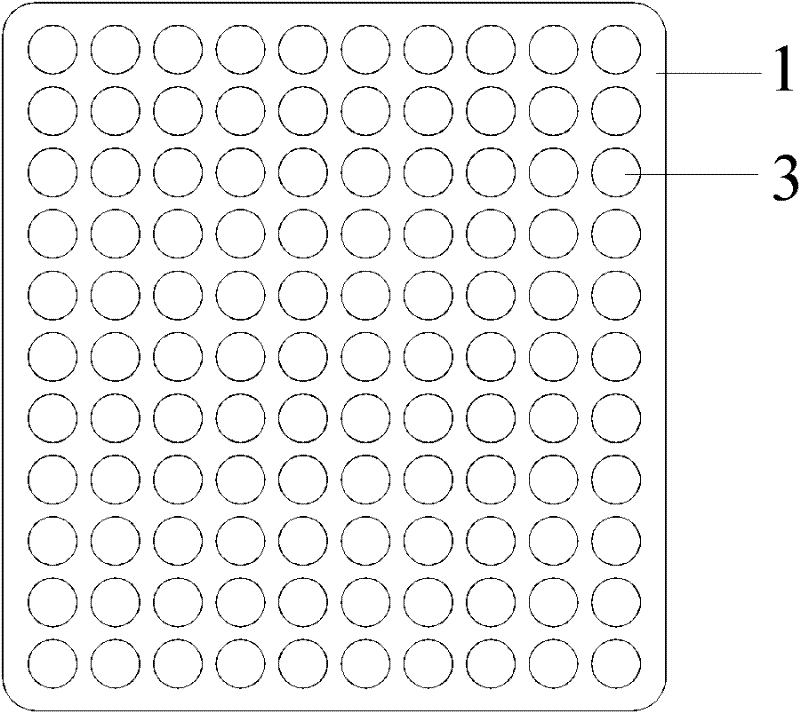

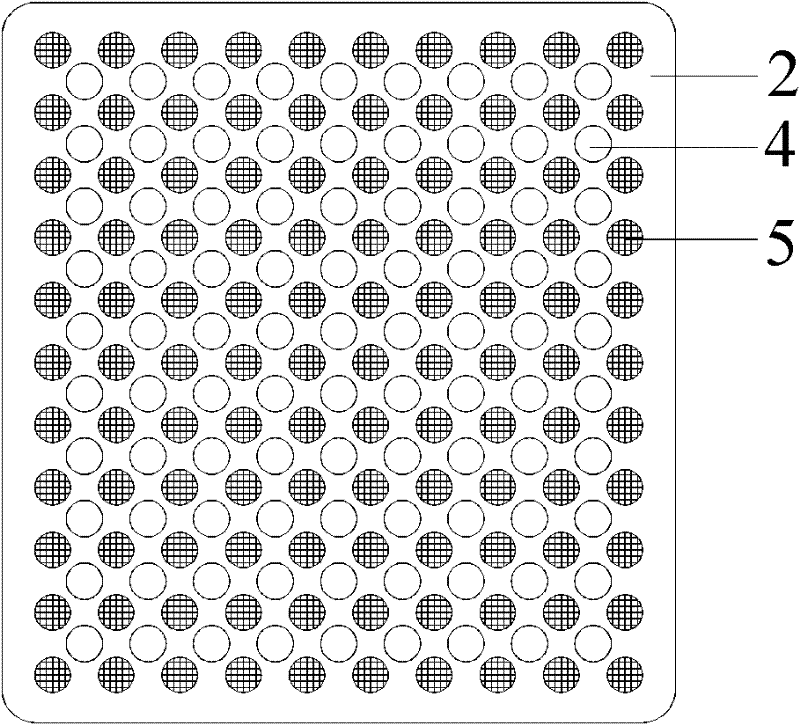

[0032] See Figure 1-Figure 4 , figure 1 It is a top view structure diagram of the 360-degree direction guide oil fume separator in embodiment 1; figure 2 It is a schematic structural view of the front plate of the 360-degree direction oil fume separator in embodiment 1; image 3 It is a schematic structural view of the back plate of the 360-degree direction oil fume separator in embodiment 1; Figure 4 It is a schematic cross-sectional structure diagram of the 360-degree direction guide oil fume separator in Example 1.

[0033] The 360-degree direction guide oil fume separator provided in this embodiment is composed of a front plate 1 and a rear plate 2, wherein a certain distance is set between the front plate 1 and the rear plate 2, and the front plate 1 is provided with an air intake The openings 3 are all circular and arranged alternately, and the edge of the air inlet 3 is set with a flange 6 of a certain height; the rear plate 2 is provided with an air outlet 4, whi...

Embodiment 2

[0037] See Figure 5 , which is a top view structural diagram of the 360-degree direction guide oil fume separator in Example 2.

[0038] In the 360-degree direction diversion oil fume separator provided in this embodiment, the air intake holes 3 of the front plate 1 are set as hexagonal holes, and the air intake holes 3 are arranged in parallel and alternate rows, and alternately arranged in columns. The air intake holes 3 of the front plate are honeycomb-shaped, and can also be arranged in parallel. The protrusion 5 corresponding to the air intake hole of the front plate on the rear plate 2 can be set as a hexagonal column, or as a spherical protrusion, and the oil filtering channel and oil fume separation effect will not change.

Embodiment 3

[0040] See Image 6 , which is a top structural schematic diagram of the 360-degree direction guide oil fume separator in Example 3.

[0041] In the 360-degree direction guide oil fume separator provided in this embodiment, the air intake holes 3 of the front plate 1 are arranged in a long strip shape and arranged in parallel with each other, and the protrusions 5 on the rear plate 2 corresponding to the air intake holes of the front plate can be set as The same shape of the elongated column, the oil filter channel and oil fume separation effect will not change.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com