Synchronous supporting plate jacking device of moving workbench of pressing machine

A technology of moving worktable and synchronizing device, applied in the field of presses, can solve the problems of inconsistent action of hydraulic cylinders, tilting of pallets, etc., and achieve the effects of reducing workload, running smoothly, and saving time and effort in assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

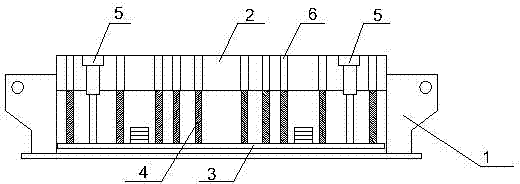

[0012] Such as figure 1 As shown, the worktable 2 is supported on the bench 1 of the workbench, and the supporting plate 3 is arranged at the lower part of the bench 1 of the workbench, that is, the lower part of the working table, and the supporting plate 3 and the working table 2 are connected by a hydraulic cylinder 5. The ejector pin 4 is arranged on the plate, and the ejector pin hole 6 is arranged on the working table corresponding to the ejector pin. After the stamping is completed, the hydraulic cylinder 5 drives the supporting plate 3 to move upward, and the ejector pin 4 penetrates the ejector pin hole 6 and inserts it into the lower mold. The stamping parts are ejected.

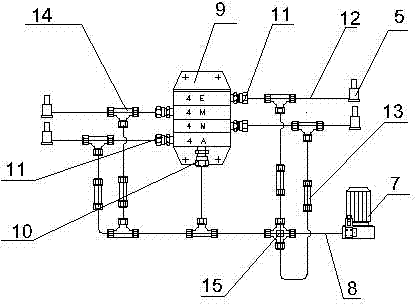

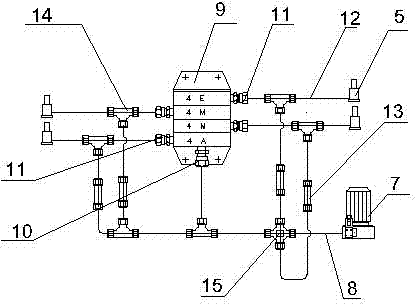

[0013] Such as figure 2 As shown, the driving hydraulic oil of the hydraulic cylinder 5 is supplied by the oil outlet 11 of the progressive distributor. In this embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com