Solventless releaser composition for use with silicone pressure-sensitive adhesives and release liner

A release agent and composition technology, which is applied in the field of solvent-free release agent composition, can solve the problems of pinholes, shrinkage, and peeling on the coating surface, and achieve the effect of improving the release performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

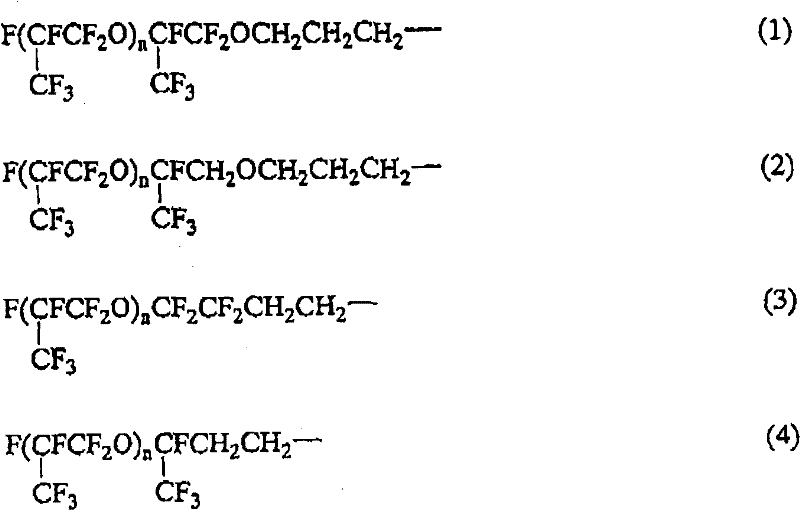

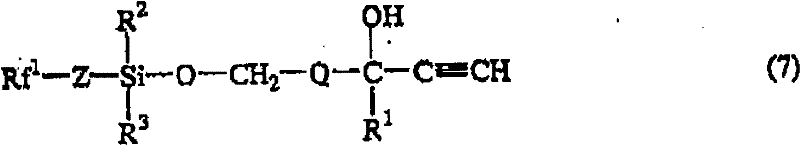

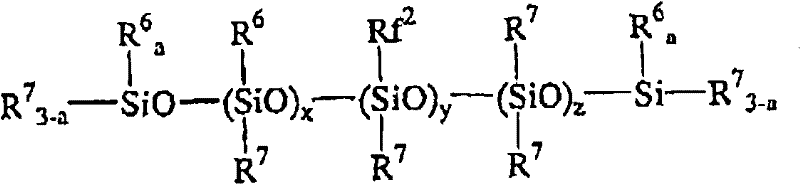

Method used

Image

Examples

Embodiment 1

[0077] By adding 95.3 parts of organopolysiloxane (alkenyl content 0.0034mol / 100g, fluorine content 44.0wt%, viscosity 1080mPa·s) containing alkenyl and fluorinated substituent groups having formula (I), formula ( Ⅲ) organohydrogenpolysiloxane (fluorine content 37.3wt%) (providing Si-H group / Si-CH=CH 2Composition #1 was prepared by uniformly mixing 4.7 parts of the group molar ratio of 2.5) and 0.65 parts of the reaction regulator having the formula (IV). To the mixture was added an amount of chloroplatinic acid-vinylsiloxane complex salt to provide 50 ppm of platinum. The resulting composition #1 had a viscosity of 980 mPa·s.

[0078]

Embodiment 2

[0080] By adding 86.4 parts of organopolysiloxane (alkenyl content 0.0109mol / 100g, fluorine content 38.8wt%, viscosity 288mPa·s) containing alkenyl and fluorinated substituents having formula (II) and formula (III) Organohydrogenpolysiloxanes (providing Si-H groups / Si-CH=CH 2 Composition #2 was prepared by uniformly mixing 13.6 parts with a group molar ratio of 2.5) and 0.65 parts of a reaction modifier having the formula (IV). To the mixture was added an amount of chloroplatinic acid-vinylsiloxane complex salt to provide 50 ppm of platinum. The resulting composition #2 had a viscosity of 300 mPa·s.

[0081]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com