Aluminum electrolytic tank anode carbon block of irregularly-shaped structure with exhaust passage and preparation method thereof

A technology of anode carbon block and exhaust channel, which is applied in the field of aluminum electrolysis, can solve the problems of ineffective current efficiency and power consumption of the electrolytic cell, and achieve the effects of benefiting the current efficiency, avoiding shedding phenomenon, and reducing the voltage of the cell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

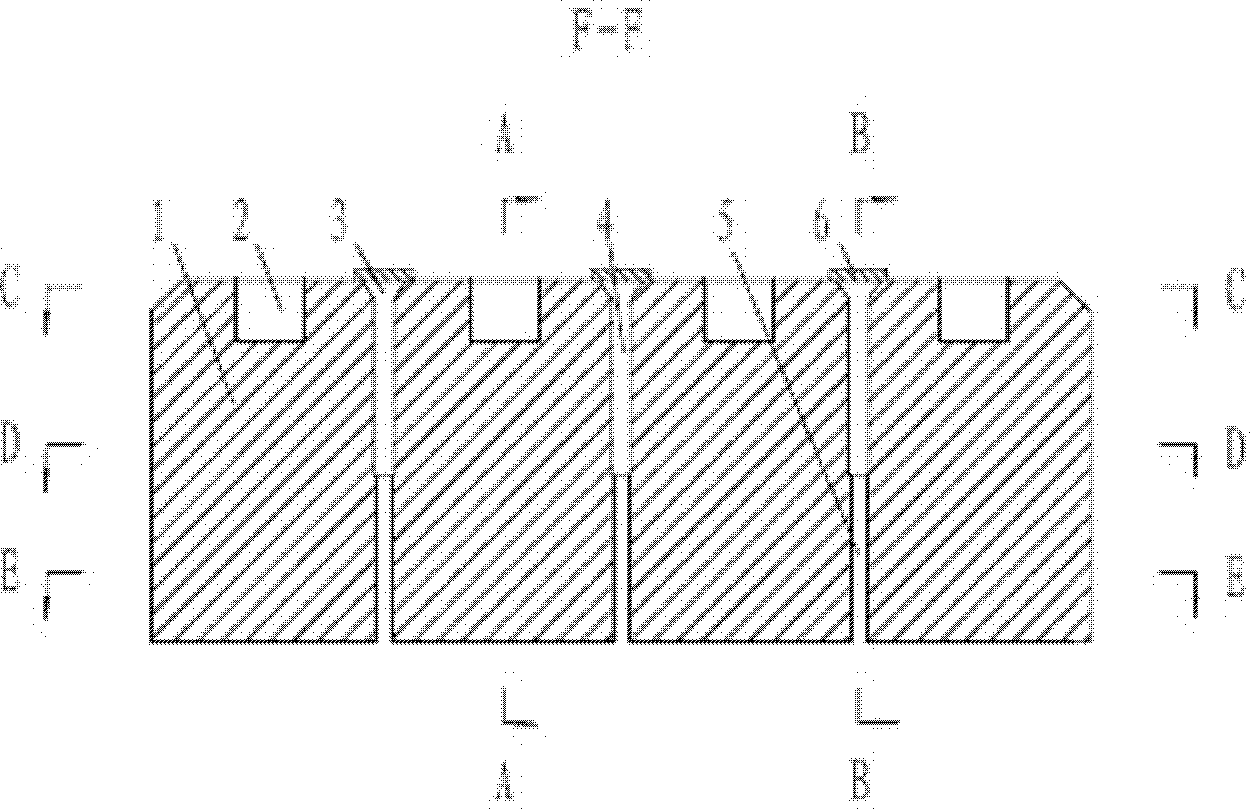

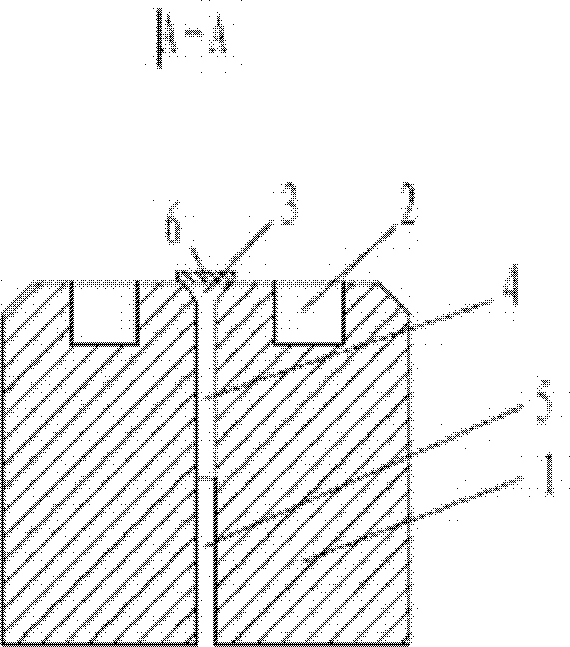

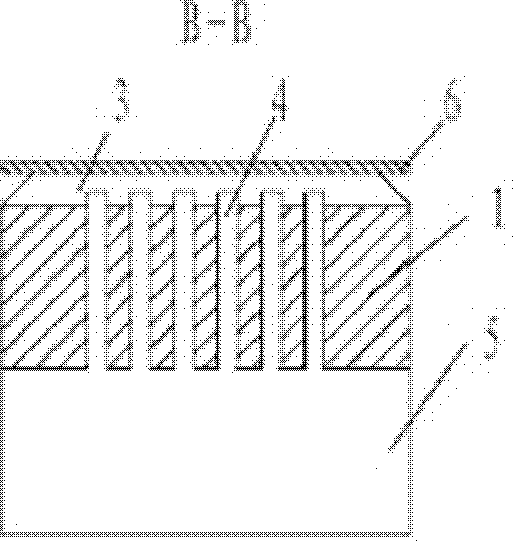

[0084] The cross-sectional structure of the anode carbon block of the special-shaped aluminum electrolytic cell with the exhaust channel is as follows: figure 1 As shown, the A-A surface structure is as figure 2 As shown, the B-B surface structure is as image 3 As shown, the C-C surface structure is as Figure 4 As shown, the D-D surface structure is as Figure 5 As shown, the E-E surface structure is as Figure 6 As shown; the top edge of the anode carbon block 1 is provided with chamfers, and there are two rows of carbon bowls evenly distributed on the top surface, and each row of carbon bowls is arranged longitudinally along the anode carbon block, and is composed of four carbon bowls 2; There is a groove 3 between them, and the bottom of the groove is provided with a through hole 4 communicating with the groove 5 at the bottom of the anode carbon block; a cover plate 6 is arranged above the groove;

[0085] A horizontal groove is provided between two adjacent carbon ...

Embodiment 2

[0097] The cross-sectional structure of the anode carbon block of the special-shaped aluminum electrolytic cell with the exhaust channel is as follows: Figure 7 As shown, the A-A surface structure is as Figure 8 As shown, the B-B surface structure is as Figure 9 As shown, the C-C surface structure is as Figure 10 As shown, the D-D surface structure is as Figure 11 As shown, the E-E surface structure is as Figure 12 As shown; the top edge of the anode carbon block 1 is provided with chamfers, and a row of carbon bowls is evenly distributed on the top surface and arranged longitudinally along the anode carbon block. A row of carbon bowls is composed of four carbon bowls 2; There is a groove 3, and a through hole 4 is provided at the bottom of the groove to communicate with the groove 5 at the bottom of the anode carbon block; a cover plate 6 is provided above the groove;

[0098] A transverse groove is provided between two adjacent carbon bowls; each groove is provided w...

Embodiment 3

[0109] The cross-sectional structure of the anode carbon block of the special-shaped aluminum electrolytic cell with the exhaust channel is as follows: Figure 13 As shown, the A-A surface structure is as Figure 14 As shown, the B-B surface structure is as Figure 15 As shown, the C-C surface structure is as Figure 16 As shown, the D-D surface structure is as Figure 17 As shown, the E-E surface structure is as Figure 18 As shown; the structure is the same as in Embodiment 1, the difference is that two through holes are provided on the transverse groove to communicate with the corresponding groove, and one through hole is provided on the longitudinal groove to communicate with the corresponding groove;

[0110] The height of the top surface of the groove from the top of the anode carbon block is 20-50cm, and the width of the groove is 2.5-3.5cm;

[0111] The cross section of the groove is an inverted triangle, the height is 3-10 cm, and the width of the top surface is 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com