Automatic pressing pump test device

A test device and automatic technology, which is applied in pump testing, machine/engine, liquid displacement machinery, etc., can solve the problems of damage to the surface quality of the paint, great influence on the sealing reliability of joints, and high labor intensity, etc., to achieve sealing pressure Appropriate and reliable tightening force, low labor intensity and high sealing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

The present invention will be further described below in conjunction with the accompanying drawings of the description.

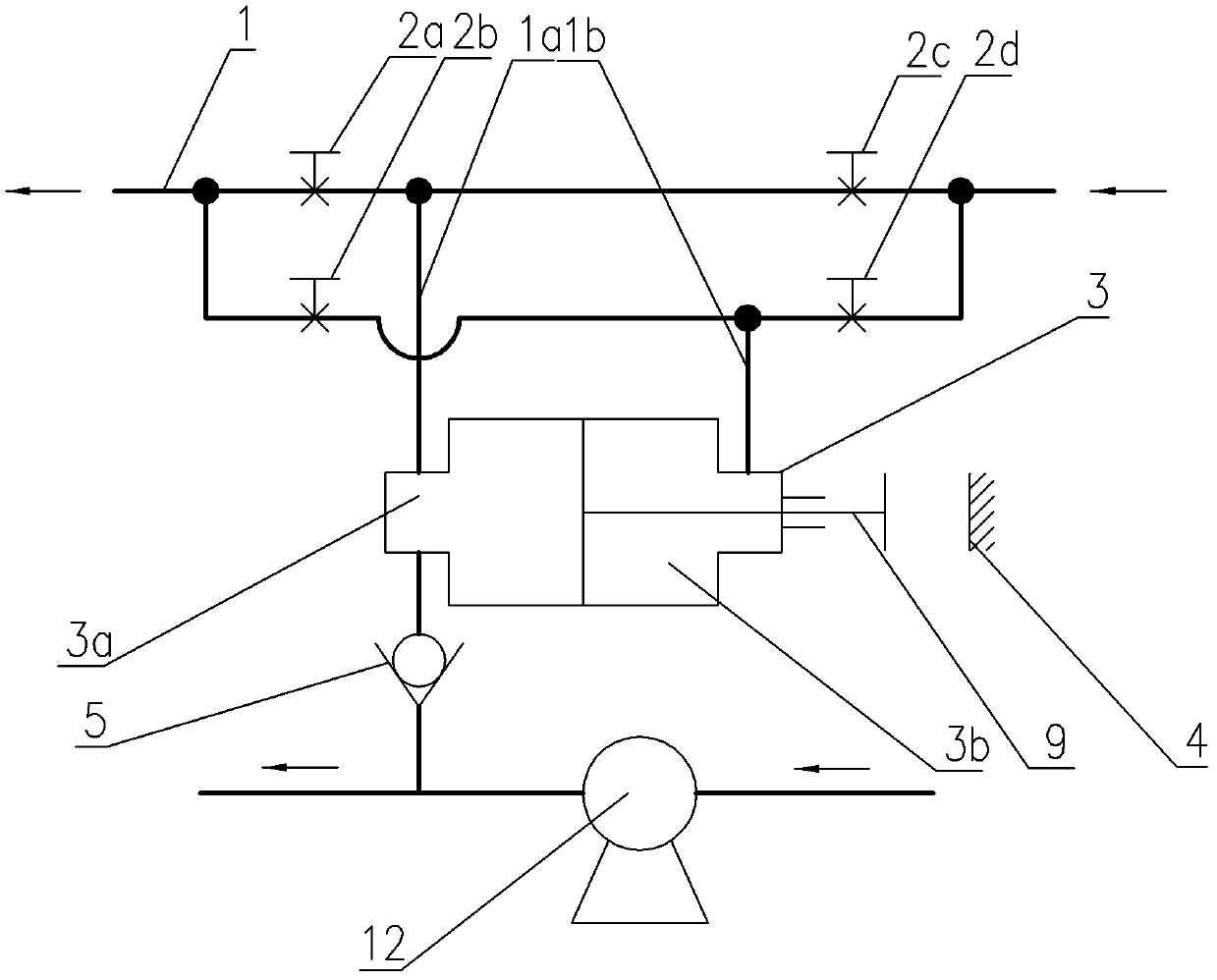

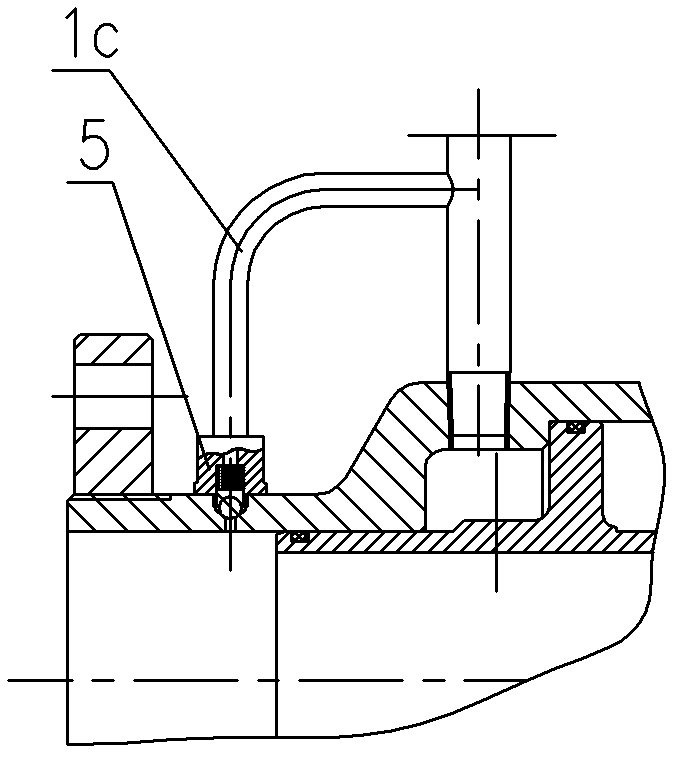

Automatic compression pump test device of the present invention, such as figure 1 As shown, it has a mounting seat 6, on which the suction pipe part and the discharge pipe part are installed, and a placement platform 6a is left between the suction pipe part and the discharge pipe part (it is better to set the placement platform 6a so that it can be adjusted up and down) for Place the tested pump 12; the suction pipe parts include the suction flange pipe 14 fixed on the mounting base 6 and the suction sealing disc 13 assembled on one end of the suction flange pipe 14 (the connection between the suction flange pipe 14 and the suction sealing disc 13 is detachable form, shown as a threaded connection);

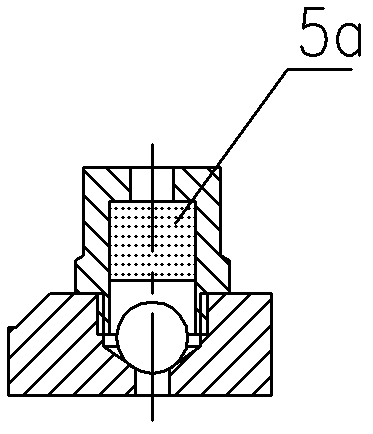

The discharge pipe parts include a cylinder block 8 with an axial through hole fixed on the mounting seat 6, an axial channel 9a (the diameter of the axial chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com