Mechanical transmission automatic shift system used for electromobile

A technology for electric vehicles and automatic shifting, which is applied in the direction of mechanical equipment, transmission control, and components with teeth, etc., can solve the problems affecting the driving performance and comfort of electric vehicles, and the complex operation of manual transmission shifting, etc., to achieve good results Fuel-saving effect, reduced labor intensity, and simplified complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

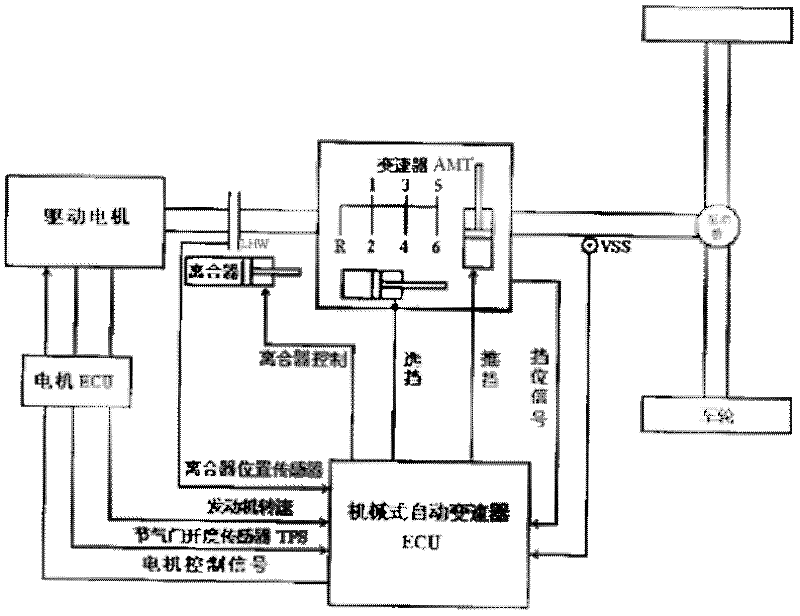

[0009] The invention provides an automatic shifting system of a mechanical transmission for an electric vehicle. Describe below in conjunction with accompanying drawing.

[0010] exist figure 1 In the schematic diagram of the mechanical transmission automatic shift system shown, the clutch and the transmission are connected in series between the drive motor and the drive axle, and the clutch position sensor LHW and its control mechanism are installed on the clutch, and the transmission is changed to an automatic mechanical transmission AMT. The vehicle speed sensor VSS is installed near the drive axle, and the motor ECU (electronic control unit) is connected to the mechanical automatic transmission ECU for electric vehicles, and the mechanical automatic transmission ECU is respectively connected to the clutch position sensor LHW and its control mechanism, the vehicle speed sensor VSS and the automatic mechanical transmission. Transmission AMT connection.

[0011] figure 1 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com