Drying and grading machine for processed object and drying and grading method

A technology of processed objects and classification methods, applied in dryers, drying solid materials, heating to dry solid materials, etc., can solve the problems of increased equipment cost, lack of classification function, reduced operability, etc., and achieve classification accuracy. Enhanced, reliable blowing effect, efficient drying and grading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Next, embodiments of the present invention will be described.

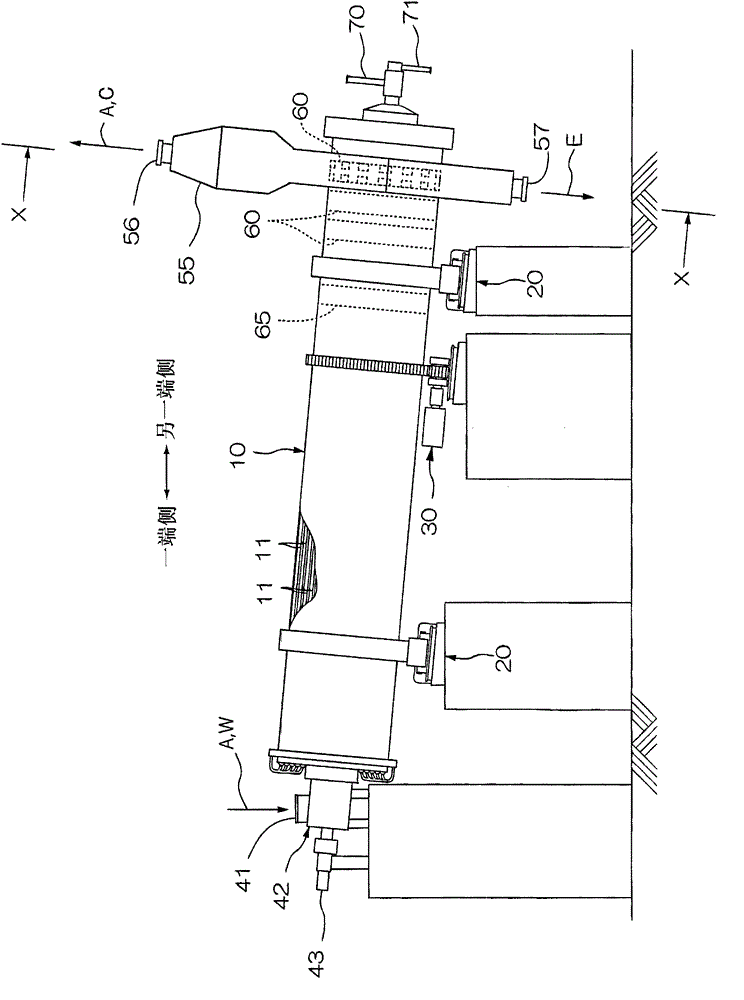

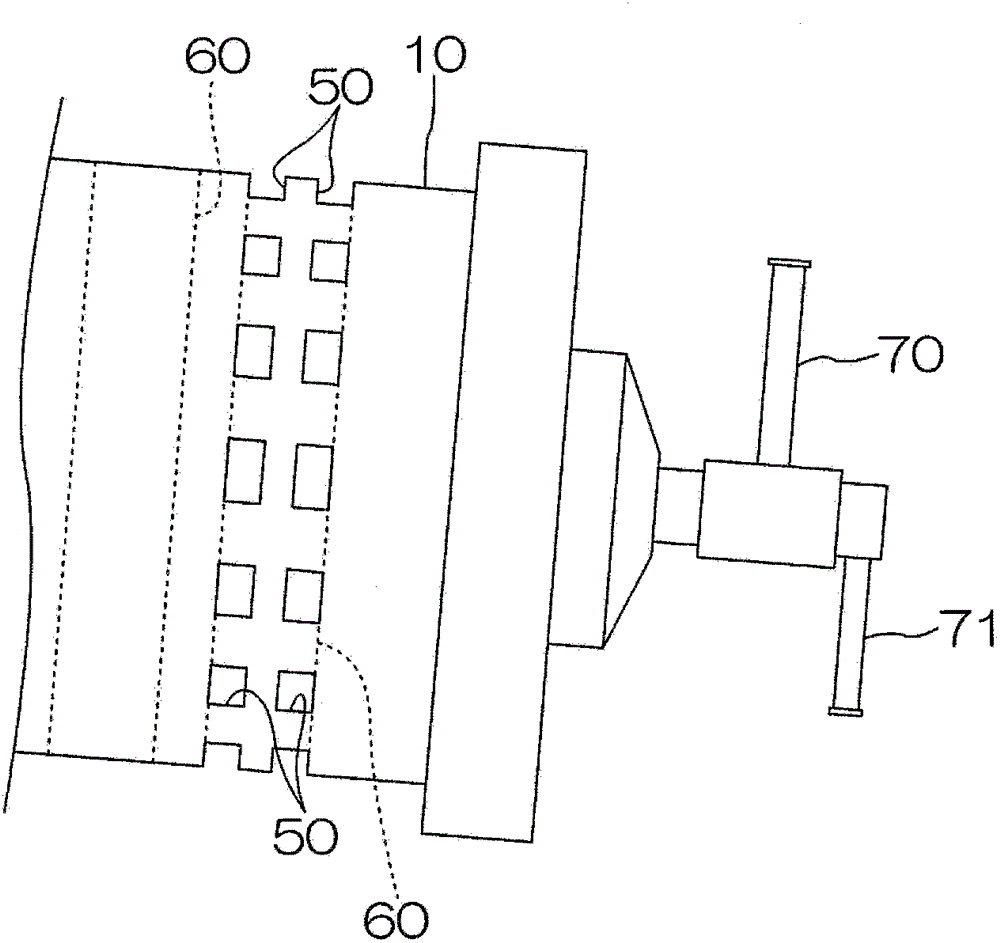

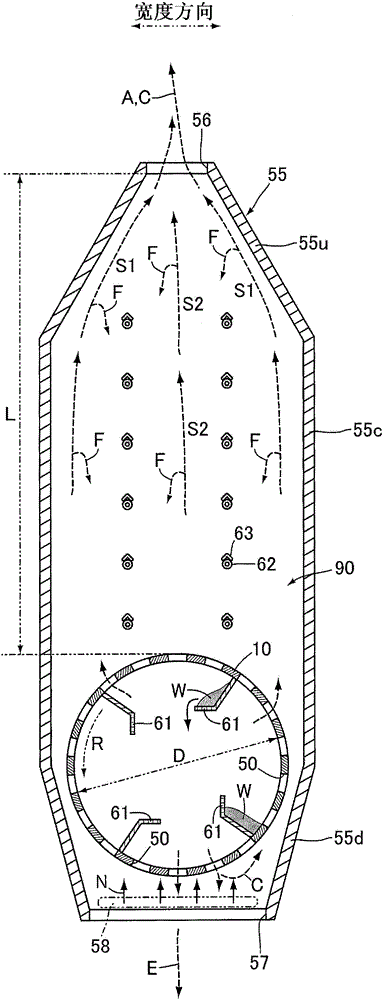

[0047] figure 1 The horizontal rotary dryer used for drying classification in this form is shown. This horizontal rotary dryer has a cylindrical rotary drum 10, the axis of which is slightly inclined relative to the horizontal plane, and one end of the rotary drum 10 is positioned higher than the other end. Below the rotating drum 10 , two support units 20 and a motor unit 30 are installed to support the rotating drum 10 , and the rotating drum 10 is rotatable around its own axis by the motor unit 30 . Such as image 3 As shown, the rotary drum 10 rotates in one direction, in the illustrated example, it rotates counterclockwise (in the direction of arrow R), and the rotational speed is, for example, less than 1 m / s.

[0048]Inside the rotating drum 10 , a plurality of steam pipes 11 are installed extending along the axial direction of the rotating drum 10 . The steam pipes 11 are metal pipes through whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com