Sealed connector and manufacture method thereof

A technology of connectors and contacts, which is applied in the parts, connections, and assembly/disassembly of contact parts of connection devices, which can solve the problems of high melting point and achieve the effect of wide range of materials, light weight and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

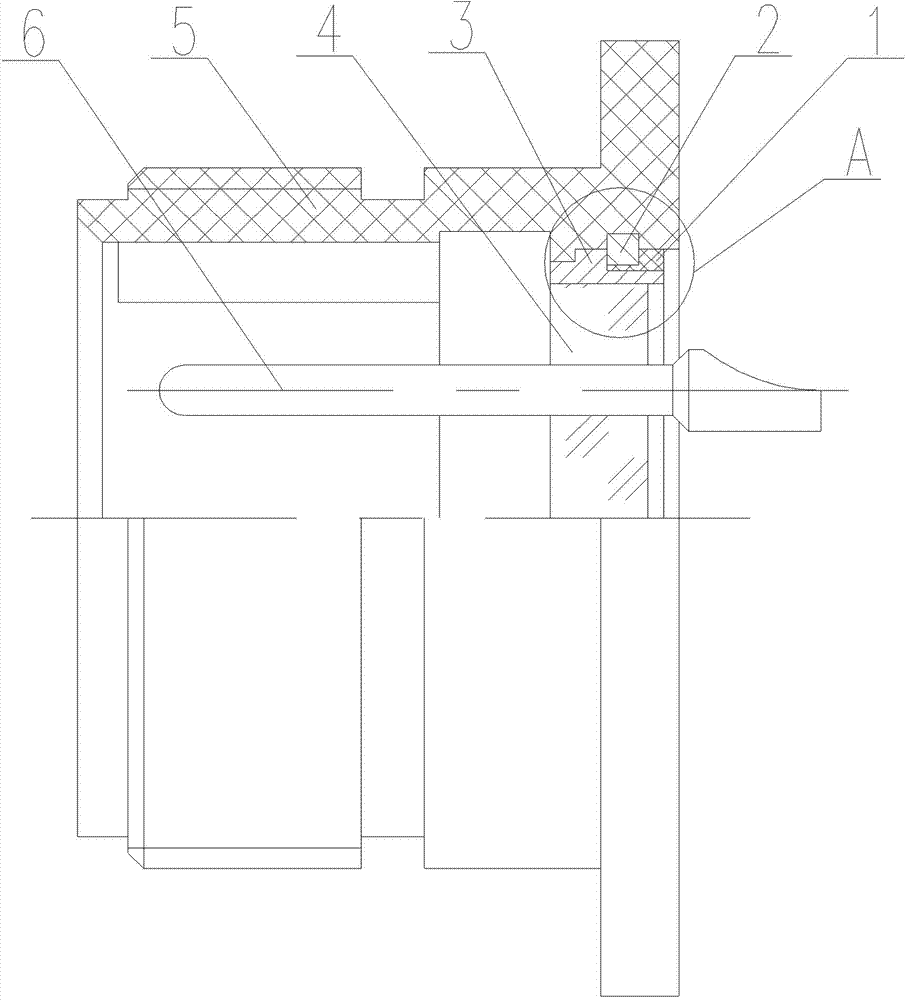

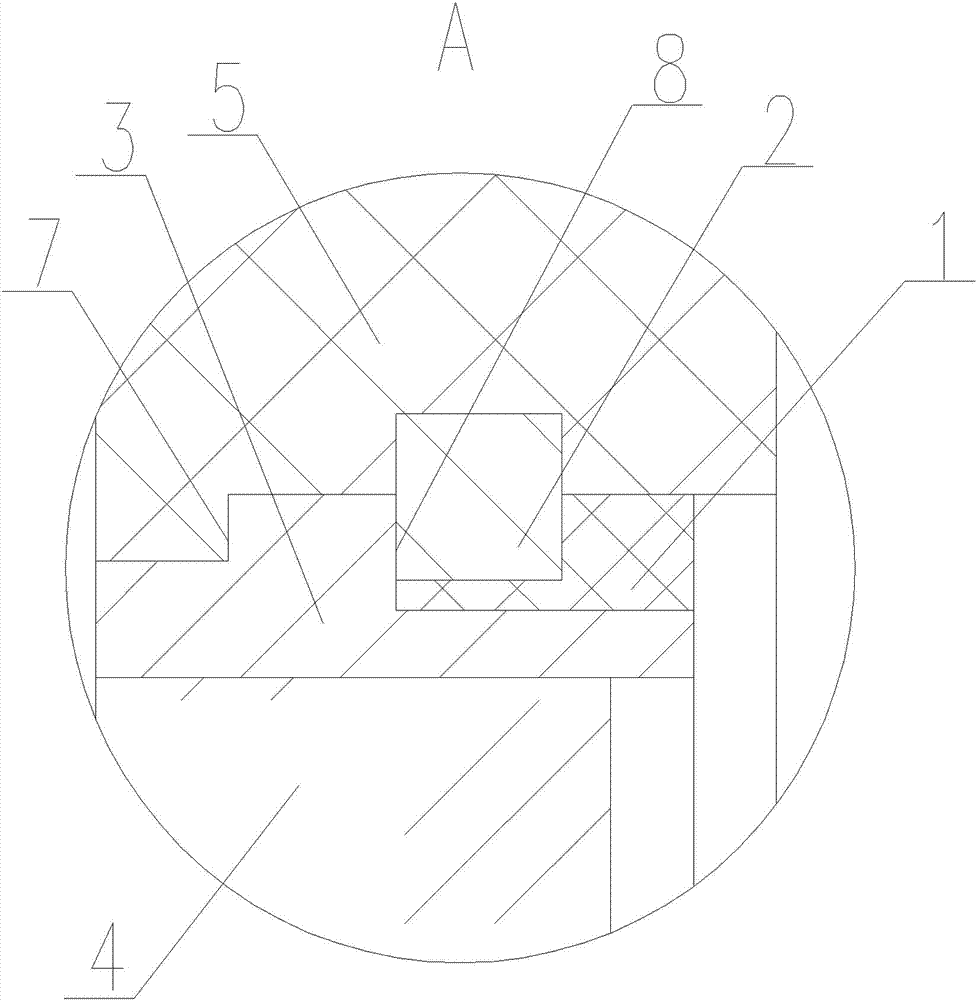

[0016] An embodiment of a sealed connector, in figure 1 and figure 2 Among them, the housing 5 is included, and the housing 5 has an inner hole running through the front and back, and a contact part is inserted in the inner hole of the housing 5. The contact part here includes a ring body 3, and the ring body 3 here is made of Made of high temperature resistant material, the degree of high temperature resistance of the ring body 3 is based on the temperature required for melting the glass powder. In the field of connectors, in order to obtain good sealing performance, sintered glass is used to sinter the contacts In the housing, the combination between the housing and the contact piece is good, and good sealing performance can be achieved. Sintered glass is made by sintering glass powder at high temperature. When making contacts with sintered glass as an insulator, fix the shell and contact in the mold according to the designed positional relationship and set the upper glass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com