Semi-open axial flow threshing cylinder

A threshing drum, semi-open technology, applied in threshing equipment, applications, agricultural machinery and tools, etc., can solve the problems of affecting the threshing effect, the threshing drum is easy to wrap and run grain, and the front end of the threshing drum has low linear speed, etc. Reach the effect of reducing the breakage rate, not easy to wrap and run grain, and reduce the breakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

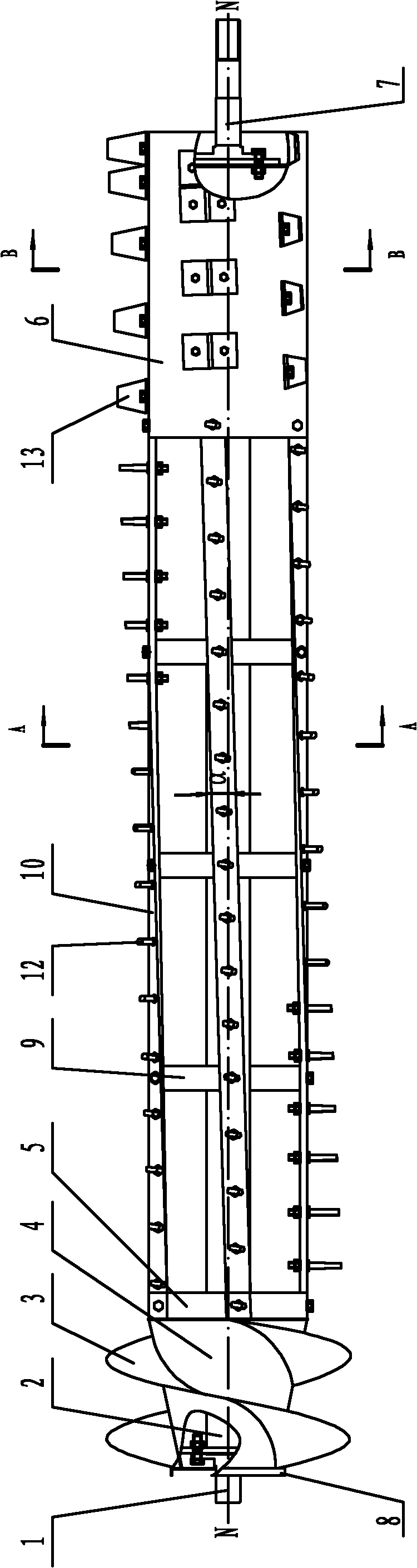

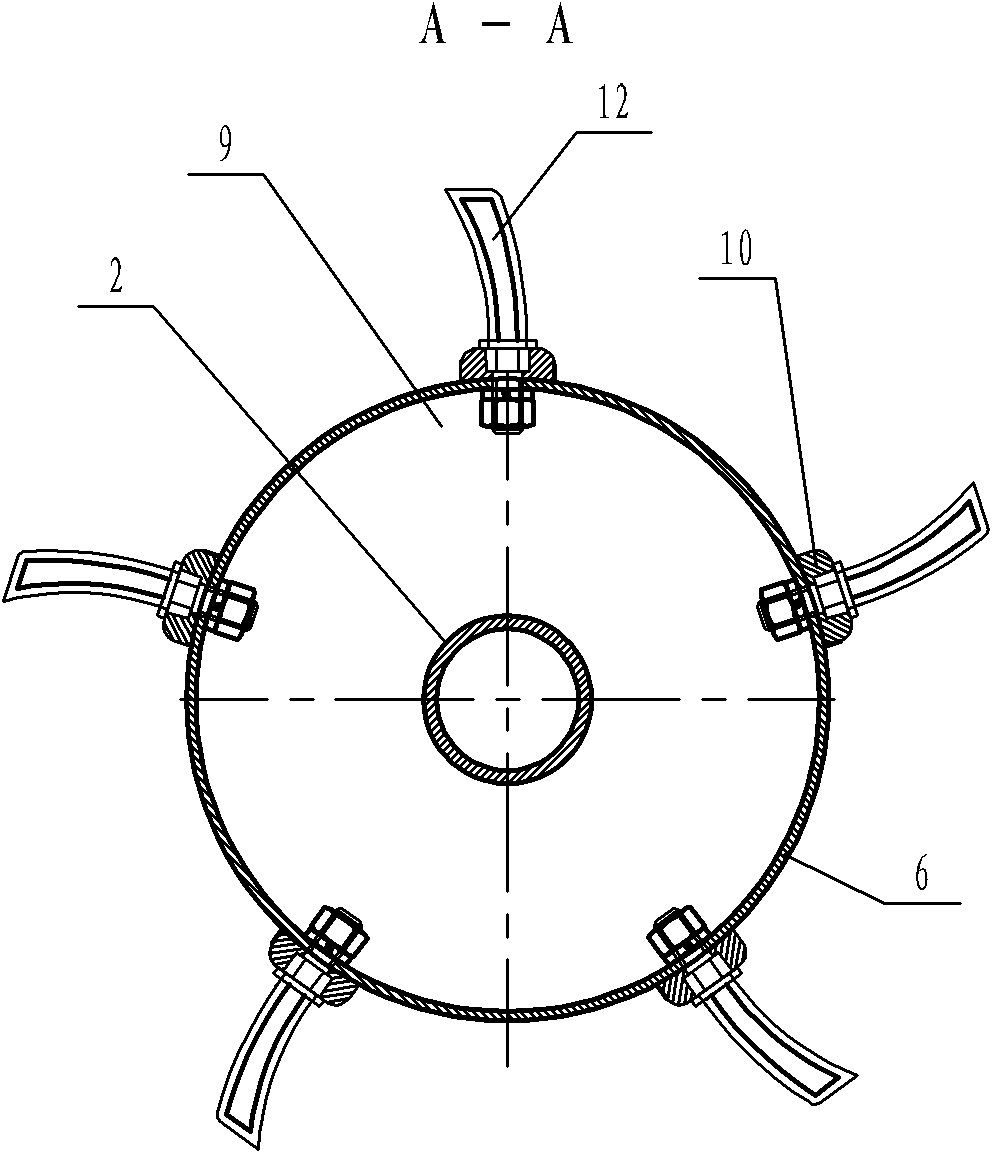

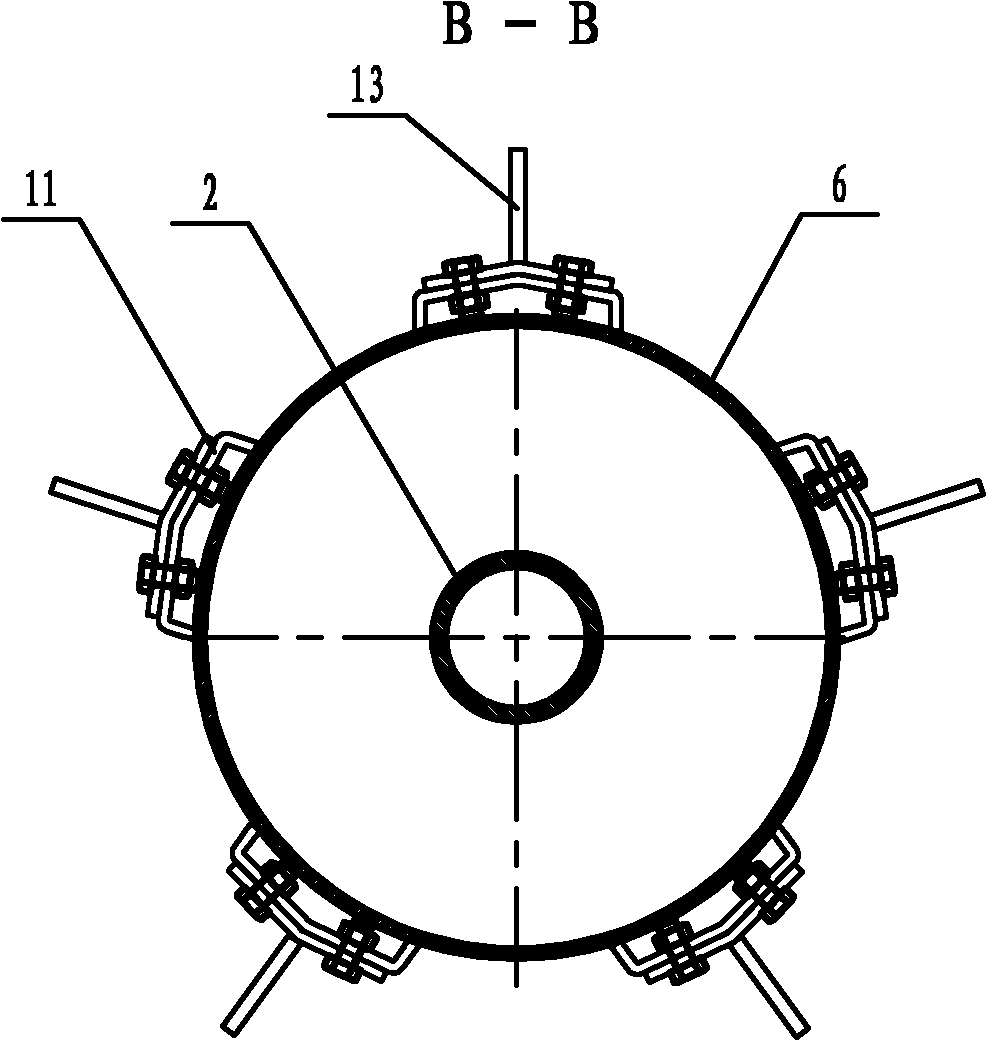

[0007] Specific implementation mode one: combine Figure 1 ~ Figure 3 Describe this embodiment, this embodiment includes front support semi-shaft 1, main shaft 2, screw blade 3, conical cylinder 4, fixed plate 5, closed cylinder 6, rear support semi-shaft 7, two sealing devices 8, a plurality of teeth Rod fixing plate 9, a plurality of arc gear rods 10, a plurality of plate tooth seats 11, a plurality of trapezoidal plate teeth 13 and a plurality of finger-shaped nail teeth 12, the rear end of the front support half shaft 1 is connected to the main shaft 2 through the connecting element The front end is connected, and the front end of the rear support half shaft 7 is connected to the rear end of the main shaft 2 through a connecting element. This design is convenient for disassembly and maintenance, which can reduce the maintenance cost of the user. The outer surface of each arc gear bar 10 is arc-shaped, A plurality of arc-shaped racks 10 are evenly distributed along the same...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 This embodiment will be described. In this embodiment, viewed from the front end of the main shaft 2 to the rear end, the direction of rotation of the plurality of arc-shaped gear bars 10 is opposite to the direction of rotation of the threshing cylinder. This design can reduce the resistance when the drum works. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 1 To describe this embodiment, the included angle α between each arc rack 10 of this embodiment and the center line N-N of the rack cylinder is 3°-6°. This design can effectively increase the speed of the crop moving backwards and reduce the resistance of the drum when it is working. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com