Automatic fumigation cabinet

An automatic, cabinet-shell technology, applied in the field of chemical treatment, can solve the problems of not easy to gasify, delaying the progress of the test, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to understand the present invention more clearly, describe the present invention in detail in conjunction with accompanying drawing and embodiment:

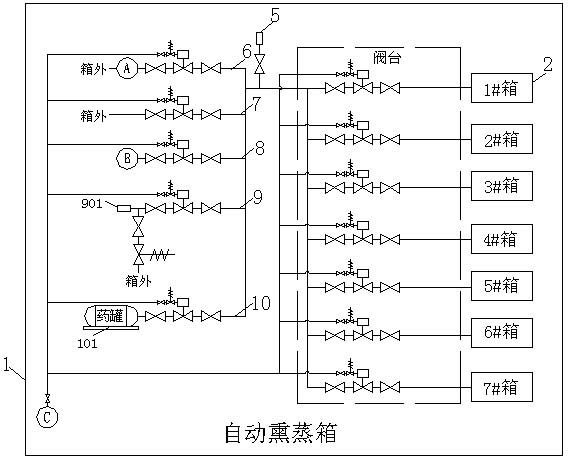

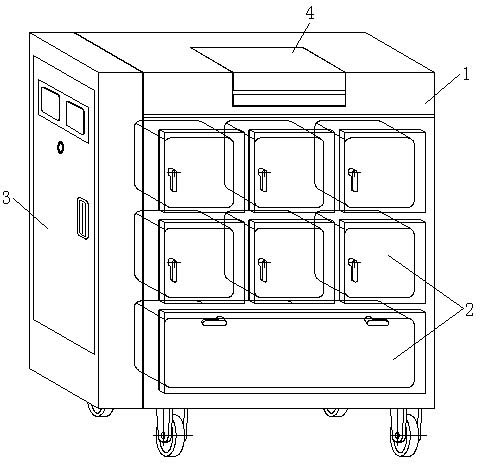

[0027] Such as Figure 1 to Figure 3 As shown, the automatic fumigation cabinet is characterized in that the automatic fumigation cabinet includes a cubic cabinet shell 1, and several heating cavities 2 are arranged in the cabinet shell 1, and the sealing door 21 of the heating cavity 2 is arranged on the front of the cabinet shell 1 , Manual valve A, pneumatic valve, manual valve B, electromagnetic valve are installed on the valve table in the cabinet shell 1, and a vacuum pump and pipeline are also installed in the cabinet shell 1;

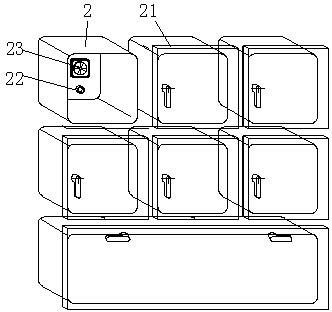

[0028] The inner wall of each heating chamber 2 is provided with an air inlet pipe mouth 22, and the air inlet pipe mouth 22 is connected to the air inlet pipe outside the heating chamber 2, and the manual valve A, the pneumatic valve, and the manual valve B are connected in se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com