Dust-free solid and liquid static mixing system

A technology of static mixing and static mixer, applied in fluid mixers, mixers, mixing methods, etc., can solve problems such as difficulty in forming a uniform solution state, harming the skin and respiratory system, and difficult to break particle clusters, so as to avoid Pollution of the environment and harm to the human body, saving of raw materials, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

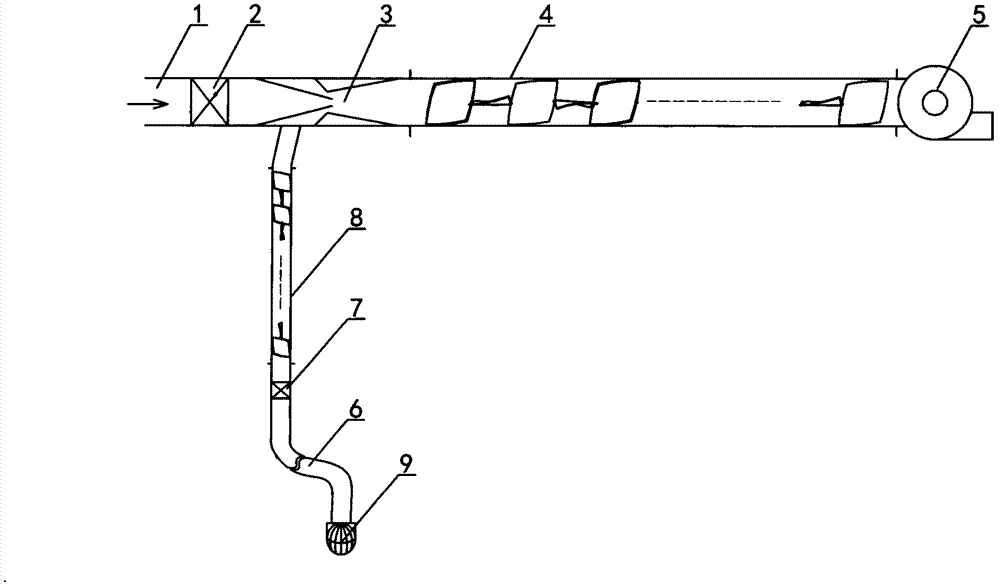

[0020] The solid-liquid dust-free static mixing system of the present invention is composed of a main fluid passage and a powder passage.

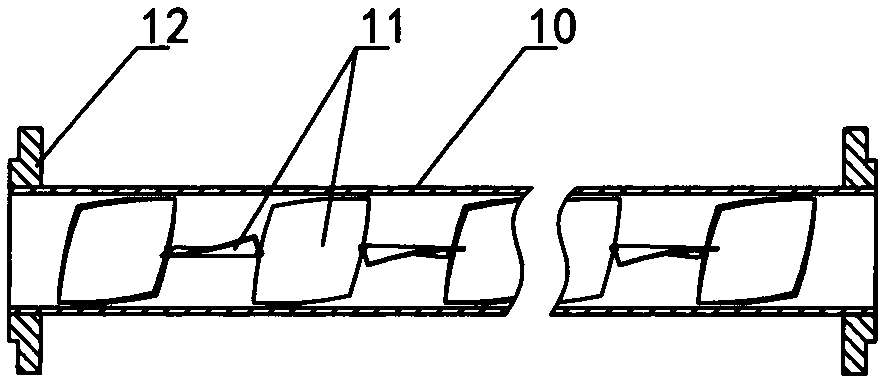

[0021] The main fluid channel is composed of a fluid inlet 1, a control valve 2, a jet negative pressure mechanism 3, a secondary static mixer 4 and a power pump 5 in series. (When the viscosity of the powdery material is mixed with the liquid is very small, the connection between the power pump 5 and the outlet of the secondary static mixer 4 is more conducive to mixing; when the viscosity of the powdery material is mixed with the liquid, the power pump 5 and the fluid inlet 1 connection is more conducive to mixing.)

[0022] The powder channel is composed of a feed pipe 6, a valve 7 and a first-stage static mixer 8 in series, and a mesh powder filter head 9 is provided at the feed port of the feed pipe 6. The discharge port of the primary static mixer 8 is connected with the jet inlet of the side wall of the jet negative pressure mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com