Device for realizing spray uniformity of MOCVD (Metal-Organic Chemical Vapor Deposition) and application of device

A uniform and uniform technology, applied in the field of MOCVD, can solve the problems of difficult processing, complex structure, and difficult to maintain stable use effect, and achieve the effect of uniform spraying and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings, and an embodiment of the present invention will be given.

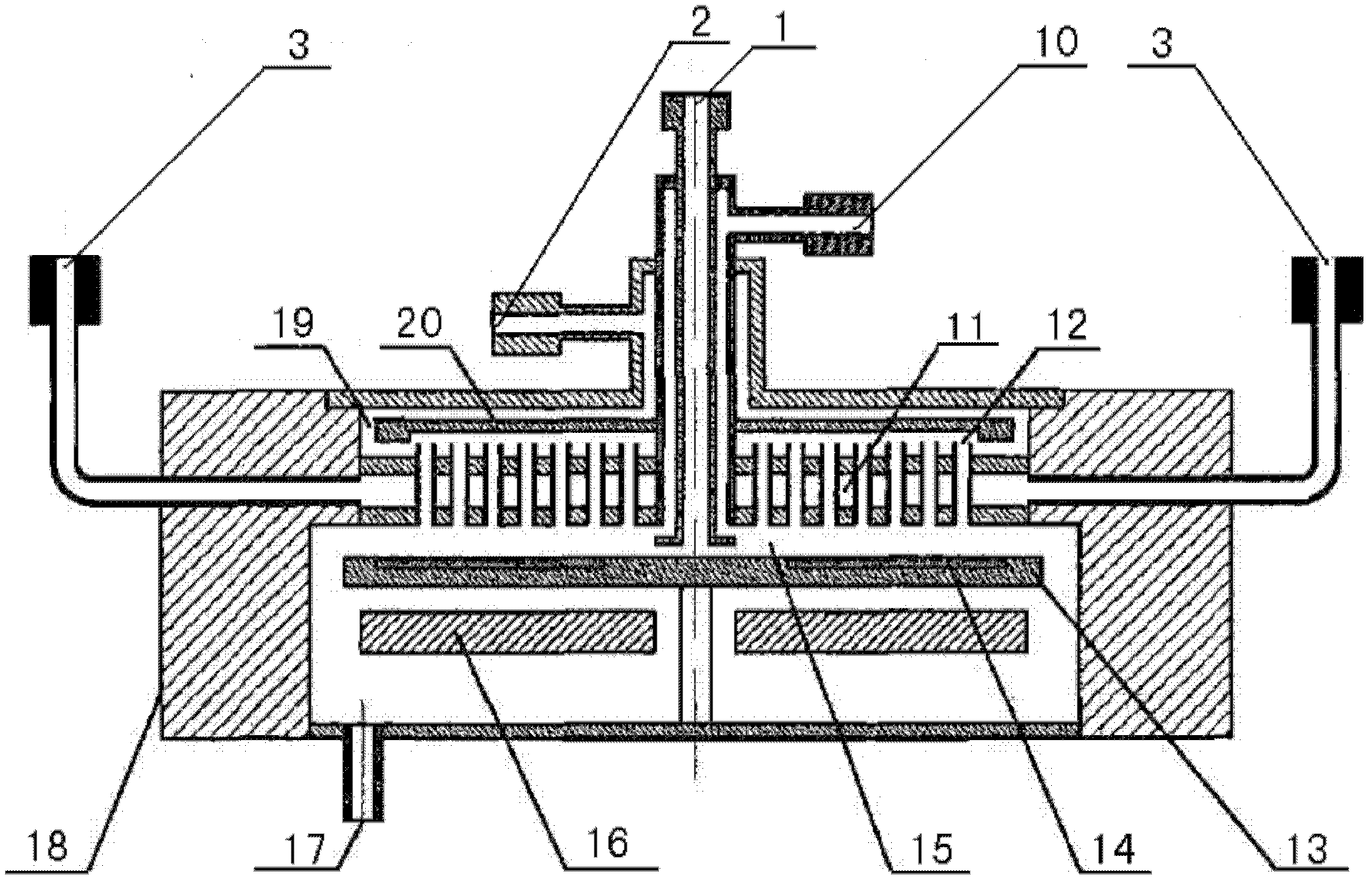

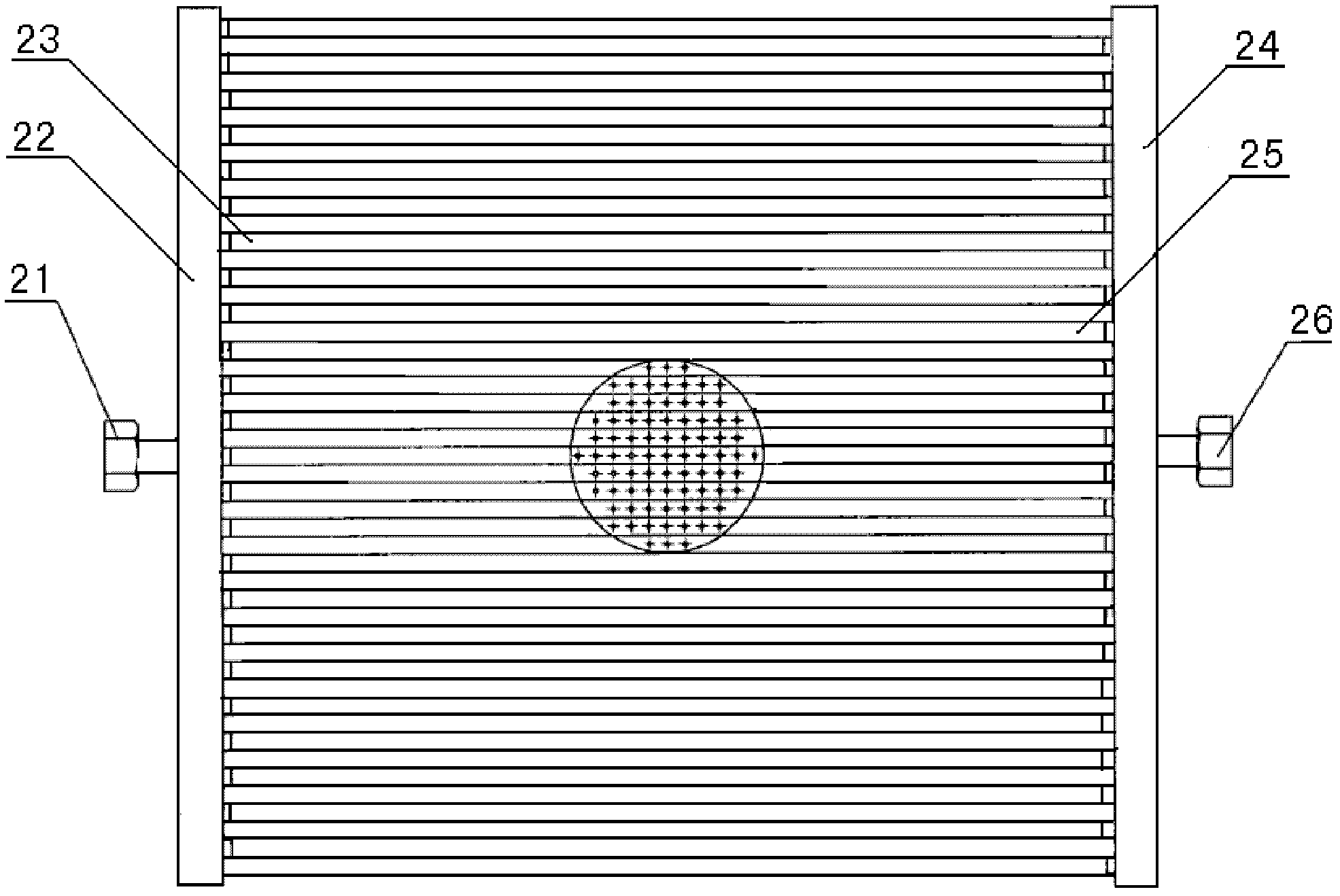

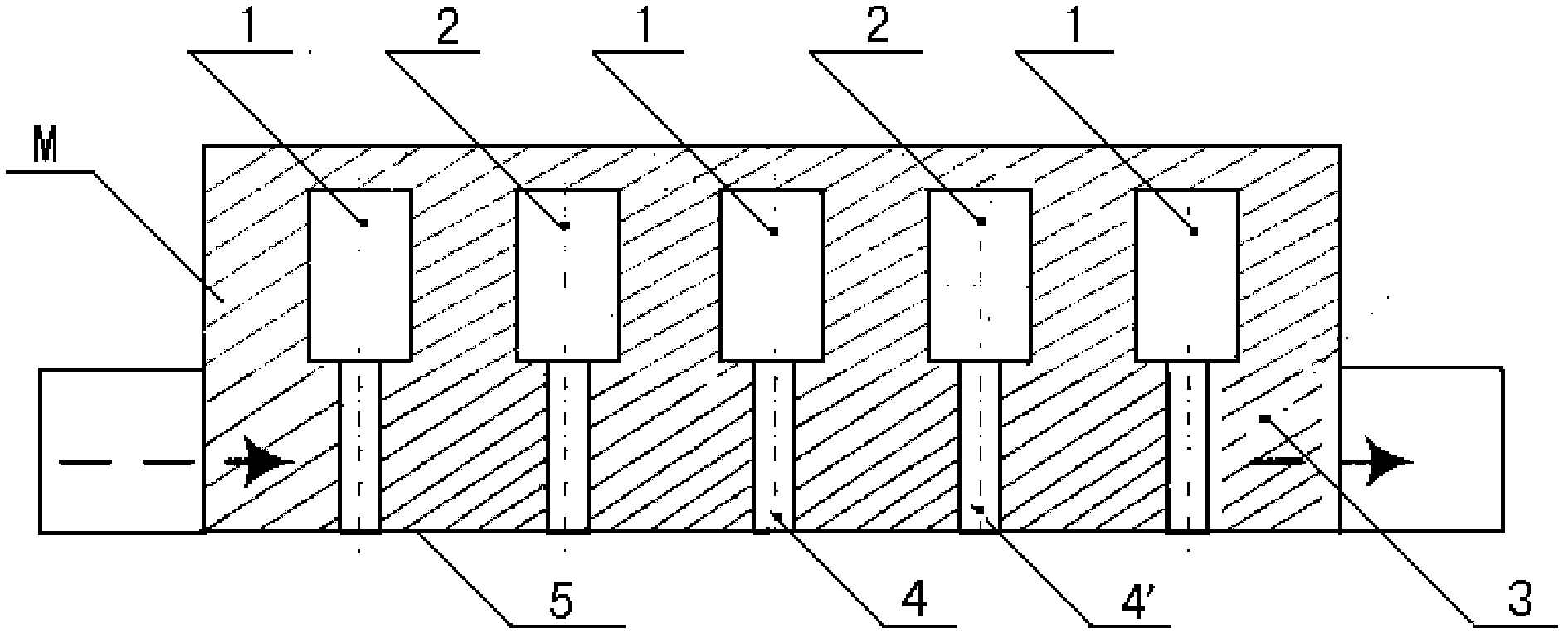

[0032] This device to realize the uniformity of MOCVD spraying, through the design and layout of micropores, constructs two or three layers of independent spatial channels in the spray head for simultaneously transporting the three fluids of A group gas, B group gas and cooling water respectively. Make each layer of independent space channel extend to the surface of the shower head body to form the interface respectively connected with the external gas supply source and cooling water; at the same time, through the design of the inner bottom of the group A gas delivery channel 1 and the B group gas delivery channel 2 respectively The microporous channels 4 and 4' leading to the bottom surface 5 of the shower head constitute the spray surface of the MOCVD spray outlet that can fully realize "uniform flow rate", "un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com