Circulating hot water heavy oil thermal recovery system for ultra-deep well and process thereof

A technology for thermal recovery of heavy oil and ultra-deep wells, which is applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc. It can solve problems such as affecting economic benefits and high production costs, and achieve strong operability and controllable temperature. Large range, good viscosity reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

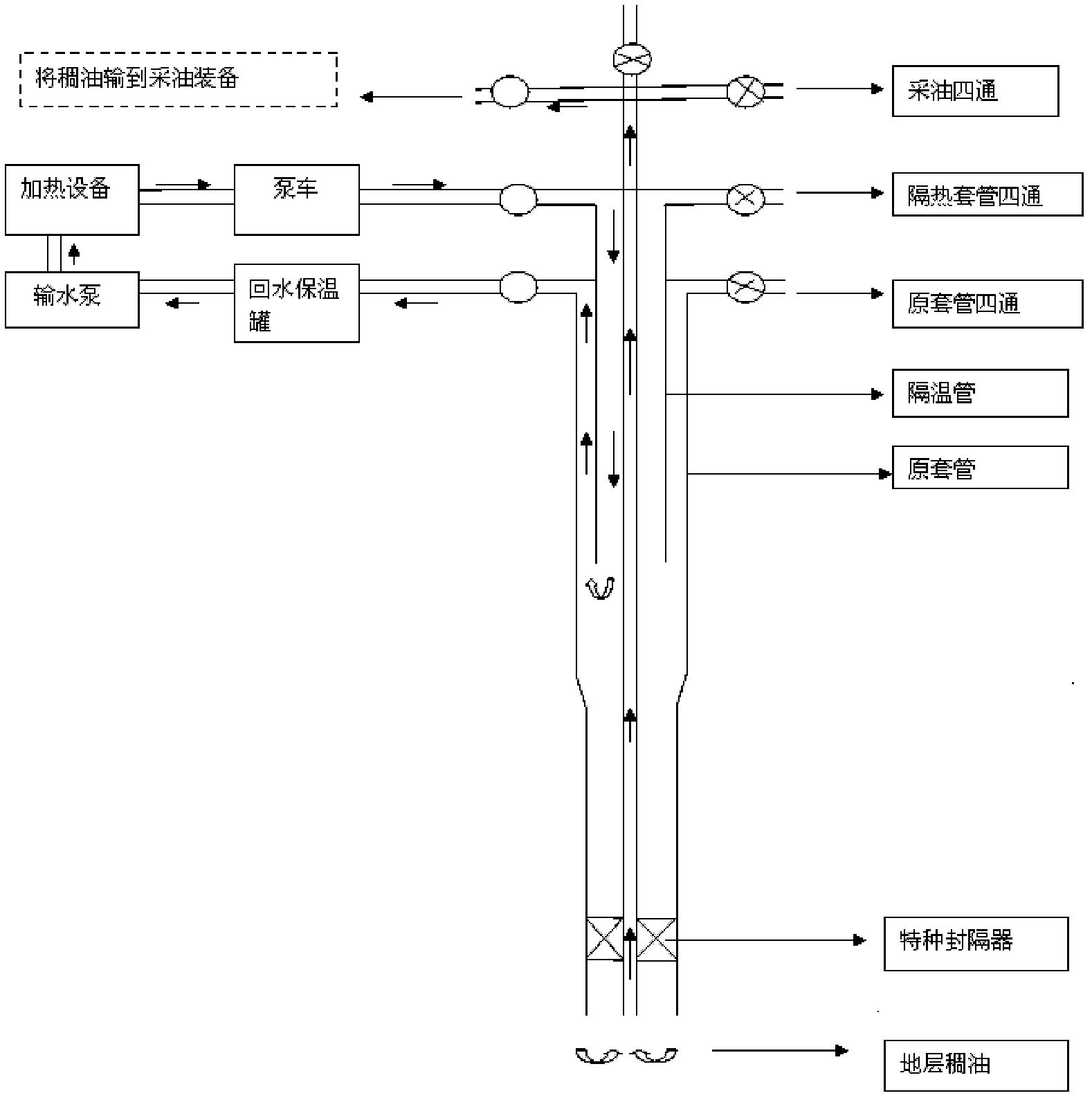

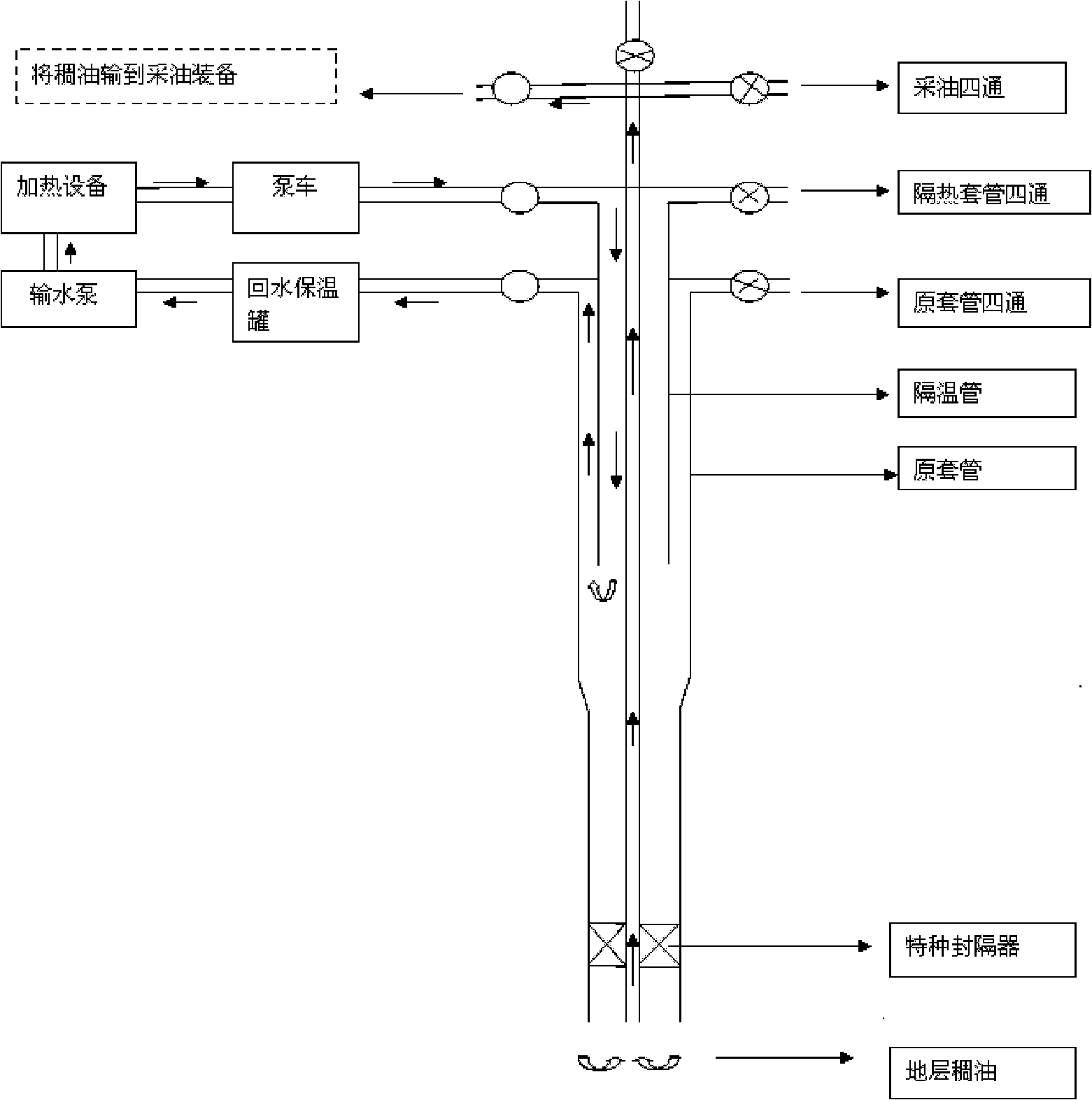

[0015] Below in conjunction with accompanying drawing, the present invention is described in detail, figure 1 It is a schematic diagram of the operating principle of a circulating hot water thermal recovery system for ultra-deep well heavy oil of the present invention. As can be seen from the accompanying drawings, the working principle of the present invention is to add a thermal insulation tube of a suitable depth on the basis of the original wellbore structure, to establish an inner annular space between the oil pipe and the thermal insulation tube and between the thermal insulation tube and the casing. The outer annular space of the inner and outer annular spaces communicates with each other at the lower end of the temperature insulating tube. Water can be heated on the ground by burning cheap fuel with ordinary heating equipment. The heated water is pumped into the inner annular space between the oil pipe and the thermal insulation pipe by an ordinary pump truck, heats t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com