Energy-saving type rolling rotor compressor

A rolling rotor type, compressor technology, applied in the field of compressors, can solve problems such as compressor liquid hammer, and achieve the effects of reducing exhaust gas temperature, realizing high-efficiency and energy-saving operation, and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

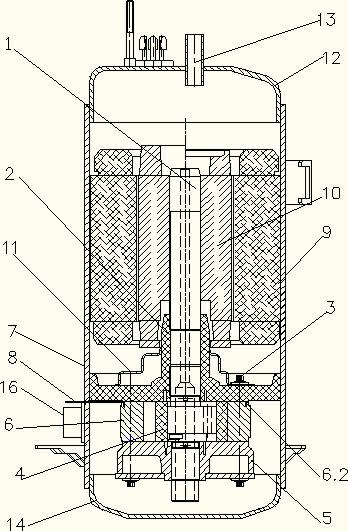

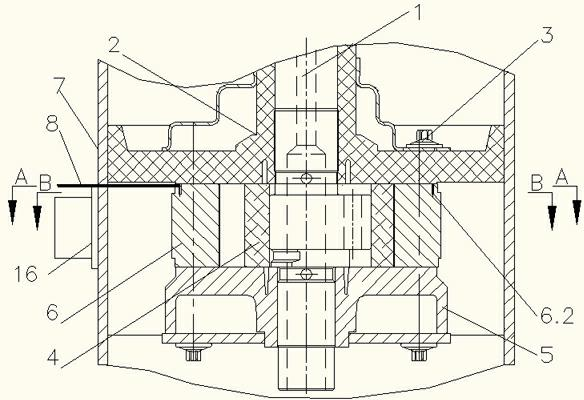

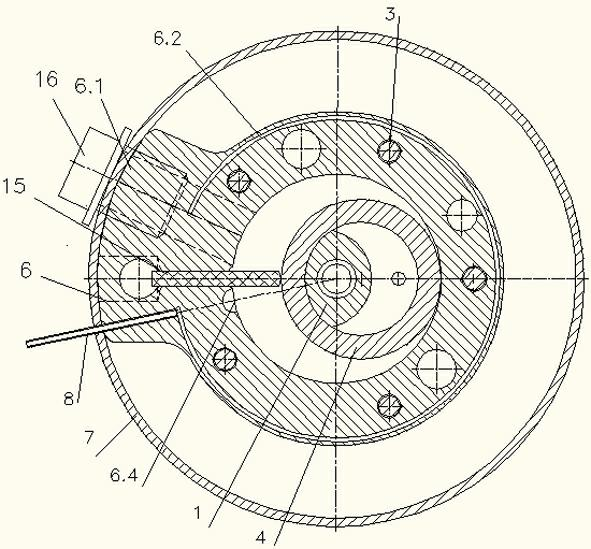

[0018] see figure 1 The energy-saving rolling rotor compressor includes a cylindrical casing 7, the upper end of the casing 7 is connected to the upper casing cover 12, the upper casing cover 12 is equipped with an exhaust pipe 13, and the lower end of the casing 7 is connected to the lower casing cover 14. A crankshaft 1 is arranged axially inside the housing 7, a motor composed of a rotor 10 and a stator 9 is installed on one side of the crankshaft 1, and an upper cylinder head 2, a piston 4 and a lower cylinder head are installed in sequence on the other side of the crankshaft 1. 5. The cylinder 6 is set on the outside of the piston 4, and the side of the housing 7 corresponding to the cylinder 6 is provided with a suction pipe 16. Cylinder 6 is ring-shaped, and one side of the outer periphery is provided with a bump; the cylinder on one si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com