Needle penetration measurement device and method for characterizing rheological behaviour of high-viscosity solid fuel ash

A solid fuel and measurement device technology, applied in the direction of measurement devices, flow characteristics, analytical materials, etc., can solve the problems of lack of quantified parameters, affecting prediction accuracy, and difficulty in viscosity characterization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

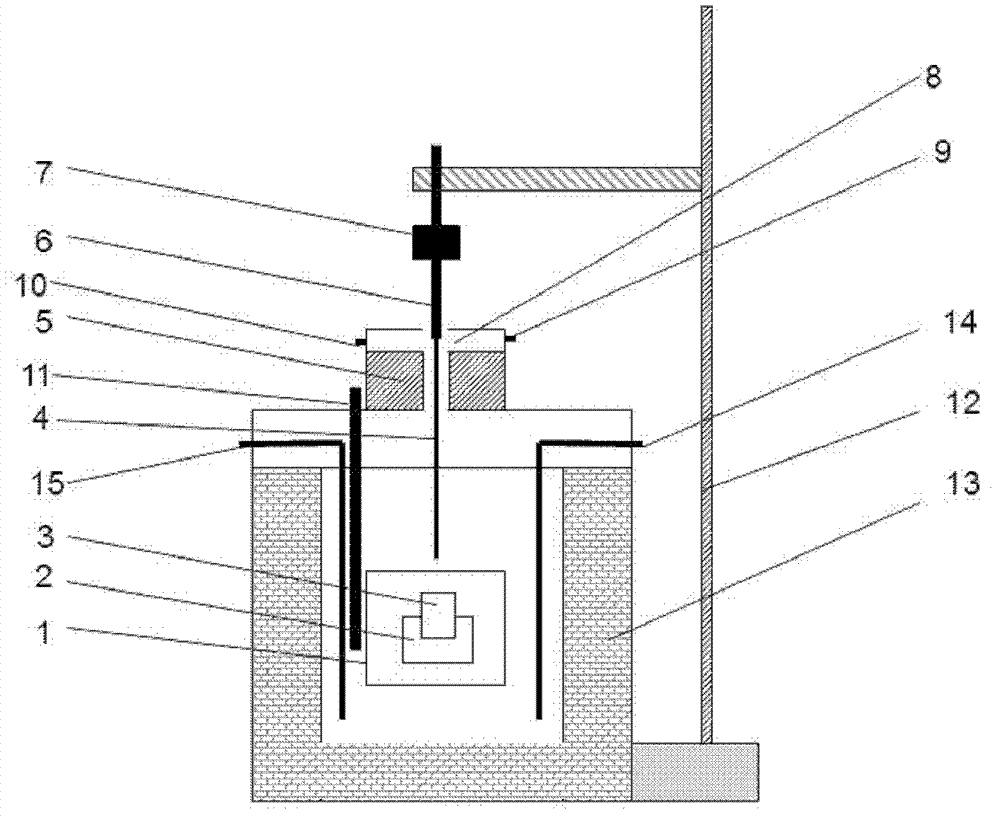

[0032] Fly ash from a pulverized coal boiler is measured by its melting property: the flow temperature is 1300°C, and its rheological parameters need to be measured at 1200°C. At this temperature, it is difficult to measure the viscosity with a high-temperature viscometer. In order to obtain the needle penetration parameters that characterize the rheology, the standard needle penetration time is set to 5s, and the ambient gas in the simulated boiler is air. Specific steps:

[0033] 1) Sample preparation: Pour the ash sample into the high-temperature-resistant sample container 3. After paving, the surface of the sample is 0mm from the edge of the sample container outlet. In the centered base 2 with grooves, after turning on the water cooling system of the cooling jacket 5, start the high-temperature furnace heating system, set the heating temperature to 1400°C, and use the thermocouple 11 to measure the temperature in the furnace; the furnace temperature rises to 1400°C After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com