Automatic testing device and method universally used for multiple bus processor modules

A technology of automatic testing device and processor module, which is applied in the direction of measuring devices, instruments, measuring electronics, etc. It can solve the problems that the test results cannot be automatically output and the test program cannot be loaded automatically.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The structural principle and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

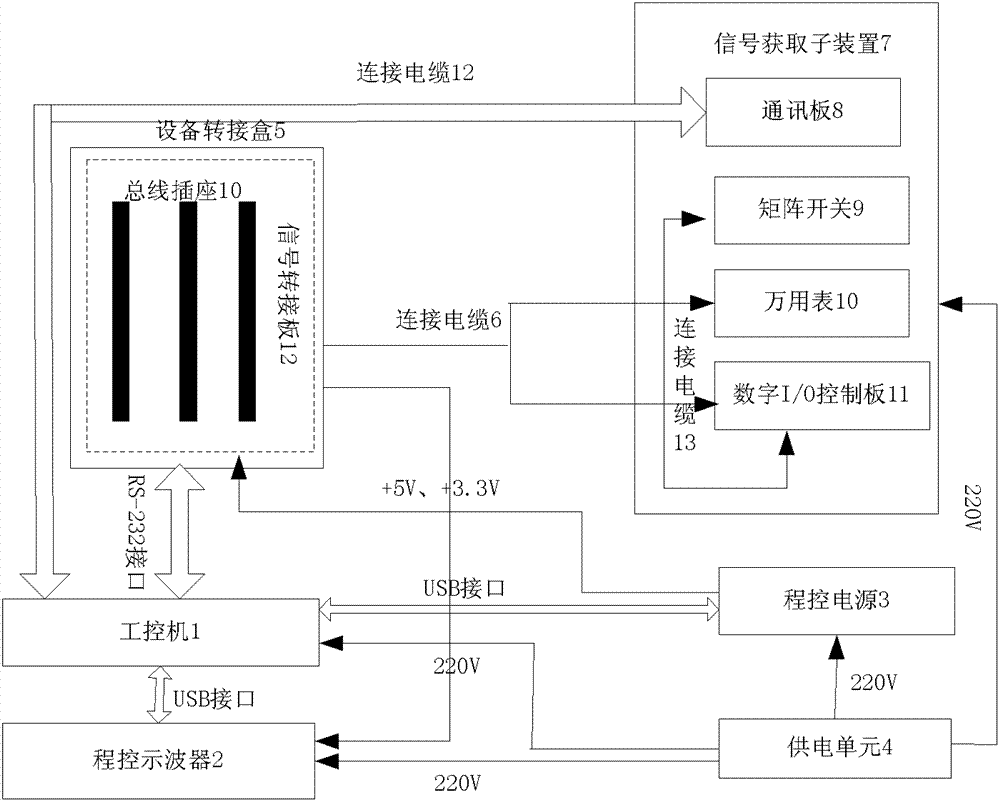

[0027] refer to figure 1 , a multi-bus processor module universal automatic test device, including a power supply unit 4, the power supply unit 4 is connected with the industrial computer 1, the program-controlled oscilloscope 2, the program-controlled power supply 3 and the power input end of the signal acquisition sub-device 7, the industrial computer 1 The RS-232 interface of the device is connected with the RS-232 interface of the equipment access box 5. The communication board 8, the matrix switch 9, the multimeter 10, and the digital I / O control board 11 are inserted into the main board of the signal acquisition sub-device 7 through the PXI bus, and the signal input and output interfaces of the equipment transfer box 5 are respectively connected to the signal through the connecting cable 6. The multimeter 10 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com