Exhaust turbine driven disk-type double-rotor permanent magnet generator

A permanent magnet generator and exhaust gas turbine technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of poor reliability, easy aging and failure of adhesives, easy damage, etc. Emission reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

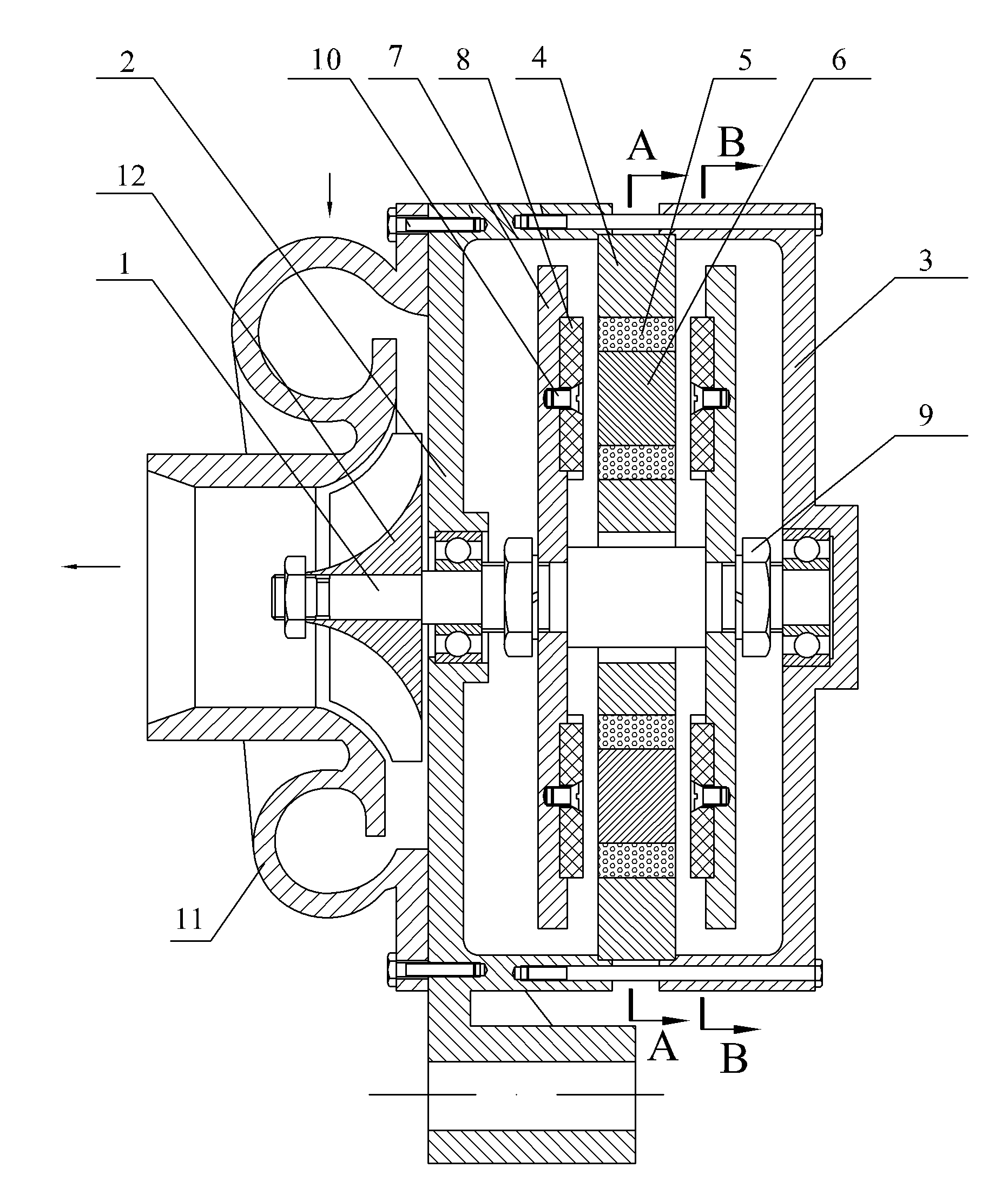

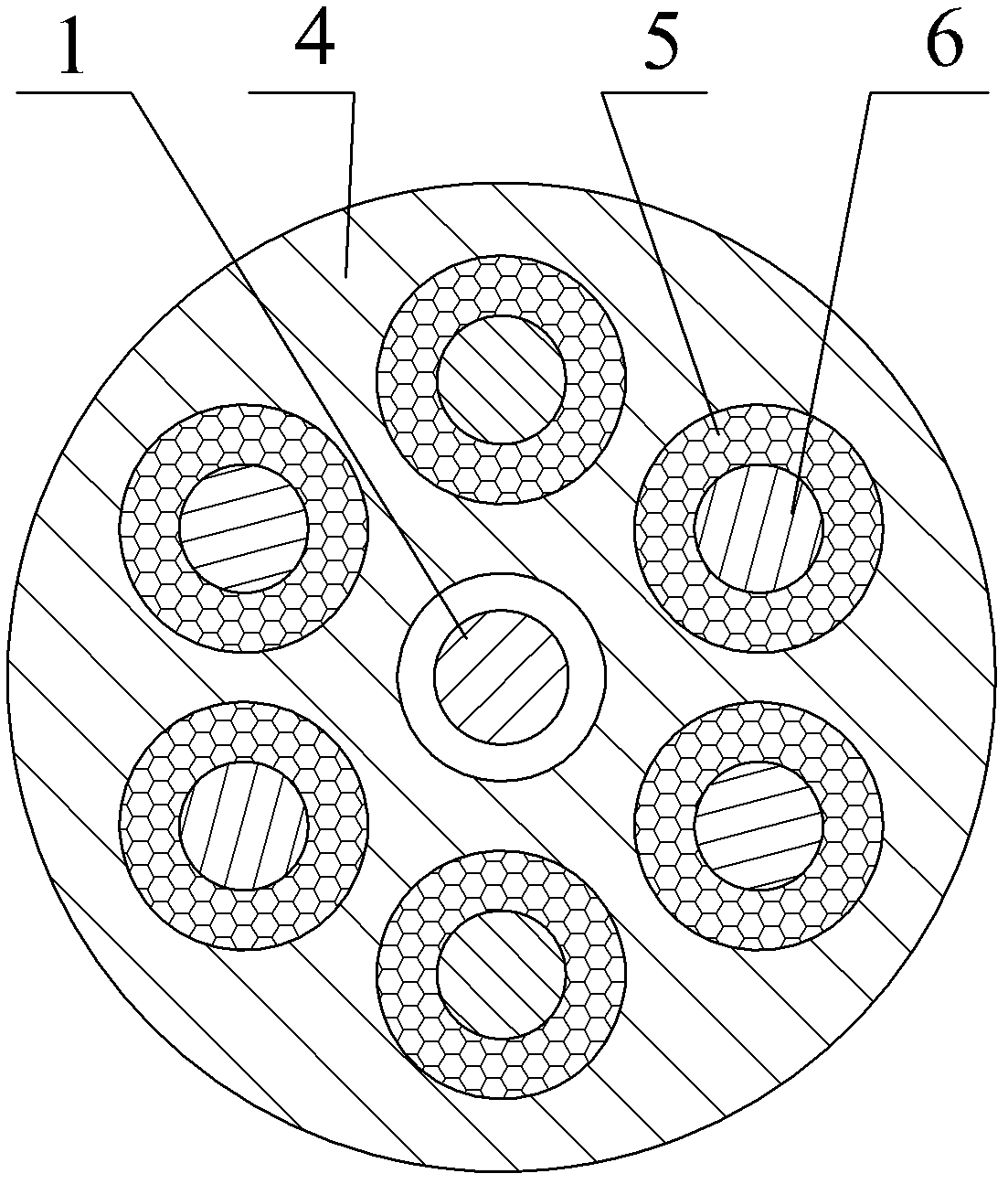

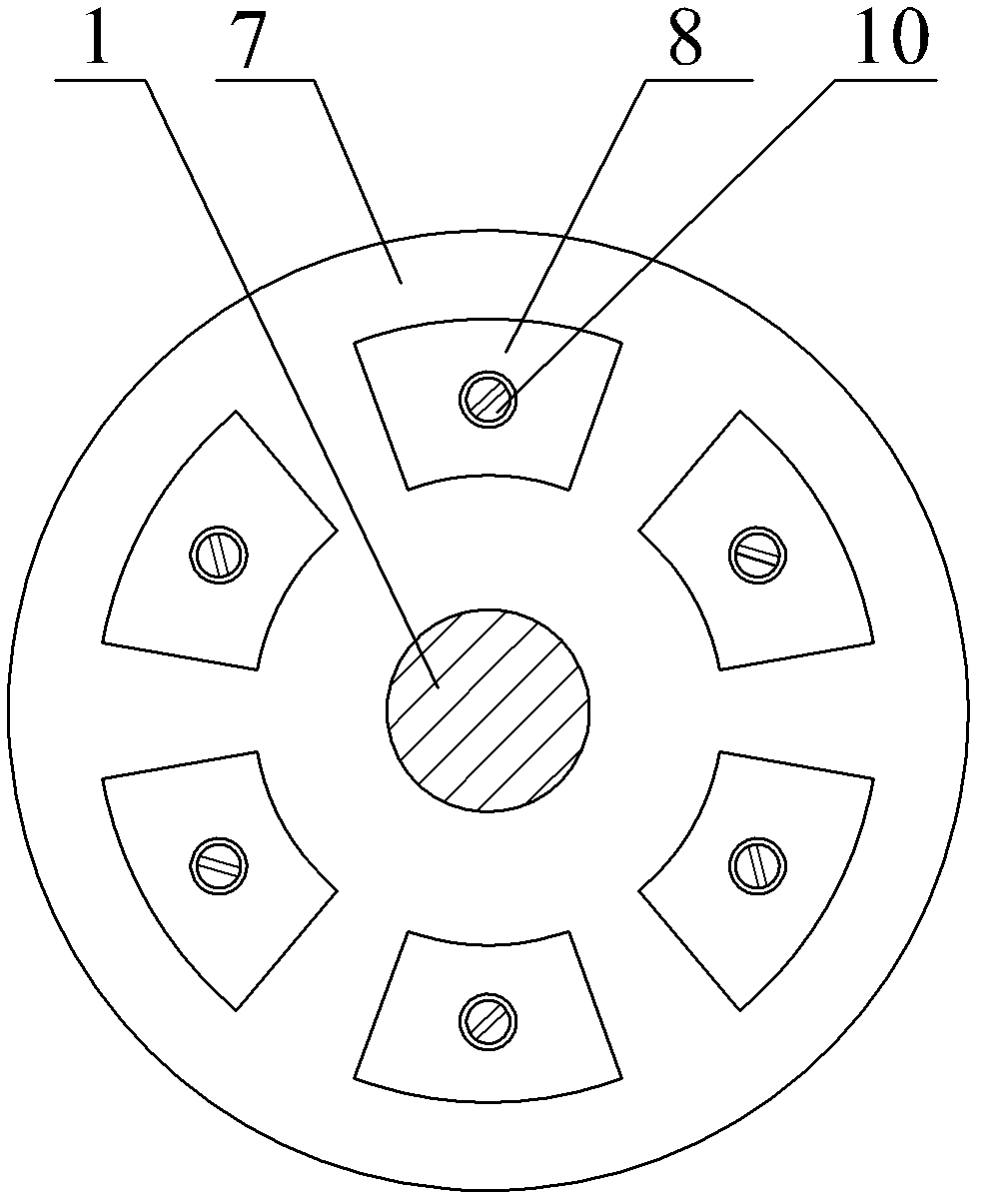

[0012] Attached below Figure 1-3 The present invention is described further:

[0013] The rotating shaft 1 of the generator and the rotating shaft of the turbine are the same shaft, and the front end cover 2 and the rear end cover 3 are all bearing mounted on the rotating shaft 1, and the stator is composed of a disc-shaped stator bracket 4 which is sleeved on the rotating shaft 1 and embedded in the The stator bracket 4 is composed of a plurality of iron cores 6 wrapped with armature windings 5, wherein the iron cores 6 are evenly distributed on the same circumference of the stator bracket 4, and the winding turns of each armature winding 5 are equal, and the stator bracket 4 The outer edge is clamped and fixed by the front end cover 2 and the rear end cover 3, and the stator support 4 is coaxial with the front end cover 2 and the rear end cover 3; a disc rotor is added on both sides of the stator support 4, and each disc rotor is It includes a rotor disk 7 fixedly set on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com