Fixture

A fixture and positioning disc technology, which is applied in the field of parts processing, can solve the problems of low part processing pass rate, high scrap, cost increase, etc., and achieve the effect of fast mass production progress, high processing pass rate and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention are described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

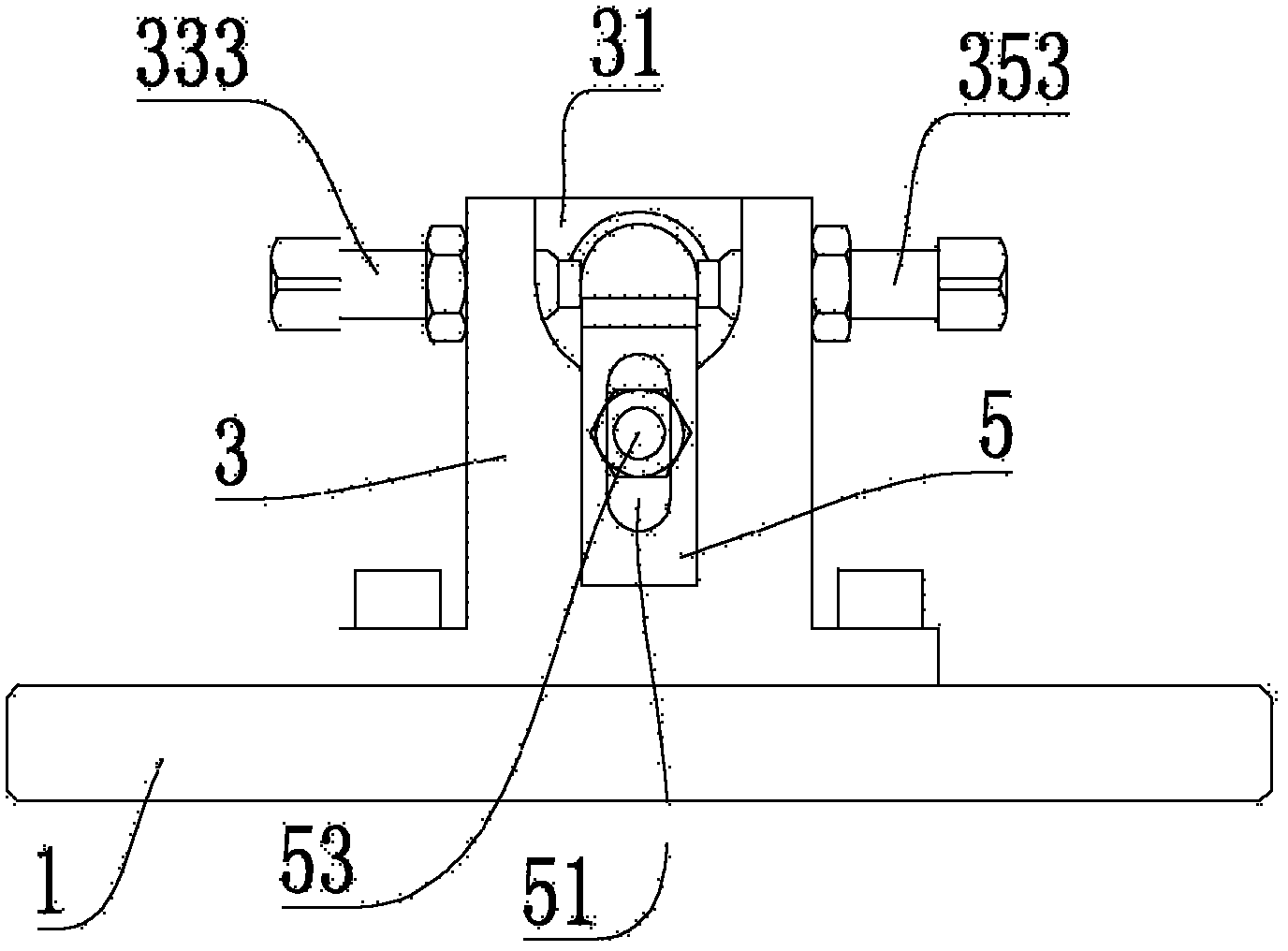

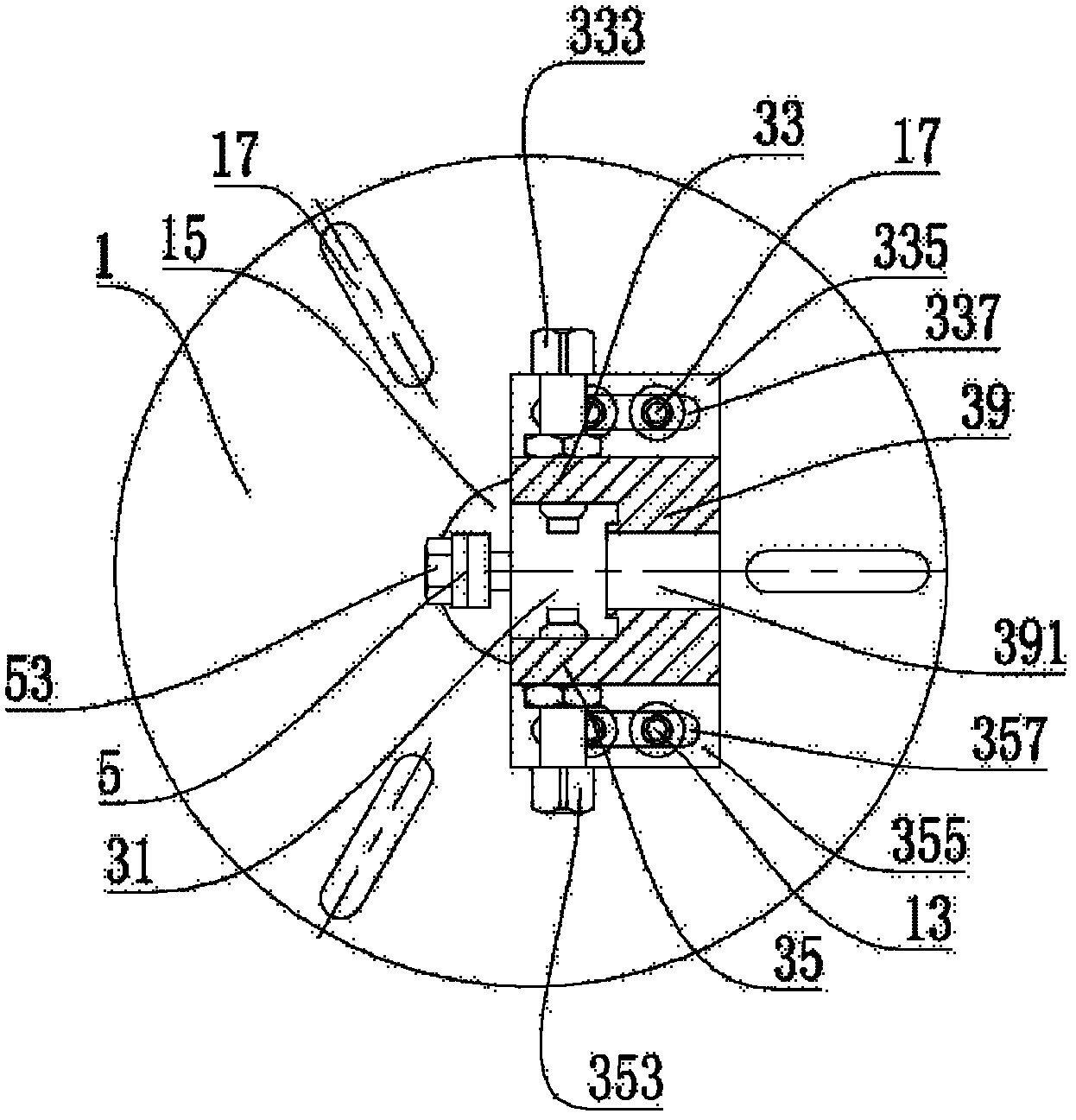

[0023] see figure 1 , the fixture includes a positioning plate 1 and a positioning block 3 fixedly mounted on the positioning plate 1 .

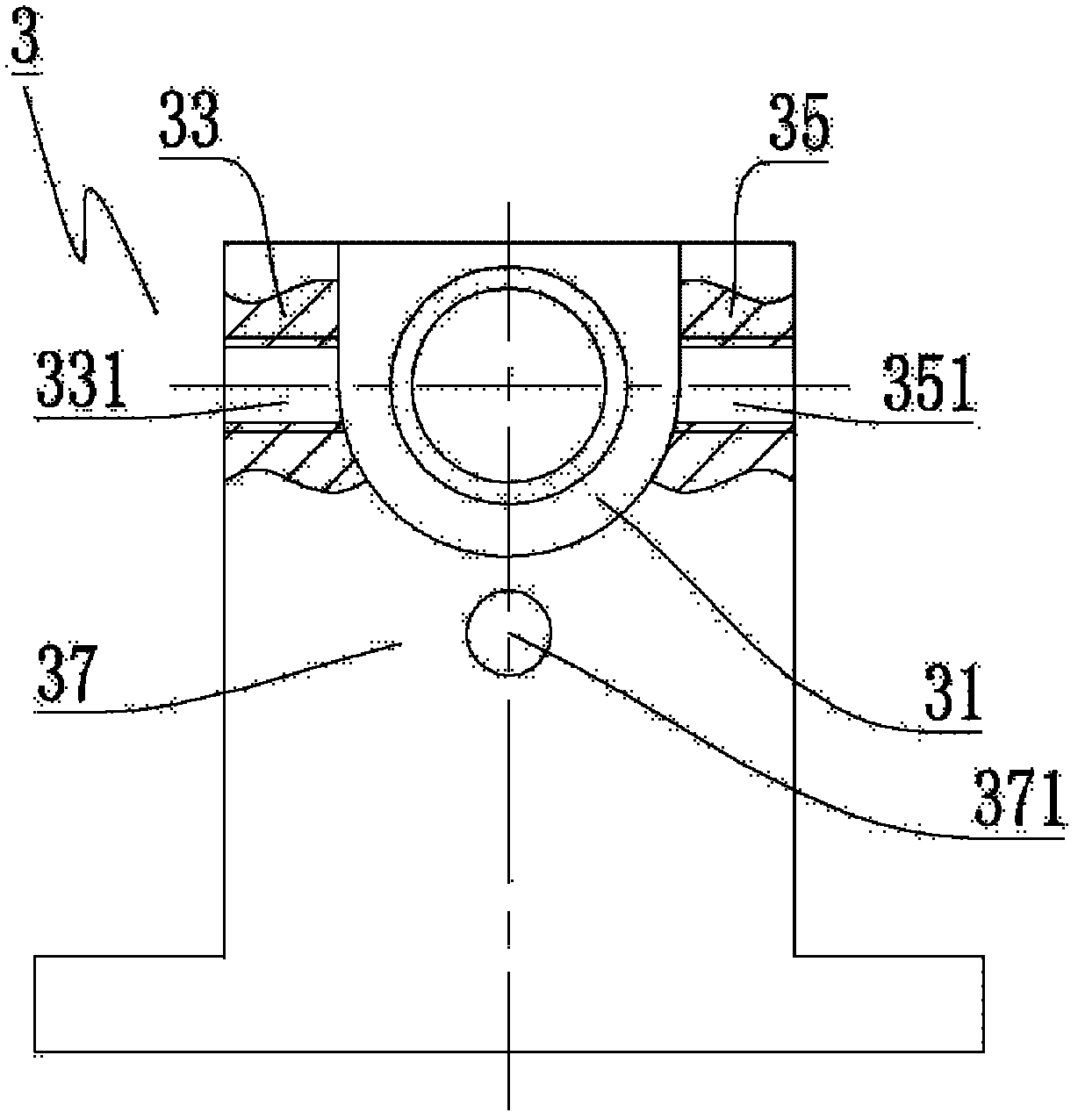

[0024] Please refer to figure 2 and image 3 , the positioning block 3 is provided with a positioning groove 31 . The positioning groove 31 is formed with a first wall 33 and a second wall 35 opposite to the first wall 33 . The first wall 33 and the second wall 35 are respectively provided with a first threaded hole 331 and a second threaded hole 351 penetrating the first wall 33 and the second wall 35 . The first threaded hole 331 and the second threaded hole 351 are respectively fitted with a first pressing screw 333 and a second pressing screw 353 . The first pressing screw 333 is also opposite to the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com