High frequency current commutation device for medical bag production

A high-frequency current and reversing device technology, applied in the field of machinery, can solve the problems of troublesome production process of medical bags, air leakage and scrapping of medical bags, low production efficiency, etc., achieve uniform force, stable current output, and simplify the production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

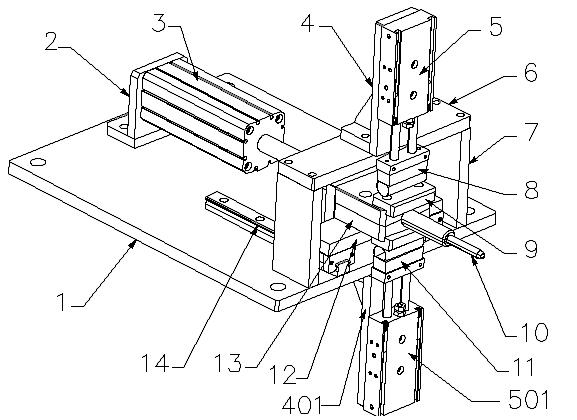

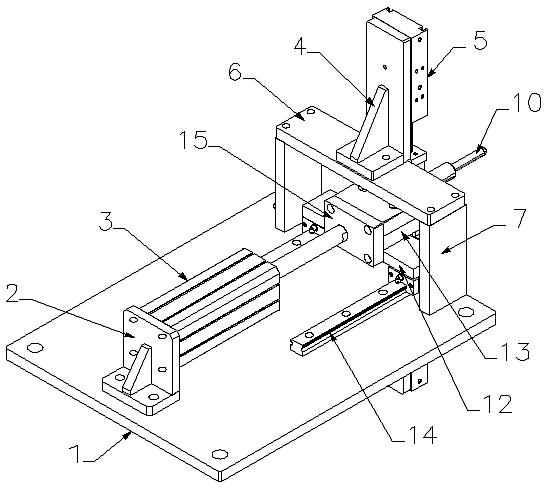

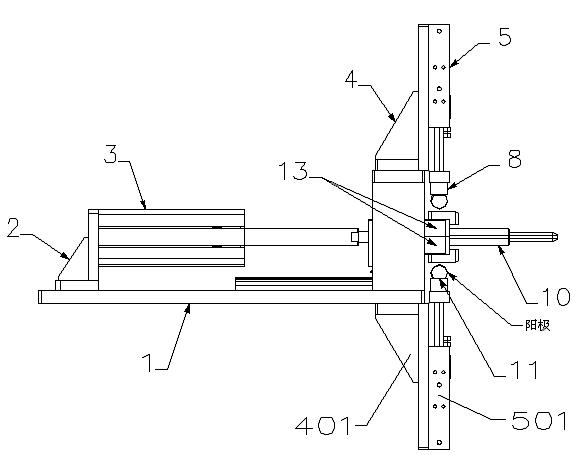

[0024] refer to figure 1 , figure 2 , image 3 As shown, a high-frequency current reversing device for producing medical bags includes a base plate 1, two side plates 7 are connected to the base plate 1, and a mounting plate 6 is fixed above the two side plates 7. The first bracket 4 is connected to the mounting plate 6, the first double-rod cylinder 5 is fixed on the first bracket 4, the first electrode 8 is connected under the first double-rod cylinder 5, and the bottom plate 1 is connected with a The second bracket 401, the second double-rod cylinder 501 is fixed on the second bracket 401, the second double-rod cylinder 501 is connected with the second electrode 11, the bottom plate, 1 is provided with two linear guide rails 14, The two linear guide rails 14 are connected with a slider mounting plate 12, and the slider mountin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com